Co/BN catalyst for Fischer-Tropsch synthesis as well as preparation method and application of Co/BN catalyst

A Fischer-Tropsch synthesis and catalyst technology, which is used in the preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, chemical instruments and methods, etc. It can solve problems such as affecting the utilization efficiency of carbon atoms, low dispersion of active metals, and low catalyst activity. , to achieve the effects of low methane selectivity, high metal loading, and high CO conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

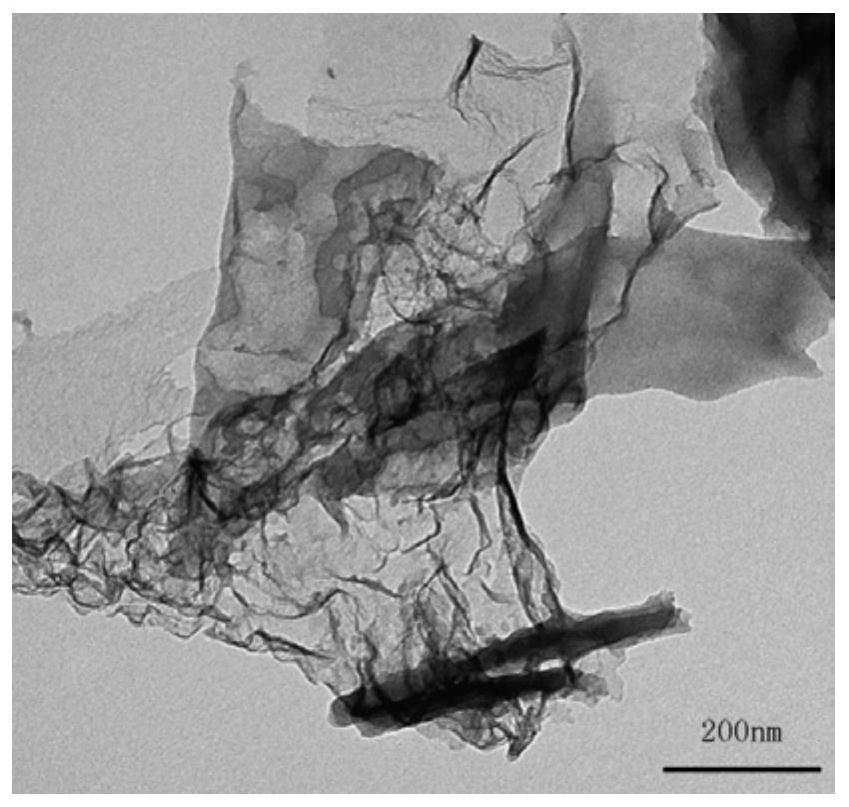

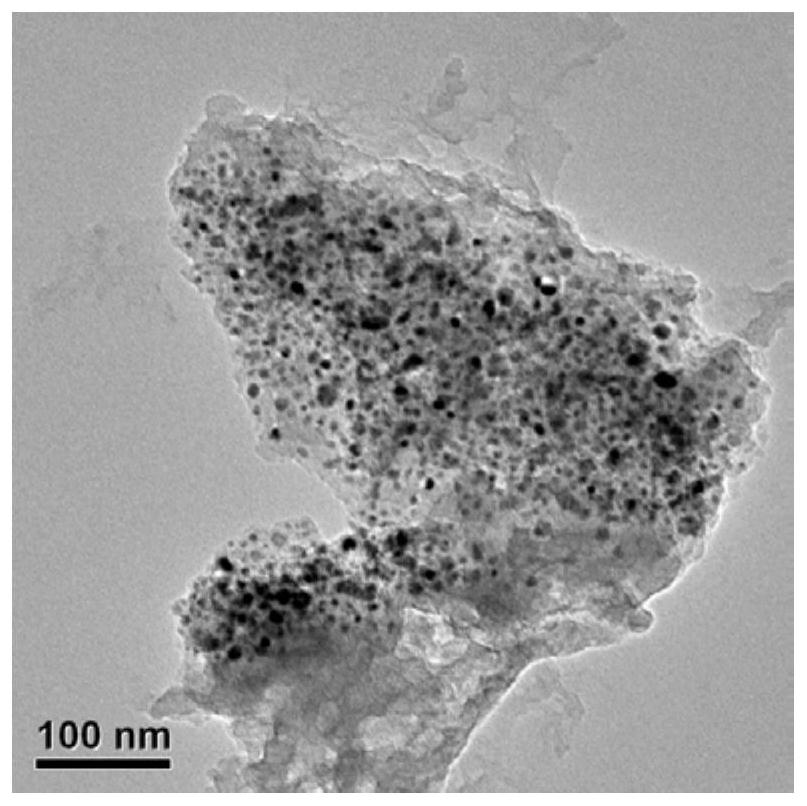

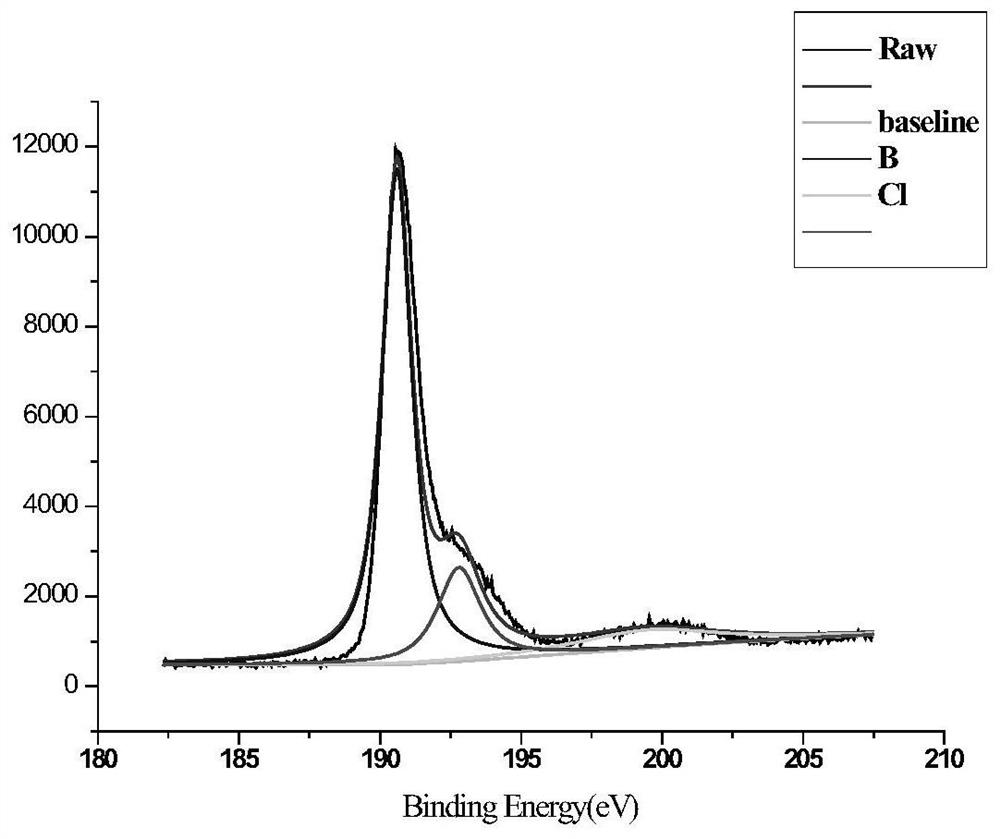

Embodiment 1

[0032] Weigh Co(NO 3 ) 3 ·6H 2 O 118g, prepared with deionized water into a mixed salt solution with a total concentration of 0.9mol / L, adding 180g of boron nitride with two-dimensional nanosheets in the prepared nitrate solution, stirring continuously for 2h, putting in Blast drying oven, the reaction temperature is 120 ℃, and the reaction time is 10h. Then, it was left to stand for aging for 5 hours, filtered with suction, and the precipitate was repeatedly washed with deionized water. 50 mL of deionized water was added to the filter cake, followed by sonication for 10 minutes, and beating. Then, it was dried at 120°C for 10 hours, and finally calcined at 500°C for 9 hours, cooled, pressed, and crushed, and 60-80 mesh was selected as the fixed-bed Fischer-Tropsch synthesis catalyst. At 0.3MPa, 1000h -1 , at 350 ℃ for 30 hours with hydrogen reduction, and then at 180 ℃, 1.5MPa, 2000h -1 , raw gas H 2 The Fischer-Tropsch synthesis performance of the catalyst was evaluat...

Embodiment 2

