Automatic slag feeding machine for continuous casting crystallizer

The technology of automatic slag feeder and continuous casting mold is applied in the field of automatic slag feeder, which can solve the problems of high crushing rate of pipelines and mold slag, inability to adjust the inclination angle of feeding speed, easy wear of elbows and pipelines, etc., and achieves compact structure. , Large installation space, good uniformity of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

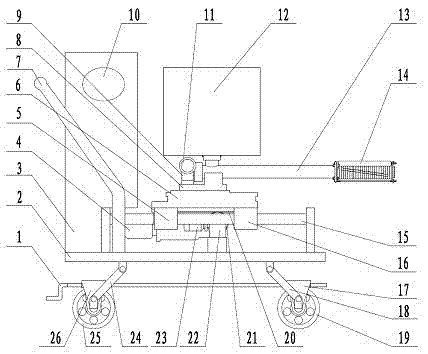

[0041] An automatic slag adding machine for continuous casting crystallizer. The slag adding machine includes a lifting frame, a slag adding system and a control system; the slag adding system is installed in the middle and front of the lifting frame, and the control system is installed in the rear of the lifting frame.

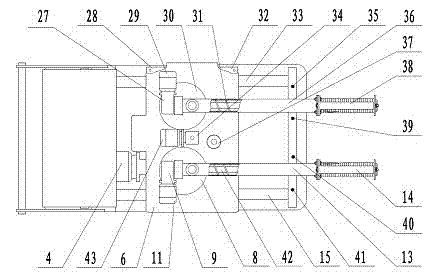

[0042] The structure of the lifting frame is as follows figure 1 and figure 2 Shown: lift vehicle frame comprises vehicle frame body 2, elevating mechanism and handrail 7; There are a first travel switch 41 , a second travel switch 40 , a third travel switch 39 and a fourth travel switch 35 .

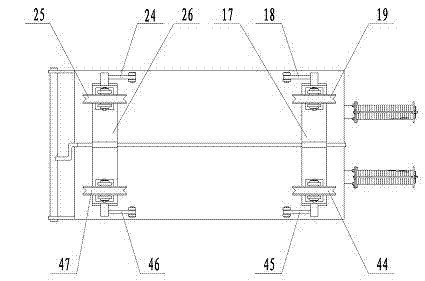

[0043] The structure of the lifting mechanism is as figure 1 and image 3 Shown: one end of the first connecting rod 18 and the second connecting rod 45 are symmetrically hinged on both sides of the centerline of the front part of the lower plane of the vehicle frame, and the other end of the first connecting rod 18 and the second connecting rod 45 is hinged on th...

Embodiment 2

[0058] An automatic slag adding machine for continuous casting crystallizer. Among them: the angle between the line connecting the first travel switch 41 and the axis of the swing output shaft of the first feed pipe 13 and the axis of the first guide rail 15 is 15-30°, and the second travel switch 40 and the first feed pipe 13 swing The angle between the line connecting the output shaft axis and the axis of the first guide rail 15 is 1~2°; Angle is 15 ~ 30 ° The angle between the connecting line of the third travel switch 39 and the axis of the second feed pipe 36 swing output shaft and the axis of the second guide rail 33 is 1 ~ 2 °; the number of gap rings 52 is 20 ~ 25.

[0059] All the other are with embodiment 1.

Embodiment 3

[0061] An automatic slag adding machine for continuous casting crystallizer. Among them: the angle between the line connecting the first travel switch 41 and the axis of the swing output shaft of the first feed pipe 13 and the axis of the first guide rail 15 is 30-45°, and the second travel switch 40 and the first feed pipe 13 swing The angle between the line connecting the output shaft axis and the axis of the first guide rail 15 is 2~3°; Angle is 30 ~ 45 ° The angle between the connecting line of the third travel switch 39 and the axis of the second feed pipe 36 swing output shaft and the axis of the second guide rail 33 is 2 ~ 3 °; the number of gap rings 52 is 25 ~ 30.

[0062] All the other are with embodiment 1.

[0063] The device has the following positive effects, which are embodied in:

[0064] 1. The hopper of this device is located in the first feeding pipe 13, the second feeding pipe 36, the first reducer 9, the second reducer 27, the first motor 11, the second mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com