High performance liquid chromatography determination method for identifying starch syrup adulteration in honey

A technology of high performance liquid chromatography and starch syrup, which is applied in the field of qualitative determination of starch syrup adulteration in honey by using high performance liquid chromatography, and achieves the effect of simple sample pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

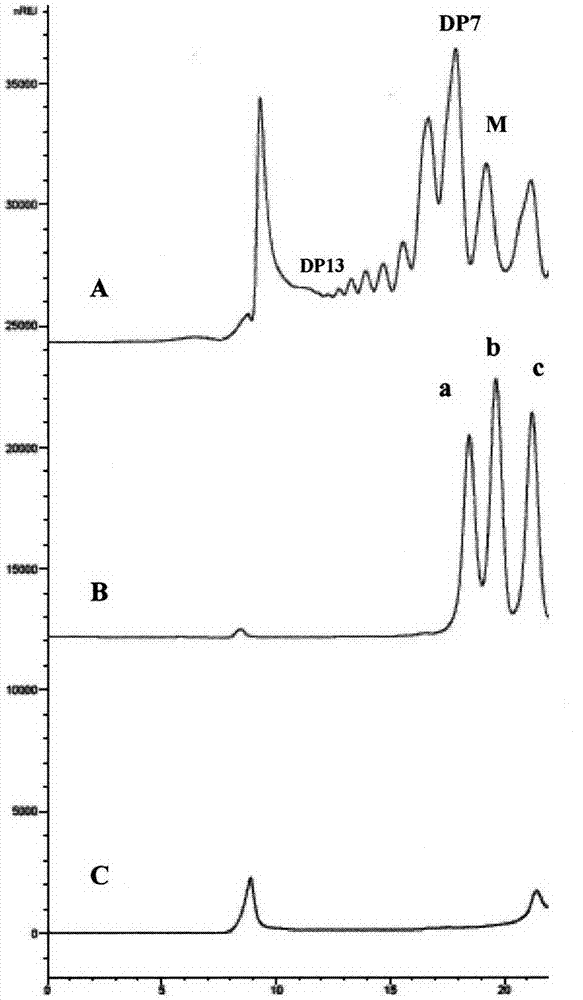

Examples

Embodiment 1

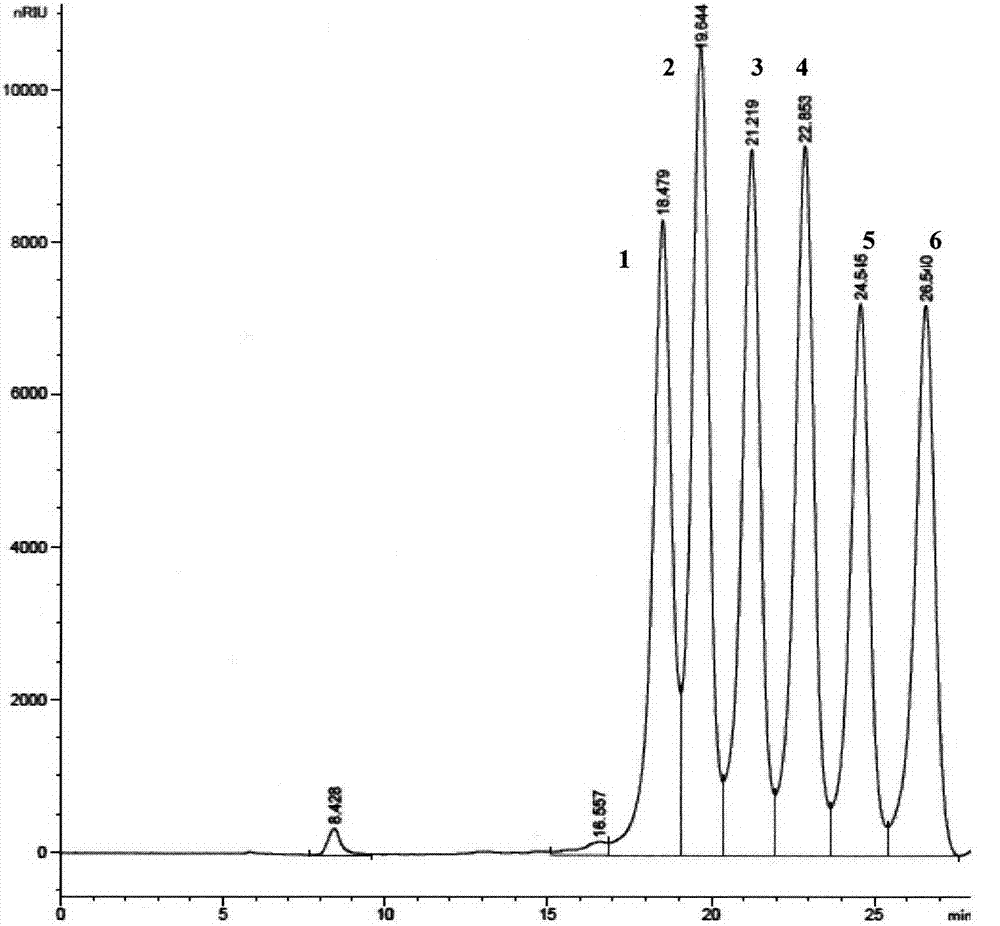

[0030] 1. Preparation of maltooligosaccharide standard mixture: Weigh 10.0 mg each of chromatographically pure maltose, maltotriose, maltotetraose, maltopentaose, maltohexaose, and maltoheptaose, respectively, and dissolve them in distilled water to 10 mL. Prepare a stock solution with a concentration of 1.0 mg / mL in a brown bottle.

[0031] details as follows:

[0032] Table 1 Preparation of maltooligosaccharide standard mixture

[0033]

[0034] 2. Sample pretreatment method: weigh 1g of sample, accurate to 0.001g. Dissolve in 4mL of distilled water, transfer the sample solution to OASIS HLB (6mL, 200mg) small column, and after the sample liquid flows out completely, then use 6mL of 30% acetonitrile aqueous solution to elute, collect the eluate, and wash the eluate with 0.22 μm membrane filtration to be determined. to be tested.

