Method for preparing polyolefin

A polyolefin and polyolefin catalyst technology, applied in the polymer field, can solve the problems of reducing catalyst activity, increasing the types of active sites, etc., and achieve the effects of increasing metal loading, non-toxic and easy to degrade, and shortening impregnation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The steps to prepare alkenes are as follows:

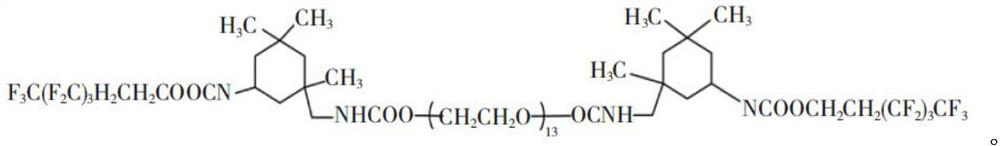

[0025] (1) Preparation of silica gel carrier: 5.0 g of carbon microspheres (10-40 μm in particle size range) are added to 200 ml of hydrochloric acid solution with a molar concentration of 1 mol / L and stirred evenly to obtain a hydrochloric acid solution containing carbon microspheres; under stirring, 1.25 Add 4 g of tetraethyl orthosilicate slowly in the hydrochloric acid solution of carbon-containing microspheres prepared in the preceding steps and continue to stir, then add 25 g of a mass concentration of 40% sodium silicate aqueous solution to obtain a silicon source solution; Add 2.5g template agent F4-PEG600-F4 and stir evenly to prepare hydrated silica gel, then transfer the obtained gel to a microwave reaction tank for thermal aging, microwave reaction at 90°C for 1.5h at a microwave power of 300W ; The resulting product is cooled and filtered, and the resulting solid is washed with ethanol / water to neutrality (test...

Embodiment 2

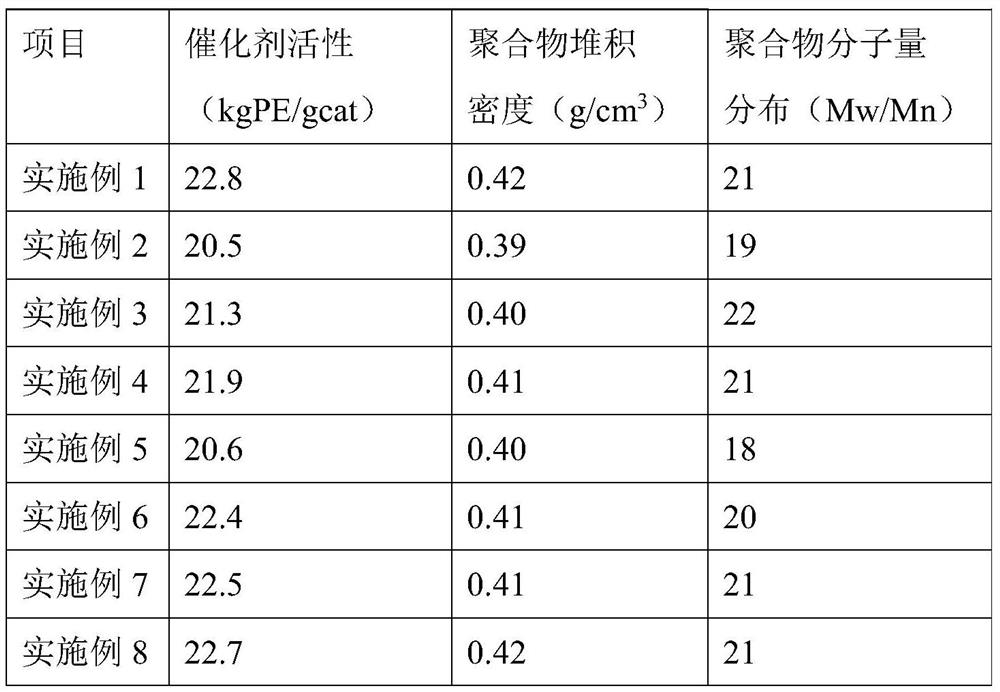

[0033] The preparation of silica gel carrier and catalyst is the same as in Example 1, and the reference example 1 for the preparation of polyolefin, except that ethylene is replaced by propylene in step (3), and other conditions are the same to obtain ethylene-propylene copolymer; catalyst activity 20.5kgPE / gcat, polymer bulk density 0.39g / cm 3 , the molecular weight distribution Mw / Mn of the polymer is 19, and the polymerization results are shown in Table 1.

Embodiment 3

[0035] The preparation of silica gel carrier and catalyst is the same as in Example 1, and the reference example 1 for the preparation of polyolefin, except that ethylene is replaced by 1-butene in step (3), and other conditions are the same to obtain ethylene-1-butene copolymerization material; catalyst activity 21.3kgPE / gcat, polymer bulk density 0.40g / cm 3 , the molecular weight distribution Mw / Mn of the polymer is 22, and the polymerization results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com