XLPE electric cable accessory interface multi-stress coupling simulation test device and method

A cable accessory and simulation test technology, applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., to avoid slippage and achieve the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

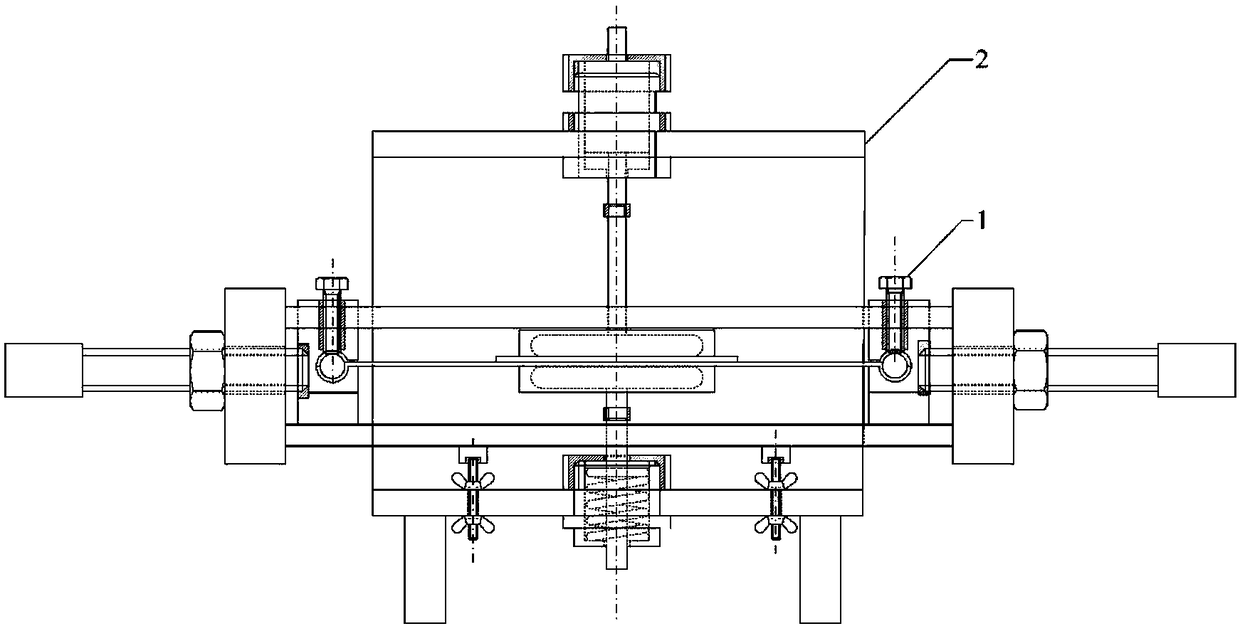

[0038] Taking the interface multi-stress coupling simulation device during normal operation of XLPE cable accessories as an example, the technical solution involved in the present invention is described in detail. The structural diagram is as follows figure 1 As shown, the device can apply electrical stress, interfacial pressure, and tensile stress simultaneously.