[0034] Weigh Co(NO 3 ) 3 ·6H 2O 118g, prepare a mixed salt solution with a total concentration of 1.5mol / L with deionized water, add 95g of boron nitride with two-dimensional nanosheets in the prepared mixed salt solution, stir continuously for 2h, put in Blast drying oven, the reaction temperature is 90 ℃, and the reaction time is 8h. Then, it was left to stand for aging for 5 hours, filtered with suction, and the precipitate was repeatedly washed with deionized water. 50 mL of deionized water was added to the filter cake, followed by sonication for 10 minutes, and beating. The above two kinds of slurries were mixed, the slurry was dried at 120°C for 20 hours, and finally calcined at 400°C for 5 hours, cooled, pressed, formed and broken, and 60-80 mesh was selected as the fixed-bed Fischer-Tropsch synthesis catalyst. At 0.2MPa, 2000h -1 , 450 ℃ for 20 hours with hydrogen reduction, and then at 190 ℃, 2.0MPa, 1000h -1 , raw gas H 2 The Fischer-Tropsch synthesis performa...

Embodiment 3

[0036] Weigh Co(NO 3 ) 3 ·6H 2 O 64g, prepared with deionized water into a nitrate solution with a total concentration of 1.0mol / L, adding 70g of boron nitride with two-dimensional nanosheets in the prepared salt solution, stirring continuously for 2h, and putting it into a drum Air drying oven, the temperature is 100 ℃, and the drying time is 5h. The second weighing of Co(NO 3 ) 3 ·6H 2 O 64g, prepared into a nitrate solution with a total concentration of 1.0mol / L with deionized water, added the above dry material to the prepared salt solution, stirred continuously for 2h, put it into a blast drying oven, the drying temperature was 120 ℃, dried The time is 10h. Then, it was left to stand for aging for 5 hours, filtered with suction, and the precipitate was repeatedly washed with deionized water. 50 mL of deionized water was added to the filter cake, followed by sonication for 10 minutes, and beating. Finally, it was calcined at 500°C for 9 hours, cooled, pressed into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com