Stretchable flexible supercapacitor and preparation method thereof

A supercapacitor, flexible technology, applied in stretchable flexible energy storage elements and its preparation, stretchable flexible supercapacitor and its preparation field, can solve the poor electrochemical performance of stretchable flexible supercapacitor, gel electrolyte and The poor adhesion of electrode materials and the inability to meet the requirements of stretchable devices have achieved the effect of easy industrial production, low cost and high stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0067] Embodiment 1~6 polyacrylamide gel preparation embodiment

Embodiment 1

[0069] (1) Preparation of water-soluble acrylate-terminated polyurethane macromolecular crosslinking agent

[0070] With 10.0g (0.01mol) polyethylene glycol 1000 as the soft segment, 13.34g (0.06mol) isophorone diisocyanate and 2.68g (0.02mol) 2,2-dimethylolpropionic acid chain extender as Hard segment, with 0.08g of dibutyltin dilaurate as a catalyst, pre-polymerized at 80°C for 3 hours in an argon atmosphere and acetone solvent; The pre-polymerized product was reacted for 12 hours to end-cap, and 2.02 g (0.02 mol) of triethylamine was used to react at room temperature for 1.5 hours to neutralize the end-capped product. Finally, the neutralized product was dissolved with deionized water, and the acetone solvent was removed in vacuum to obtain a water-soluble acrylate-terminated polyurethane (abbreviated as "crosslinking agent-1");

