Method for detecting total foam protein component and content of beer barley and malt

A barley and malt technology, used in the preparation of test samples, measurement of color/spectral properties, biological testing, etc., can solve problems such as inability to occupy a place and low quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

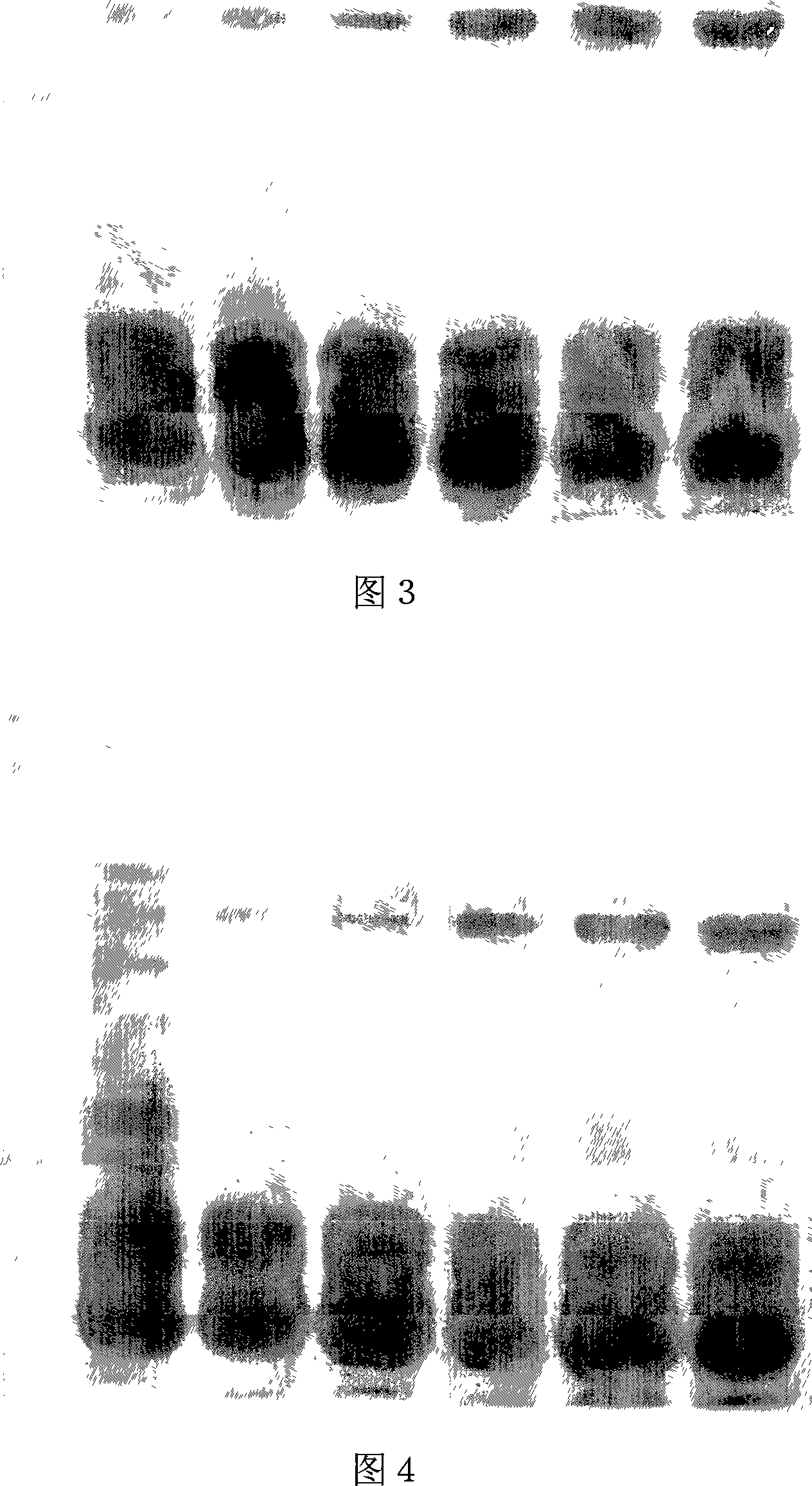

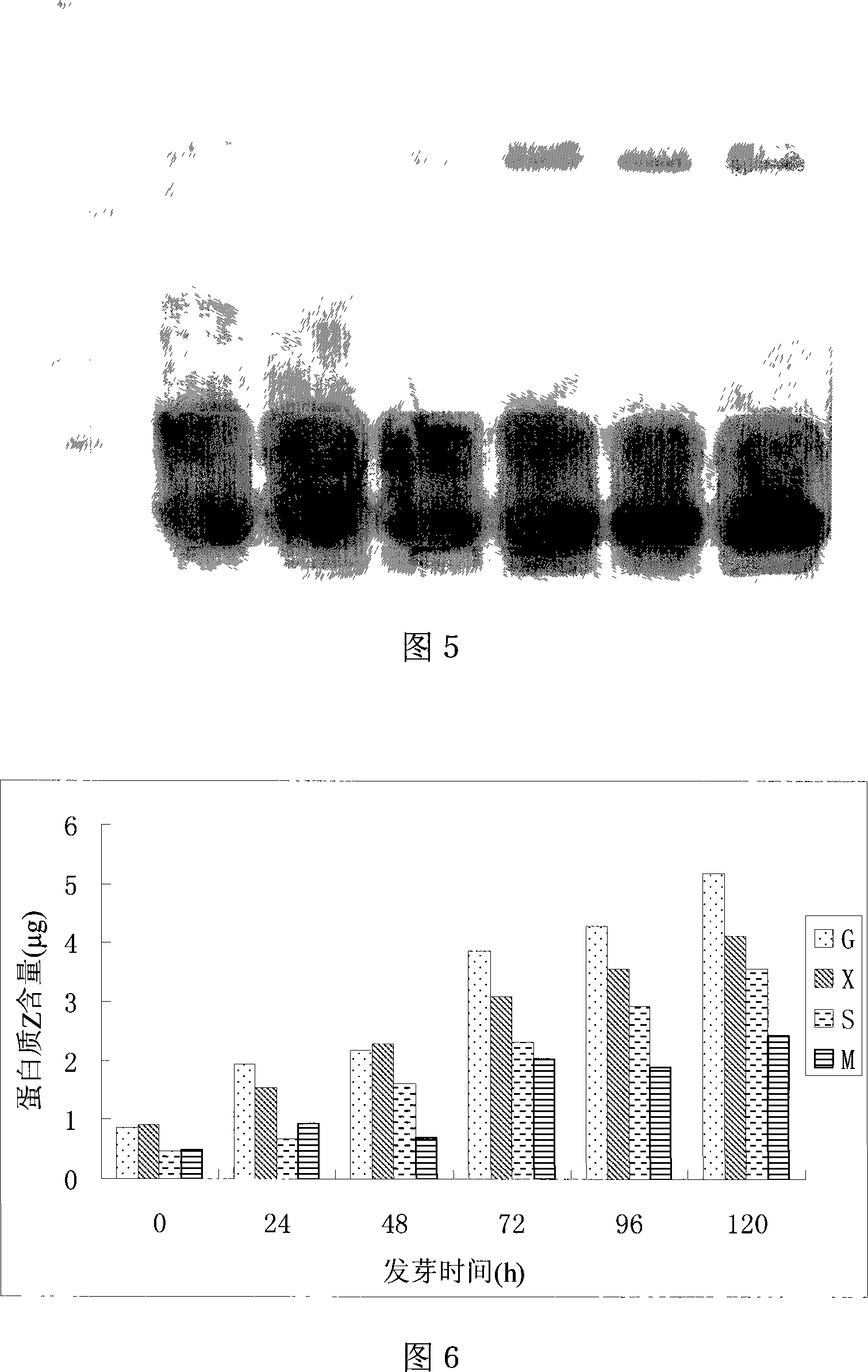

[0041] Four varieties of barley were germinated under the same conditions, namely Schooner (Australia), Gairdner (Canada), Ganpi No. 2 (Xinjiang), and Ganpi No. 3 (Inner Mongolia).

[0042] Germination conditions: pH 6.8 for soaking and spraying water, 16°C, dark room, ventilation.

[0043] Germination time: Soak wheat for 24 hours, germinate for 96 hours, a total of 120 hours.

[0044] Sampling is taken every 24 hours, and the original wheat sample is recorded as 0 hour of germination. There are a total of 24 samples, which are recorded as Schooner S0~S120, Gardner G0~G120, Gan Beer No. 2 X0~X120, Gan Beer No. 3 M0~M120.

