Method for reusing common steel slag

A common steel and steel slag technology, which is applied in recycling technology, chemical instruments and methods, and filter screens, can solve the problems of insufficient utilization of resources and low metal recovery rate of common steel and steel slag processing lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

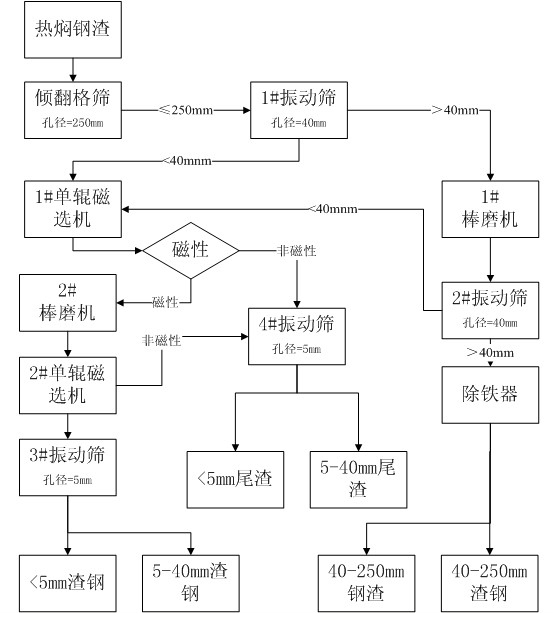

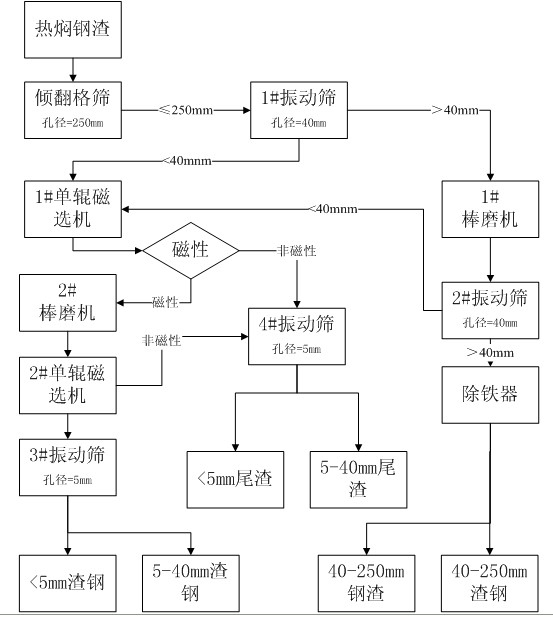

Image

Examples

Embodiment

[0036] Example: This embodiment is an embodiment of a common carbon steel slag processing production line with an annual processing capacity of 600,000 tons in the carbon steel slag division of the Taiyuan Iron and Steel Processing Plant in January 2011, and the operation effect is good.

[0037] 1. Stewed slag and dried

[0038] ⑴Slag stewing: transport the red-hot ordinary steel slag out of the furnace to the hot pouring field, and preliminarily crush the large steel slag with a particle size greater than 2 meters, and then put the ordinary steel slag into it with a length of 7 meters and a width of 7 meters. , the effective depth is 5 meters in the hot pool, wait for 30 minutes for soaking; cover the lid and use the spray device in the cover to continuously and evenly draw water on the steel slag. The spray device adopts a spiral nozzle, which is required The distribution is even and can cover the entire slag surface, the water flow rate is 20 tons / hour, and the water ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com