Four-wheeled film mulching machine

A laminator and sprocket technology, which is used in plant protection covers, devices for trapping or killing insects, fertilizer distributors, etc. The effect of uniformity, saving manpower and material resources, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

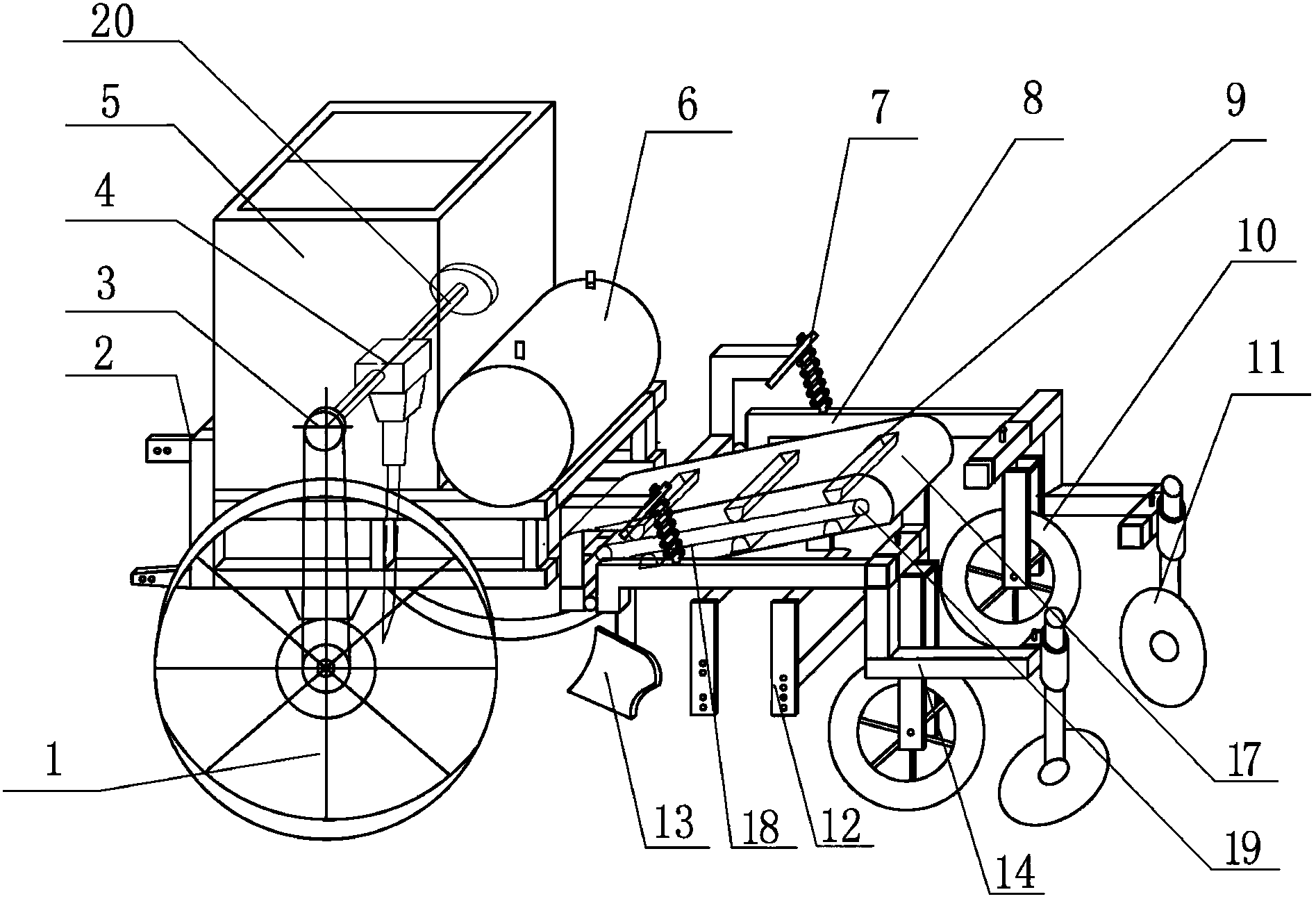

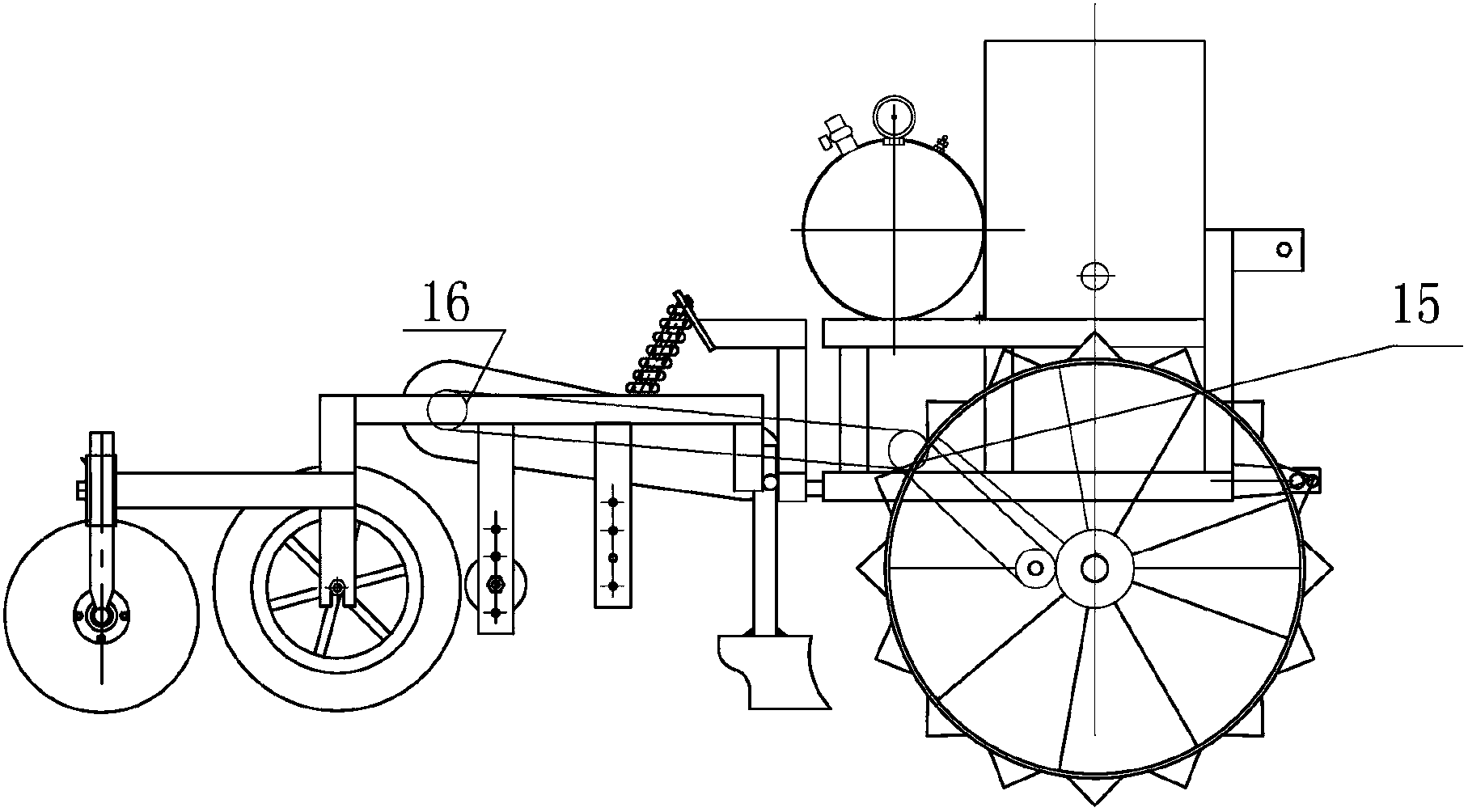

[0015] Such as Figure 1-2 As shown, a four-wheel laminating machine according to an embodiment of the present invention includes a traction device 2. Two ground wheels 1 are connected below the traction device 2, and the two ground wheels 1 are connected by a rotating shaft. There are two fertilizer boxes 5 side by side above the device 2. The fertilizer box 5 is equipped with a fertilizer discharging device 4, and the lower end of the fertilizer discharging device 4 is provided with a funnel. The fertilizer discharging device 4 is provided with a fertilizer adjustment knob, and two fertilizer The box 5 can be filled with different fertilizers, and the fertilizer adjustment knob can effectively adjust the quantity and speed of fertilizer application. The upper ends of the two fertilizer discharging devices 4 are respectively provided with a second rotating shaft 20. The second rotating shaft 20 is connected to the ground wheel 1 through a primary sprocket 3. The right side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com