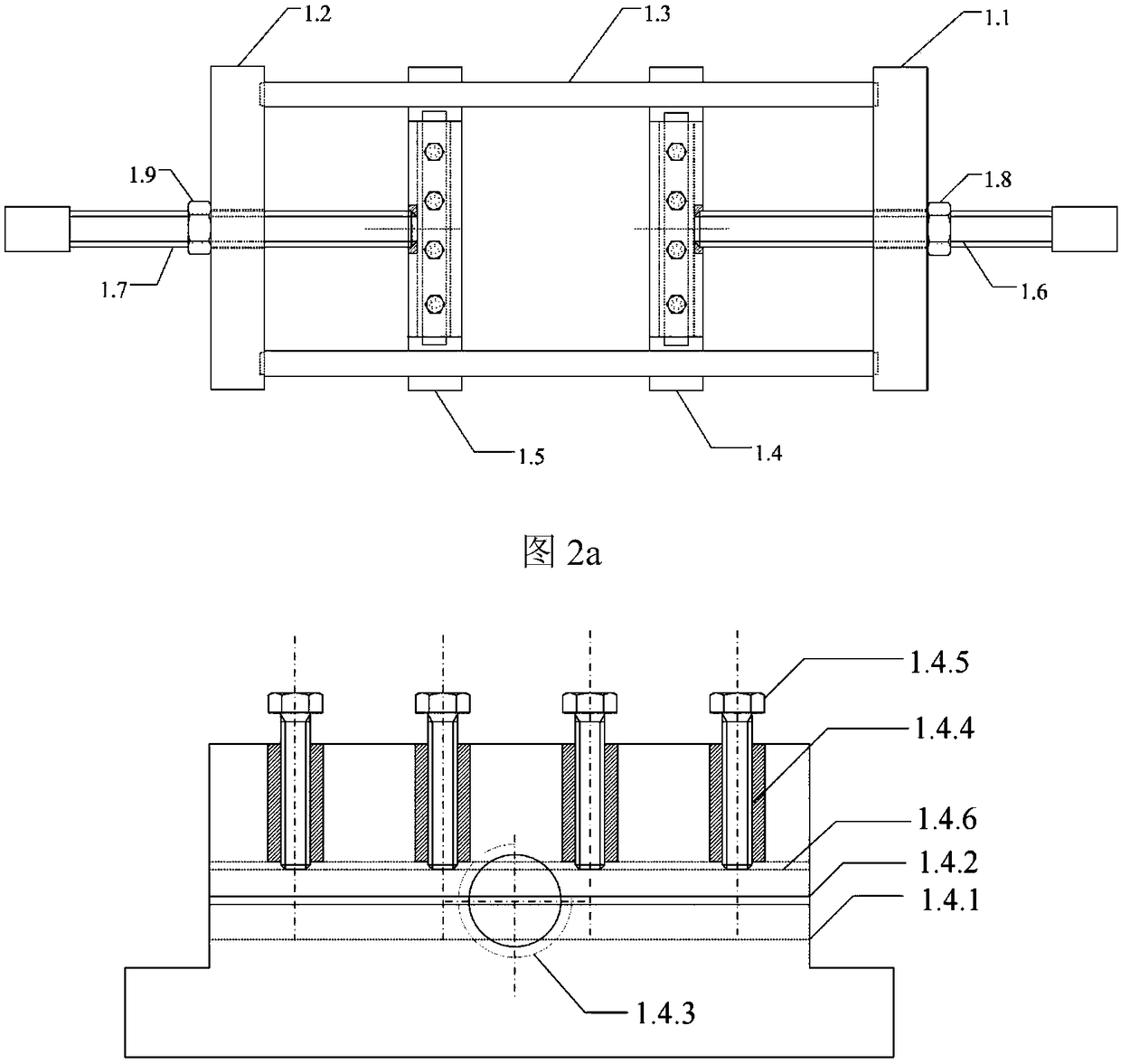

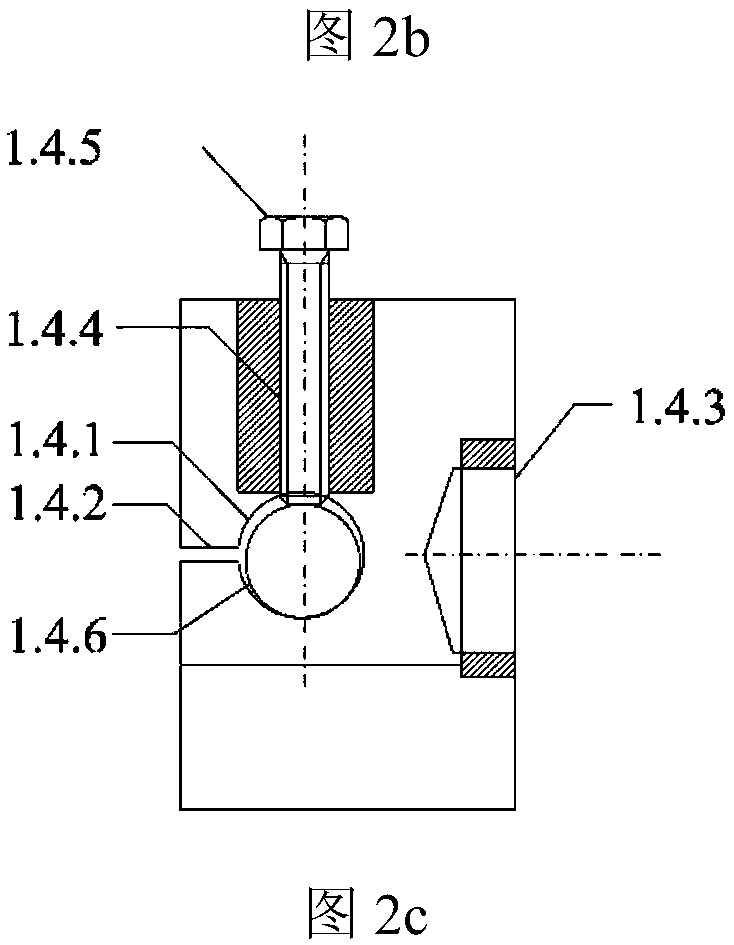

[0039] refer to figure 1 , figure 2 and image 3 As shown, the XLPE cable accessory interface multi-stress coupling simulation test device of the present invention adopts a tensile stress application device 1 and a U-shaped electrical stress and interface pressure application device 2. First, the rubber test piece 2.5 is passed through the tensile stress application device 1 twice. The first clamp 1.4 and the second clamp 1.5 on the side are fixed on the tensile stress application device 1, and the tension is adjusted by the first hexagonal nut 1.8 and the second hexagonal nut 1.9 on both sides of the tensile st...

Embodiment 2

[0043] Taking the multi-stress coupling simulation device for XLPE cable accessory interface defect discharge as an example, the technical solution involved in the present invention is described in detail. The device can apply discharge stress, interface pressure and tensile stress at the same time.

[0044] The structure of the multi-stress coupling simulation device in the XLPE cable accessory interface defect discharge in this example is similar to the structure in the first embodiment, using the tensile stress application device 1 and the U-shaped electrical stress and interface pressure application device 2, the tensile stress Applicator 1 and the two devices cooperate in exactly the same way, but U-shaped electric stress is slightly different from interface pressure applicator 2. The difference is reflected in the treatment of the sample. In this example, the lower surface of the cross-linked polyethylene test piece 2.4 is artificially manufactured with a cuboid depressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com