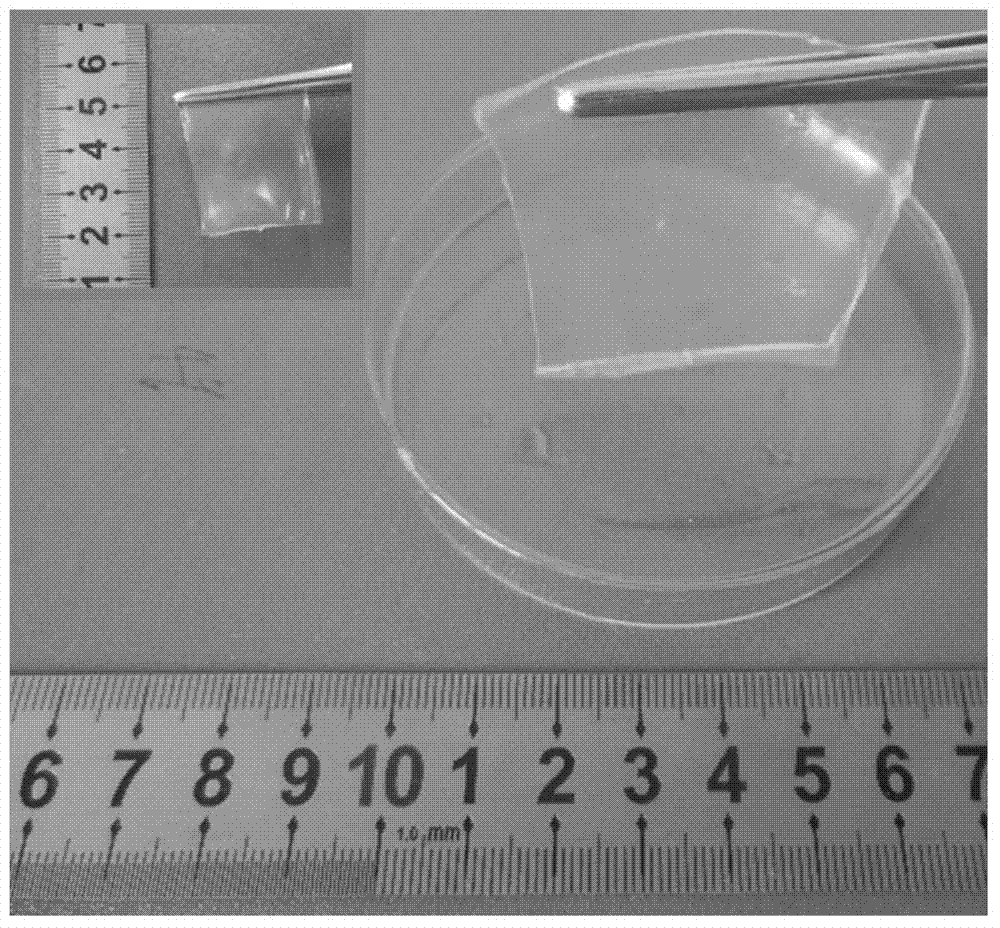

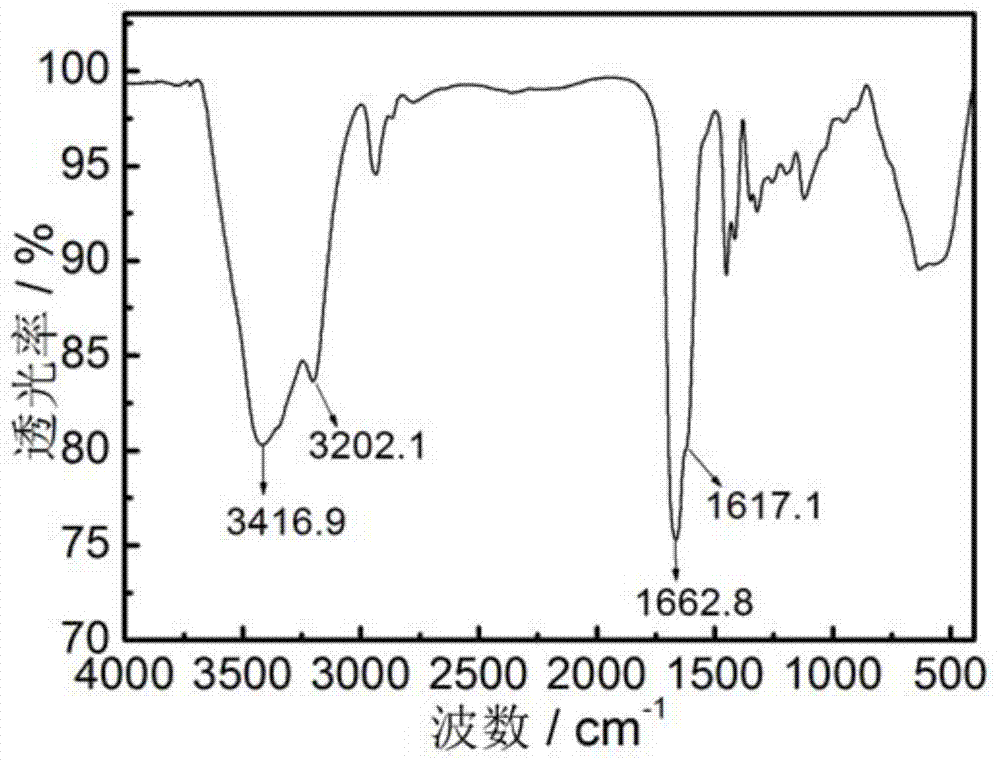

[0071] (2) Preparation of stretchable polyacrylamide gel

[0072] Stir and mix 0.04g of "Crosslinking Agent-1" obtained from step (1), 1.0g of ...

Embodiment 2

[0081] (1) Preparation of water-soluble acrylate-terminated polyurethane macromolecular crosslinking agent

[0082] With 20.0g (0.01mol) ethylene oxide-propylene oxide block copolymer diol 2000 as soft segment, with 17.74g (0.06mol) 4,4'-dicyclohexylmethane diisocyanate and 2.68g (0.02 mol) 2,2-dimethylol propionic acid chain extender is the hard segment, with 0.08g of dibutyltin dilaurate as the catalyst, pre-polymerized at 80°C in an argon atmosphere and butanone solvent for 4 hours; with 3.9g (0.06mol) 2-hydroxyethyl methacrylate was reacted at 45°C for 12 hours to block the prepolymerized product, and 1.18g (0.02mol) trimethylamine was used to react at room temperature for 1.5 hours to neutralize the blocked product . Finally, the neutralized product was dissolved with deionized water, and the methyl ethyl ketone solvent was removed in vacuum to obtain a water-soluble acrylate-terminated polyurethane macromolecular crosslinking agent (abbreviated as "crosslinking agent-2"...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com