Mass flow rate and density measuring method for technological matter

A mass flow and logistics technology, applied in the direction of mass flow measurement device, measurement flow/mass flow, indirect mass flowmeter, etc., can solve the problem of not solving the problem of measuring mass flow, and achieve the effect of reducing permanent pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

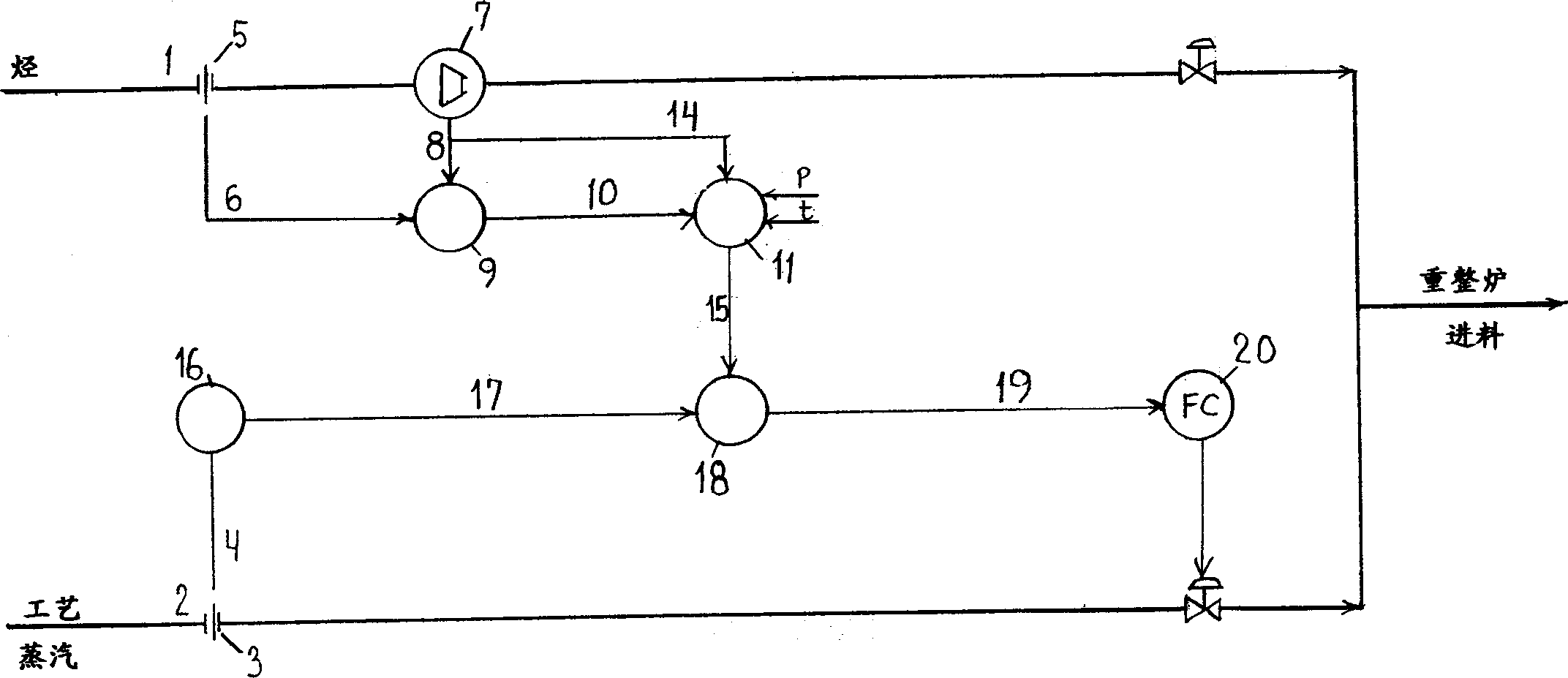

[0039] If the process feed is natural gas or naphtha, the possible feed flow rates for natural gas or naphtha are

[0040] natural gas naphtha

[0041] Volume flow, Nm 3 / h 31430 8698

[0042] Mass flow rate, kg / h 22735 21857

[0043] From these figures it can be seen that the volumetric flow controller maintains 31430Nm 3 / h of natural gas, can not maintain 8698Nm 3 / h of naphtha, while the mass flow controller maintains 22735kg / h of natural gas, which also maintains the flow of naphtha.

