A kind of preparation method of sulfurized hydrotreating catalyst

A technology for hydrorefining and catalyst, applied in the field of catalysis, can solve the problems of complex catalyst preparation process, high toxicity of vulcanizing agent, poor storage stability, etc., and achieve the effect of high utilization rate of active metal, excellent catalyst performance and stable property.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the sulfurized hydrofining catalyst of the present invention is to impregnate the required catalyst carrier with an impregnating solution, the impregnating solution contains ammonium molybdate and / or ammonium tungstate, nickel salt and / or cobalt salt, and simultaneously contains vulcanizing agent, organic complex agent and co-solvent; after the in-situ crystallization reaction in a closed container, drying and heat treatment are carried out to obtain the final sulfurized hydrofining catalyst.

[0042] In the preparation process of the sulfide-type hydrofining catalyst of the present invention, the impregnation method is a conventional method in the field, and the required metal salt, vulcanizing agent, organic complexing agent and co-solvent are mixed, stirred and dissolved, and prepared into a clarified product with a suitable pH value. solution, and then impregnated by means of saturated impregnation or excess impregnation.

[0043] The speci...

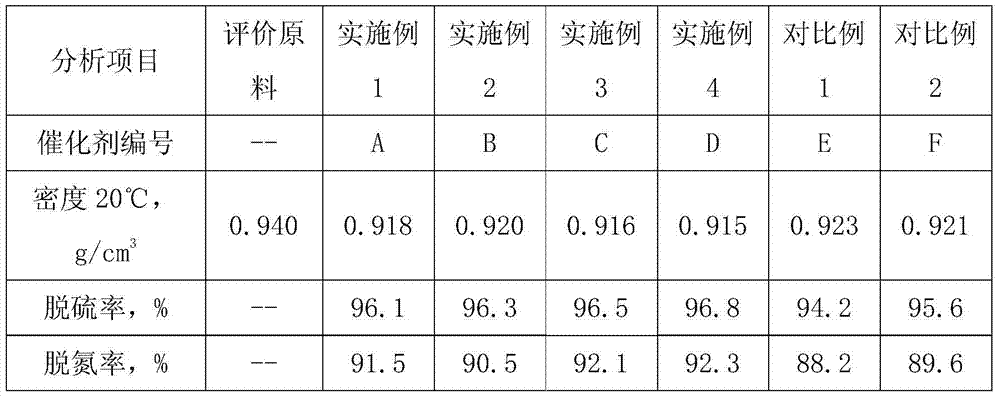

Embodiment 1

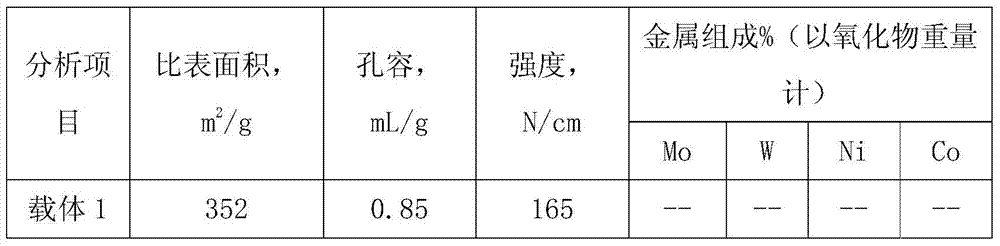

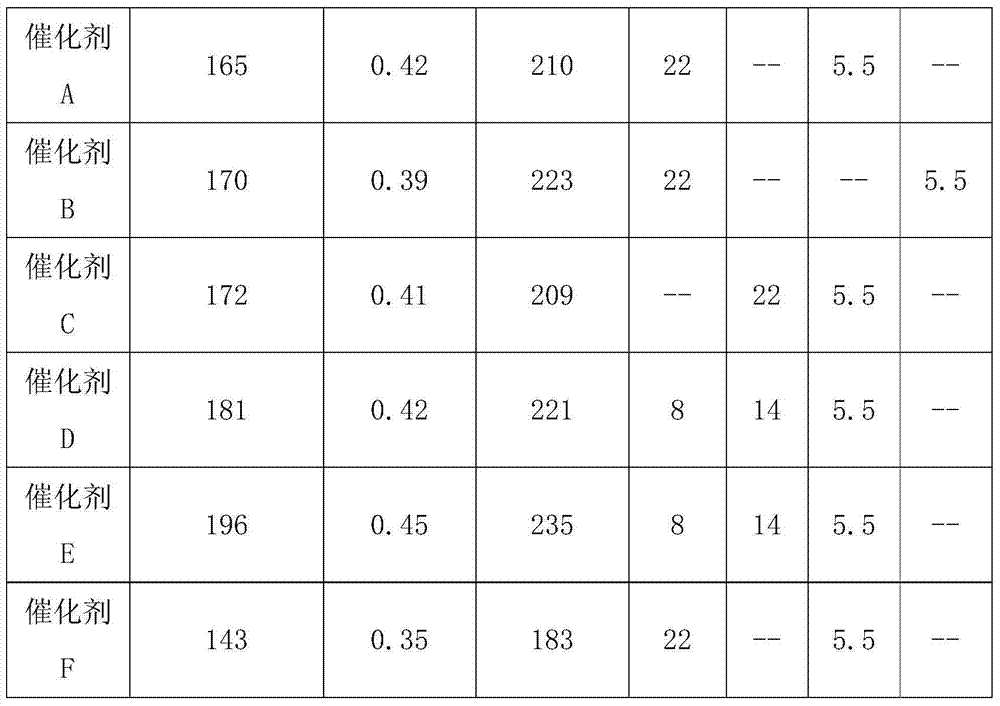

[0048] The preparation of embodiment 1 sulfurized catalyst A

[0049] Take by weighing pseudo-boehmite (Shandong Aluminum Co., Ltd. produces macroporous pseudo-boehmite, which is 72% by weight on a dry basis) 1000g, 20g of scallop powder, 30g of citric acid, 800ml of dilute nitric acid (weight concentration 3%) , kneaded in a kneader for 30 minutes, and then extruded into 1.5mm clover strips on an extruder, dried and calcined at 550° C. for 3 hours to obtain the desired catalyst carrier 1 .

[0050] Dissolve basic nickel carbonate, ammonium molybdate and ethylenediaminetetraacetic acid in ammonia water to obtain a transparent solution, add ethanolamine, ethylenediamine and dithioacetamide in turn to form a clear solution, and the amount of active components in the solution is according to Table 1 The data determined that the molar ratio of dithioacetamide to active metal was 1.6:1. The mixed solution was sprayed and impregnated with carrier 1, in-situ crystallized in a closed...

Embodiment 2

[0051] The preparation of embodiment 2 sulfurized catalyst B

[0052] Dissolve cobalt nitrate, ammonium molybdate and citric acid in water, stir and heat to obtain a transparent solution, add ethylenediamine, aminotrimethylene phosphonic acid and ammonium thiosulfate in turn, mix and stir to form a clear solution, and the amount of active components in the solution is based on The data in Table 1 confirm that the molar ratio of ammonium thiosulfate to active metal is 2.5:1. The mixed solution was sprayed and impregnated with carrier 1, in-situ crystallized in a closed reactor at 75°C for 3 hours, and then vacuum-dried at 220°C for 4 hours to obtain catalyst B. The main physical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com