A process for improving foam tendency in waste oil refining process

A technology of waste engine oil and process, which is applied in the field of waste engine oil refining process, can solve the problems such as inability to achieve foam tendency, achieve outstanding economic benefits, realize industrialization, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

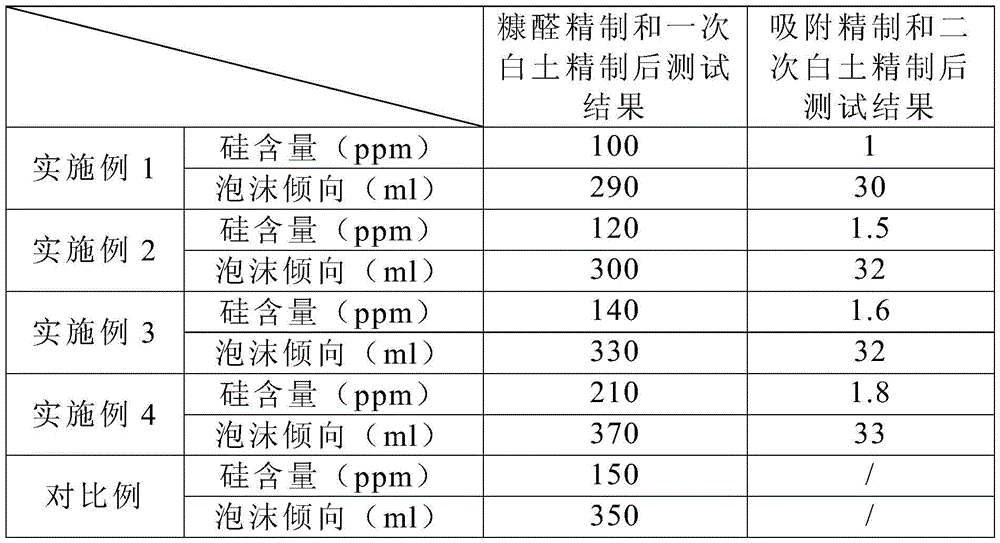

Embodiment 1

[0024] After the waste engine oil is distilled and cut, the kinematic viscosity at 40°C is 30mm 2 / s, an acid value of 0.3 mgKOH / g, and a crude oil with a silicon content of 180 ppm is used as the raw oil of this embodiment. In the reactor, feedstock oil at a temperature of 65°C and furfural at a temperature of 95°C were added at a mass ratio of 1:3, and fully contacted for 2 hours to obtain oil product I. Then the separated oil I was refined with white clay at 135°C for 120 minutes, the amount of white clay was 3% of the volume of oil I, the decolorizing power of white clay was 160, the particle size was 230 mesh, and the free acid was 0.15. After refining, use a plate and frame filter to filter to obtain oil product II. Then the oil product II obtained by filtration is passed through the adsorbent activated carbon to complete the adsorption and refining to obtain the oil product III. Finally, the obtained oil product III was further refined with clay at 135° C., the refini...

Embodiment 2

[0026] After the waste engine oil is distilled and cut, the kinematic viscosity at 40°C is 32mm 2 / s, the acid value is 0.3mgKOH / g, and the crude oil with a silicon content of 200ppm is used as the raw material oil of this embodiment. In the reactor, feedstock oil at a temperature of 65°C and furfural at a temperature of 95°C were added at a mass ratio of 1:3, and fully contacted for 2 hours to obtain oil product I. Then the separated oil I was refined with white clay at 135°C for 120 minutes, the amount of white clay was 3% of the volume of oil I, the decolorizing power of white clay was 180, the particle size was 250 mesh, and the free acid was 0.1. After refining, use a plate and frame filter to filter to obtain oil product II. Then the oil product II obtained by filtration is passed through the adsorbent activated carbon to complete the adsorption and refining to obtain the oil product III. Finally, the obtained oil product III was refined with clay again at 135° C., the...

Embodiment 3

[0028] After the waste engine oil is distilled and cut, the kinematic viscosity at 40°C is 33mm 2 / s, the acid value is 0.2mgKOH / g, and the crude oil with a silicon content of 235ppm is used as the raw material oil of this embodiment. In the reactor, feedstock oil at a temperature of 65°C and furfural at a temperature of 95°C were added at a mass ratio of 1:3, and fully contacted for 2 hours to obtain oil product I. Then the separated oil I was refined with white clay at 135°C for 120 minutes, the amount of white clay was 3% of the volume of oil I, the decolorizing power of white clay was 200, the particle size was 280 mesh, and the free acid was 0.1. After refining, use a plate and frame filter to filter to obtain oil product II. Then the oil product II obtained by filtration is passed through the adsorbent activated carbon to complete the adsorption and refining to obtain the oil product III. Finally, the obtained oil product III was refined with clay again at 135° C., the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com