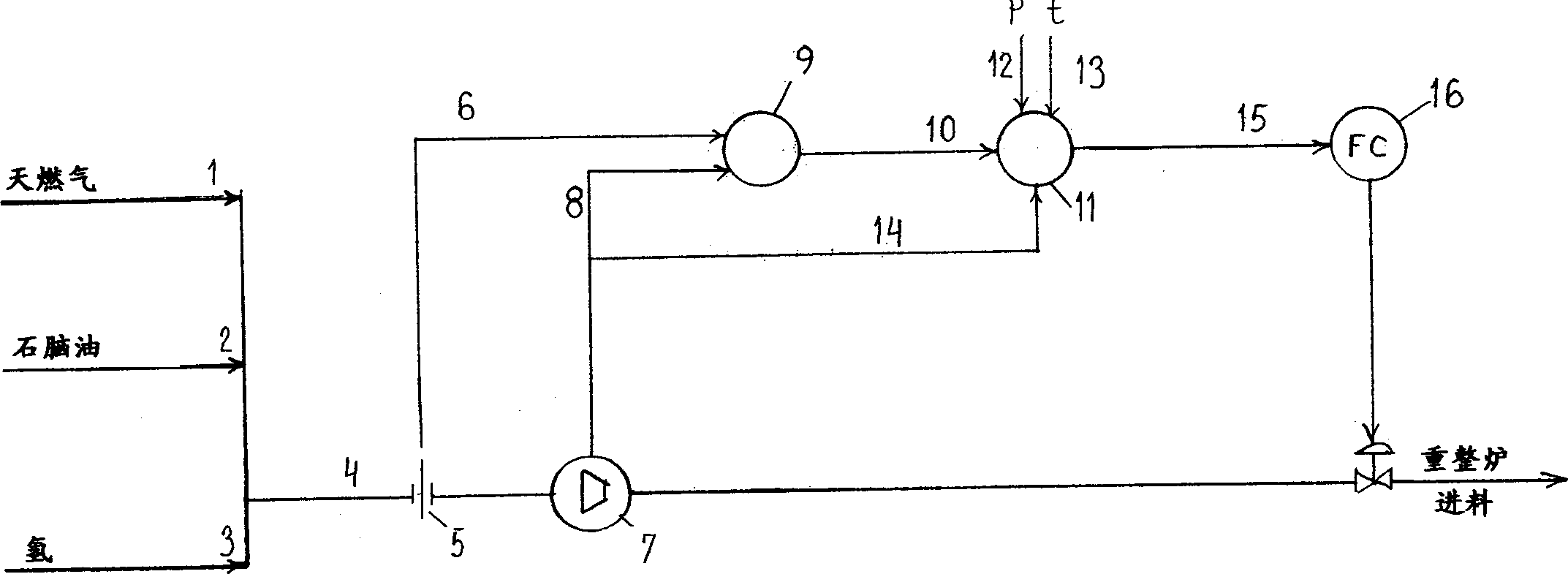

Embodiment 2

[0045] A feed to the reformer consists of 21468kg / h of heavy naphtha and 389.3kg / h of hydrogen with molecular weights of 109.36 and 2.03 respectively, or 4400Nm 3 / h naphtha and 4298Nm 3 / h of hydrogen.

[0046] If the hydrogen flow is increased by 30%, the molecular weight of the process stream changes from 56.32 to 49.32.

[0047] A flow controller accepting a signal from a differential pressure flow element will vary the flow to 9295Nm 3 / h, which is equivalent to a signal equal to the original signal, i.e. keeping ρv 2 .

[0048] In this process, the mass flow rate of naphtha was reduced by 7%. The flow controller receiving the signal from the mass flow measurement will maintain a total mass flow of 21857.3 kg / h which is now comparable to naphtha at 21357 kg / h, ie only a 0.5% reduction.

Embodiment 3

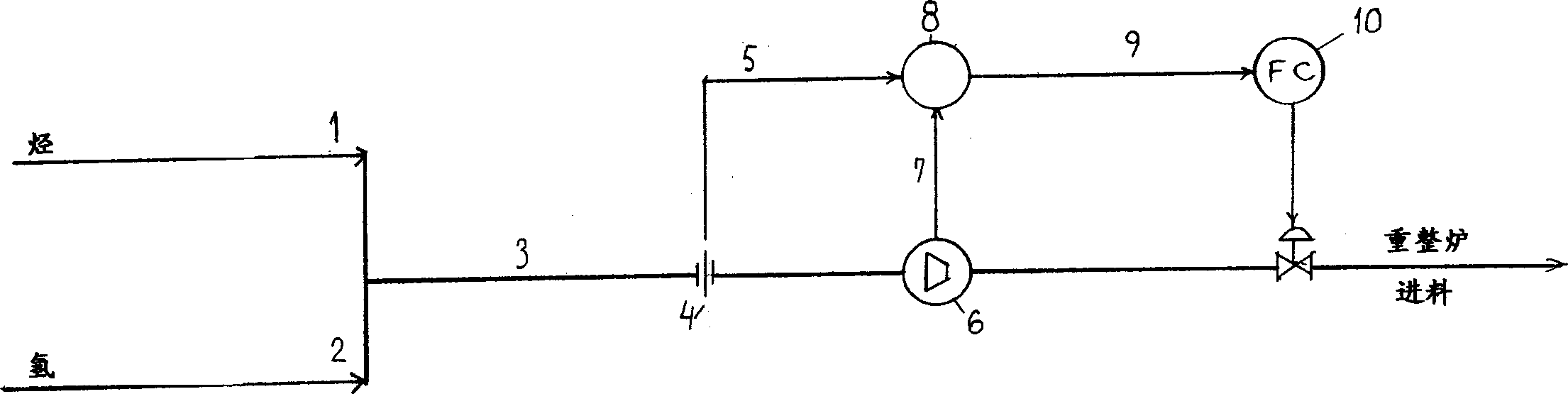

[0050] One embodiment of the application of the present invention is the control of reformer mass flow rate, such as figure 1 shown.

[0051] The hydrocarbon feed to the reformer is a mixture of hydrocarbon 1 and hydrogen 2 . Both the hydrocarbon composition and the ratio of hydrocarbon flow to hydrogen flow will be different from one operating condition to another. The combined feed stream 3 is first measured in the flow orifice 4, which produces a mass flow rate in kg / h proportional to the product and in proportion to the actual volume flow m 3 / h signal 5. The downstream process stream then flows through a vortex element 6 which produces a flow proportional to the actual volume flow m 3 / h signal 7. Signals 5 and 6 go to calculating relay 8 which divides signal 5 by signal 7 to produce signal 9, the mass flow in kg / h. Signal 9 is used for flow controller 10 which controls the position of the flow valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com