Technological process for preparing active powder concrete by using iron tailing

A technology of active powder and process method, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. It can solve the problems of consuming natural resources such as quartz sand or river sand, small sales radius, and transportation distance restrictions. Achieve the effect of improving comprehensive utilization rate, protecting ecological environment and reducing raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

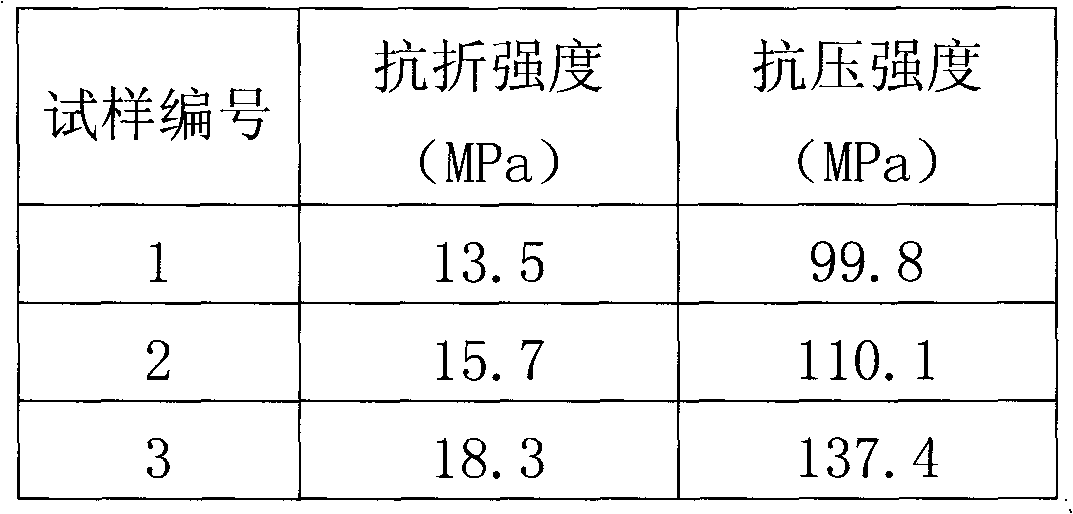

Embodiment 1

[0034] Use SiO 2 Iron tailings with a content of 69%, sieve 0.16mm~1.25mm iron tailings as iron tailings fine aggregate, and grind the remaining tailings to a specific surface area of 600m 2 / kg of activated iron tailings is used as the active powder component, and 42.5 ordinary Portland cement, specific surface area 450m 2 / kg of Grade II fly ash, specific surface area 20000m 2 / kg of silica fume, naphthalene series UNF-5 type superplasticizer is mixed, after the raw materials are selected, the components of the reactive powder concrete material are prepared according to the following weight (%):

[0035] 42.5 ordinary Portland cement 25;

[0036] Specific surface area 450m 2 / kg of Grade II fly ash 7.5;

[0037] Activated iron tailings 6.5;

[0038] Specific surface area 20000m 2 / kg of silica fume 5;

[0039] Iron tailings fine aggregate 44.2;

[0040] Naphthalene UNF-5 type superplasticizer 0.8;

[0041] Water 11.

[0042] After the components of the reactive powder concrete material...