[0035] 3. Liquid chromatography conditions:

[0036] a) Chromatographic column: Benson BP-200Ag+ (7.8mm I.D×300mm);

[0037] b) Column t...

Embodiment 2

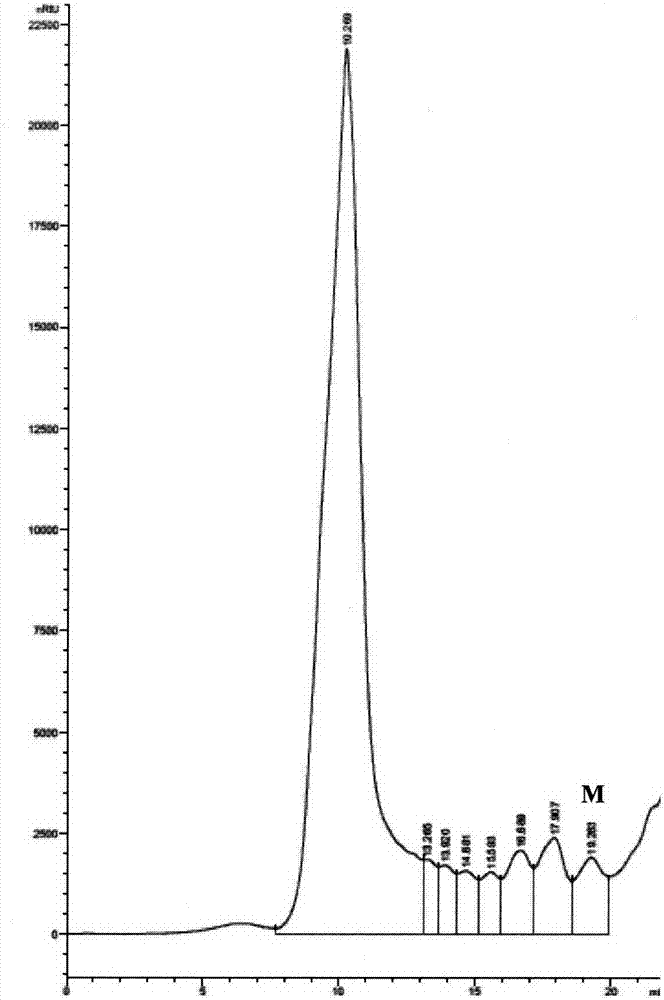

[0044] 1. Preparation of maltooligosaccharide standard mixture: Weigh 10.0 mg each of chromatographically pure maltose, maltotriose, maltotetraose, maltopentaose, maltohexaose, and maltoheptaose, respectively, and dissolve them in water to 10 mL. Make a stock solution with a concentration of 1.0 mg / mL in a brown bottle.

[0045] details as follows:

[0046] Table 1 Preparation of maltooligosaccharide standard mixture

[0047]

[0048] 2. Sample pretreatment method: weigh 1g of sample, accurate to 0.001g. Dissolved in 2mL of water, the resulting solution was filtered through a 0.45μm membrane filter, and tested.

[0049] 3. Liquid chromatography conditions:

[0050] a) Chromatographic column: Mitsubishi MCI GEL CK04SS (10mm I.D×200mm);

[0051] b) Column temperature: 100°C;

[0052] c) mobile phase: distilled water;

[0053] d) Flow rate: 1mL / min;

[0054] e) Injection volume: 10uL;

[0055] f) Detector: differential detector (RI);

[0056] g) Data collection time:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com