Stretchable flexible conductive composite material as well as preparation method and application thereof

A flexible conductive and composite material technology, applied in the field of conductive composite materials, can solve the problems of non-isotropic conductivity, reduced conductive network pathways, and limited application range, etc., and achieves simple and easy preparation methods, difficult deposition, and no need for support structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

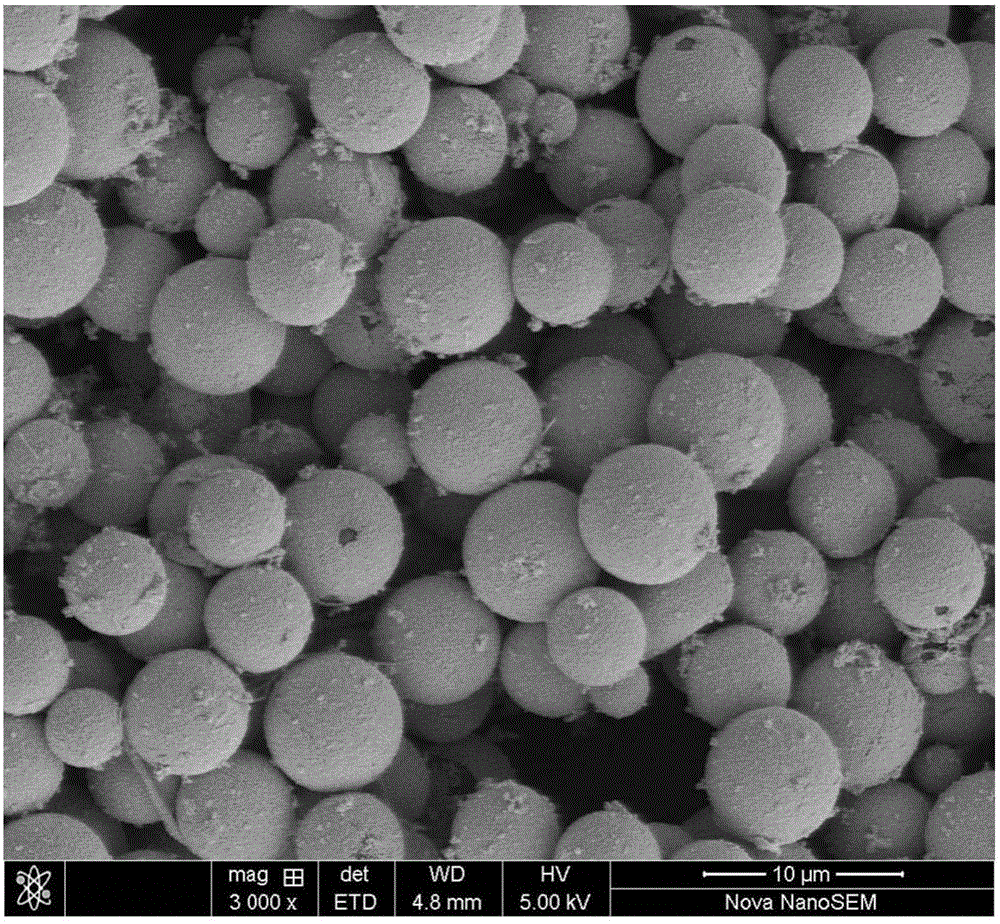

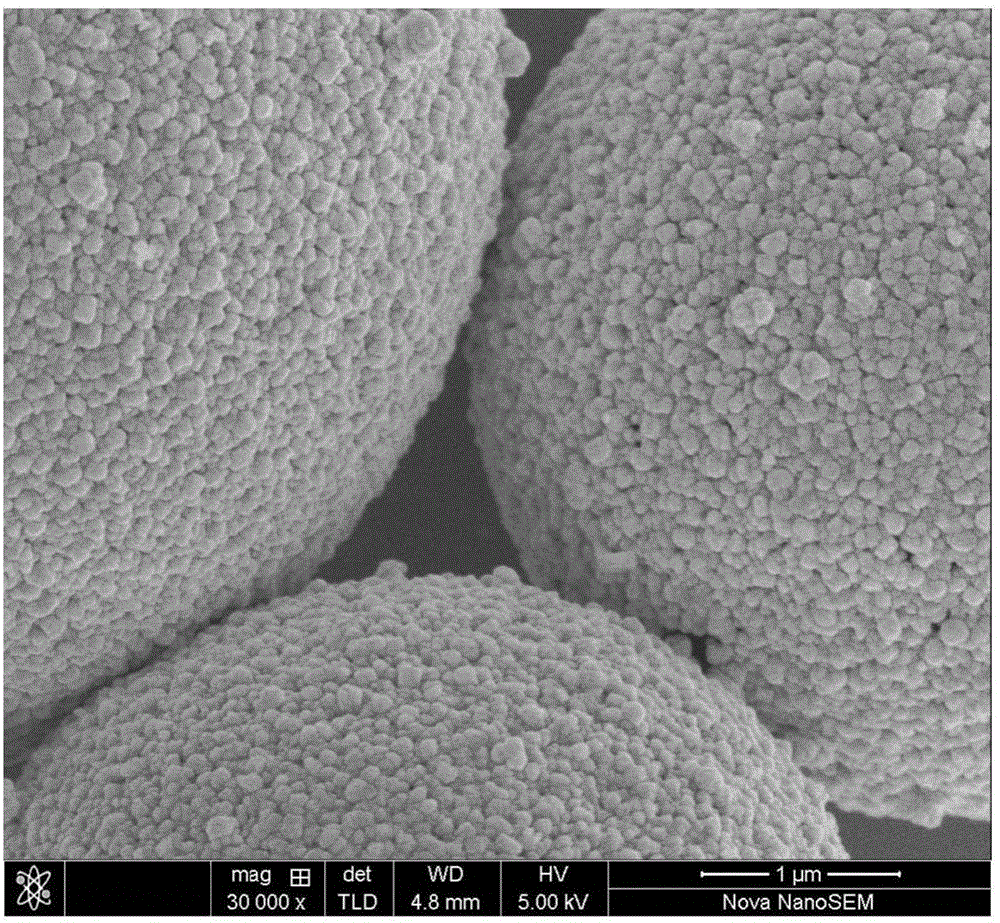

[0047] 1) With PS microspheres with a median particle size of about 5.5 μm as the core, the surface is plated with silver by an electroless plating process to obtain silver-plated conductive particles, such as figure 1 and figure 2 shown;