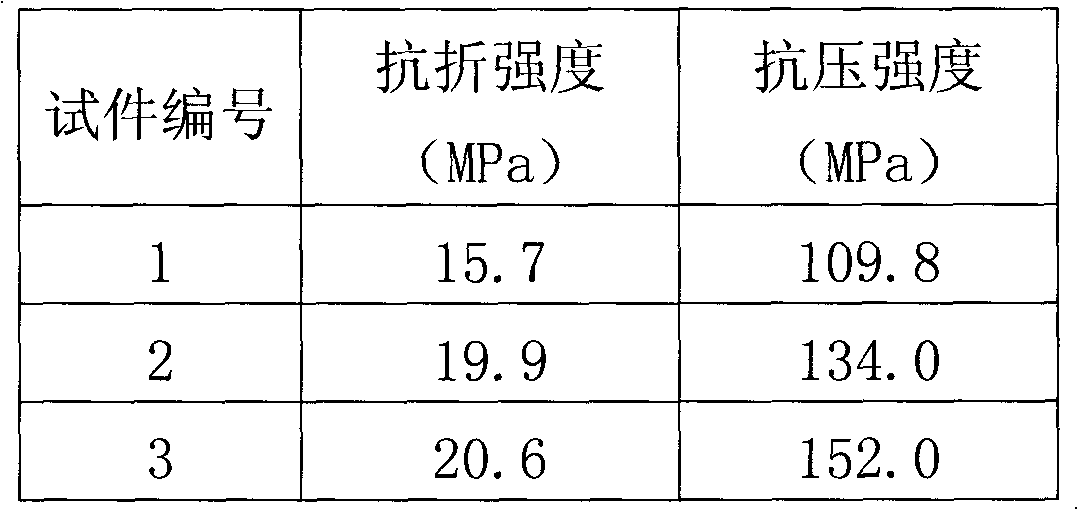

Embodiment 2

[0051] Use SiO 2 Iron tailings with a content of 69%, sieve 0.16mm~1.25mm iron tailings as iron tailings fine aggregate, and grind the remaining tailings to a specific surface area of 600m 2 / kg of activated iron tailings is used as the active powder component, and it has a specific surface area of 450m with 52.5 ordinary Portland cement. 2 / kg of blast furnace slag, specific surface area 20000m 2 / kg of silica fume, naphthalene-based DNF type superplasticizer is mixed, and the components of the reactive powder concrete material are prepared according to the following weight (%) after the raw materials are selected:

[0052] 52.5 ordinary Portland cement 24

[0053] Specific surface area 450m 2 / kg of blast furnace slag 7.2;

[0054] Activated iron tailings 6;

[0055] Specific surface area 20000m 2 / kg of silica fume 4.8;

[0056] Iron tailings fine aggregate 47.15;

[0057] Naphthalene DNF type superplasticizer 0.85;

[0058] Water 10.

[0059] After the components of the reactive po...

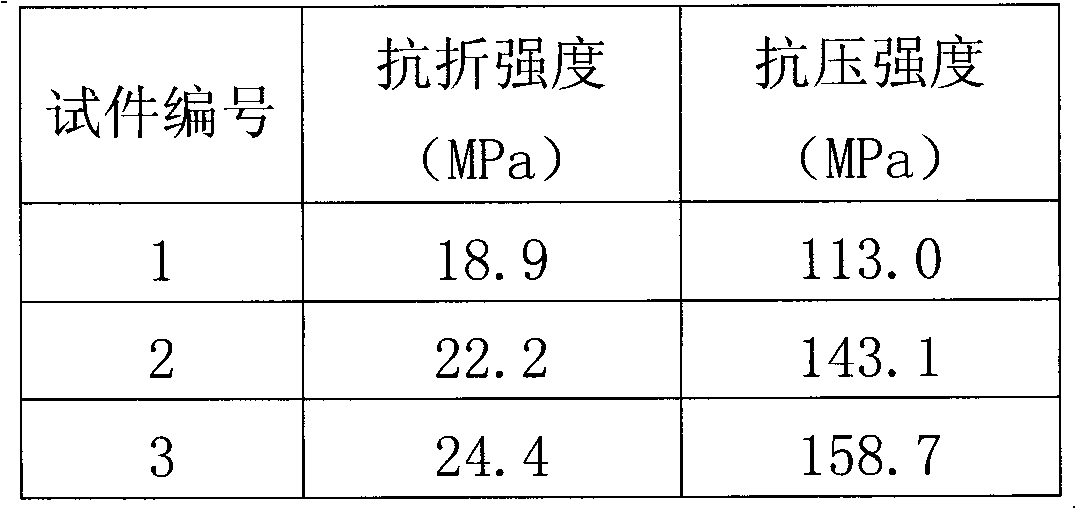

Embodiment 3

[0068] Use SiO 2 72% of the iron tailings, the iron tailings of 0.08mm~1.25mm are screened as the iron tailings fine aggregate, and the remaining tailings are ground to a specific surface area of 580m 2 / kg of activated iron tailings is used as the active powder component, and 42.5 ordinary Portland cement, specific surface area 450m 2 / kg of Grade II fly ash, specific surface area 20000m 2 / kg of silica fume, 13mm copper-plated steel fiber special for reactive powder concrete, naphthalene UNF-5 type superplasticizer mixed, after the raw materials are selected, the components of the reactive powder concrete material are prepared according to the following weight (%):

[0069] 42.5 ordinary Portland cement 23.7;

[0070] Specific surface area 450m 2 / kg of Grade II fly ash 7.1;

[0071] Activated iron tailings 5.9;

[0072] Specific surface area 20000m 2 / kg of silica fume 4.7;

[0073] Iron tailings fine aggregate 41.55;

[0074] Copper-plated steel fiber special for 13mm reactive powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com