[0045] Extraction buffer pH7.5, Tris-Cl50mmol L -1 , NaCl10mmol·L -1 , DTT1mmol-L -1 , EDTA·2Na 1mmol·L -1 , and the balance is water.

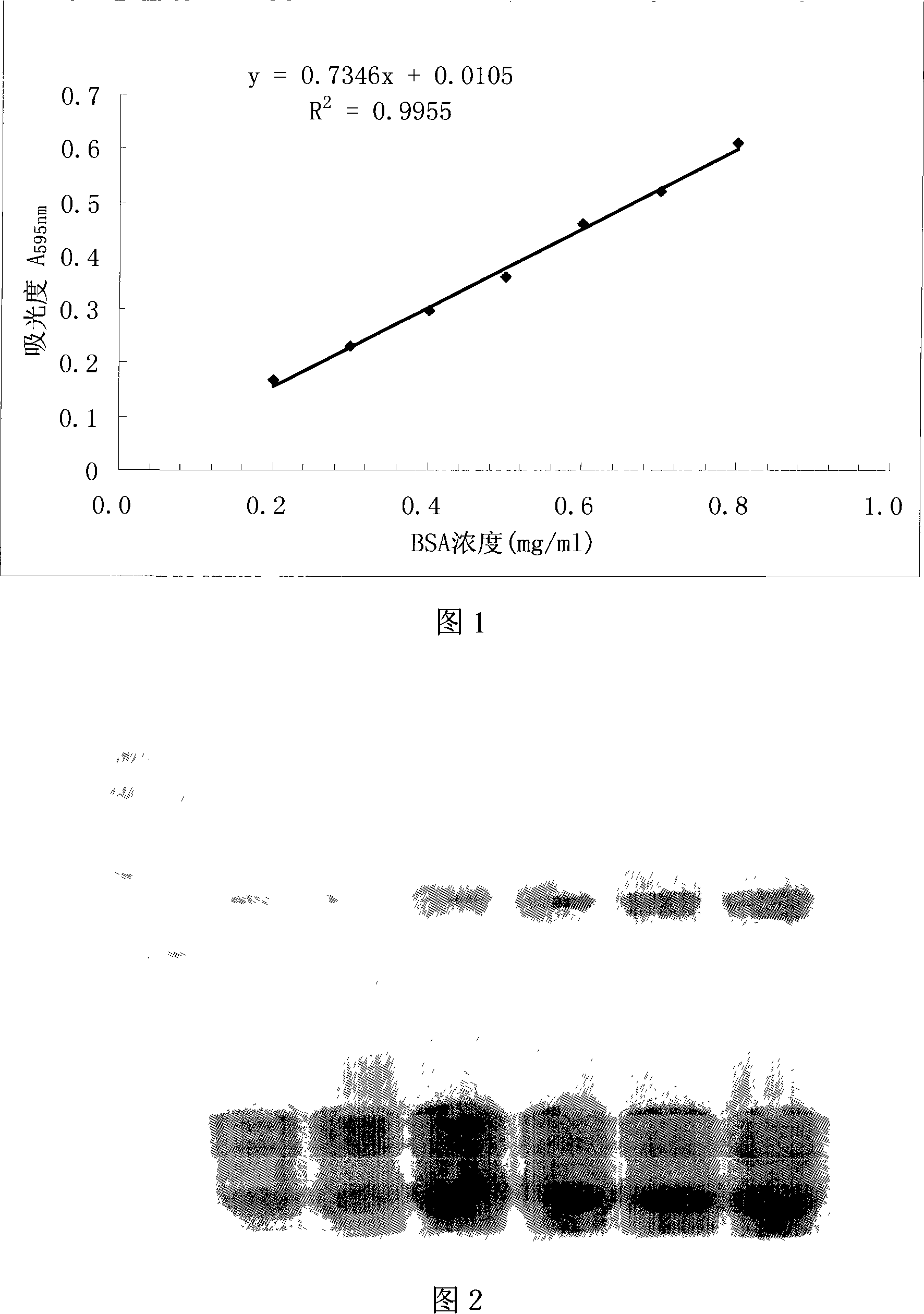

[0046] Crush the above 24 samples respectively, weigh 1g each (the absolute dry weight after deducting water), put it in a centrifuge tube, add 3ml of 4°C extraction buffer, shake well, and extract at 4°C for 1 hour,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com