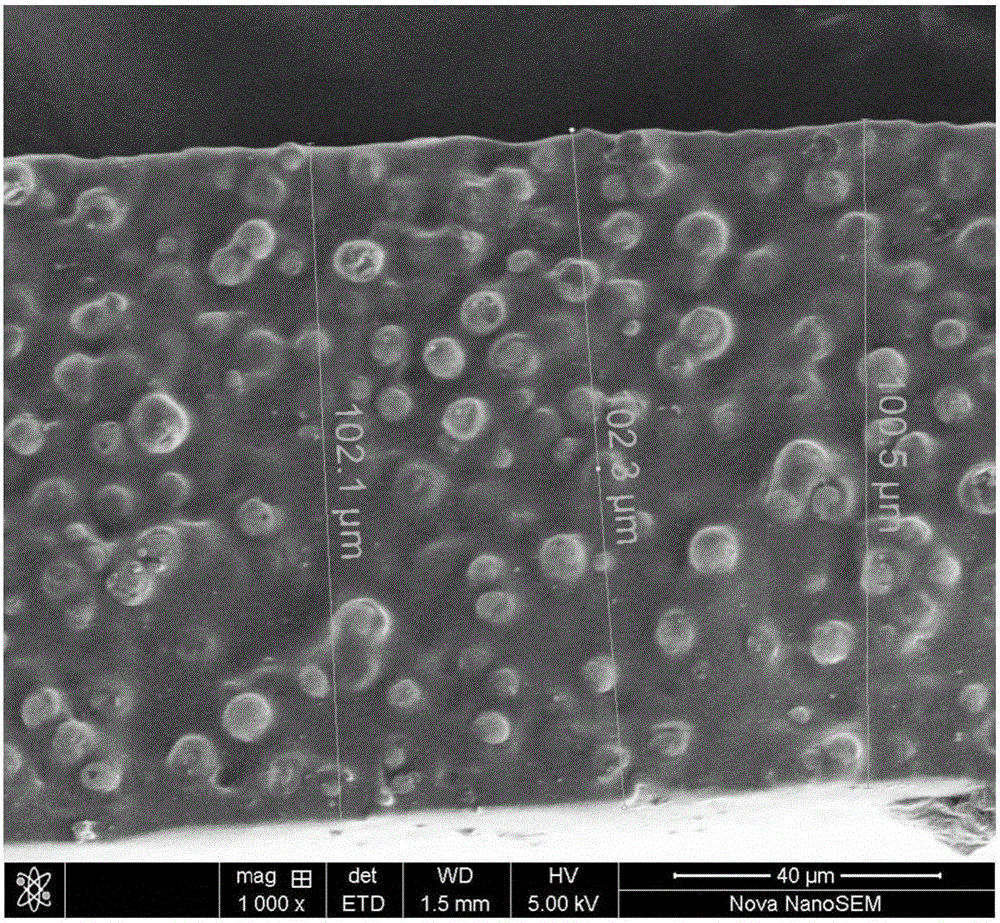

[0048] 2) Mix the silver-plated conductive particles obtained in step 1), PDMS prepolymer and n-hexane according to a mass ratio of 7:3:3.5, add a curing agent, stir and mix evenly at room temperature, and vacuumize for 30 minutes to remove air bubbles. Pour the mixture into a polytetrafluoroethylene mould, leave it at room temperature for 1 hour, and heat it in an oven at 80°C for 4 hours after n-hexane volatilizes to solidify the mixture. The stretchable and flexible conductive composite material is obtained. Its microstructure is as follows: image 3 and Figure 4 shown.

[0049] After testing and calculation, the conductivity of the prepared conductive composite material is 4.5×10 4 S / m, the maximum tensile strain reaches 100%. Cu...

Embodiment 2

[0053] 1) Using PDVB microspheres with a median particle size of about 1 μm as the core, silver-plated on its surface through an electroless plating process to obtain silver-plated conductive particles;

[0054] 2) Mix the silver-plated conductive particles obtained in step 1), TPU and toluene according to the mass ratio of 4:1:5, rotate and mix evenly at room temperature at high speed, and vacuumize for 10 minutes to remove air bubbles. The mixture was spin-coated on a silicon wafer at 1000 rpm for 30 s to obtain a thin film mixture. The silicon wafer sample was placed at room temperature for 24 hours, and the stretchable and flexible conductive composite film was prepared after the toluene in the mixture evaporated.

[0055] After testing and calculation, the conductivity of the prepared conductive composite material is 1.5×10 5 S / m, the maximum tensile strain reaches 150%.

Embodiment 3

[0059] 1) taking PAA microspheres with a median particle size of about 350nm as the core, and plating silver on its surface through an electroless plating process to obtain silver-plated conductive particles;

[0060] 2) Mix the silver-plated conductive particles obtained in step 1), SBS and methyl ethyl ketone at a mass ratio of 5:5:20, mechanically stir and mix evenly at room temperature, and vacuumize for 5 minutes to remove air bubbles. The mixture was poured into a glass watch glass, and left at room temperature for 48 hours until the methyl ethyl ketone in the mixture was volatilized to form a film naturally, that is, a stretchable and flexible conductive composite material was obtained.

[0061] After testing and calculation, the conductivity of the prepared conductive composite material is 8.5×10 3 S / m, the maximum tensile strain reaches 500%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com