Roller mill

A roller mill and grinding machine technology, applied in the field of roller mills, can solve the problems of expensive, unsuitable for complete, uniform and continuous material transportation, unable to guarantee the supply of raw materials, etc., and achieve the effect of energy saving and reliable continuous material transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

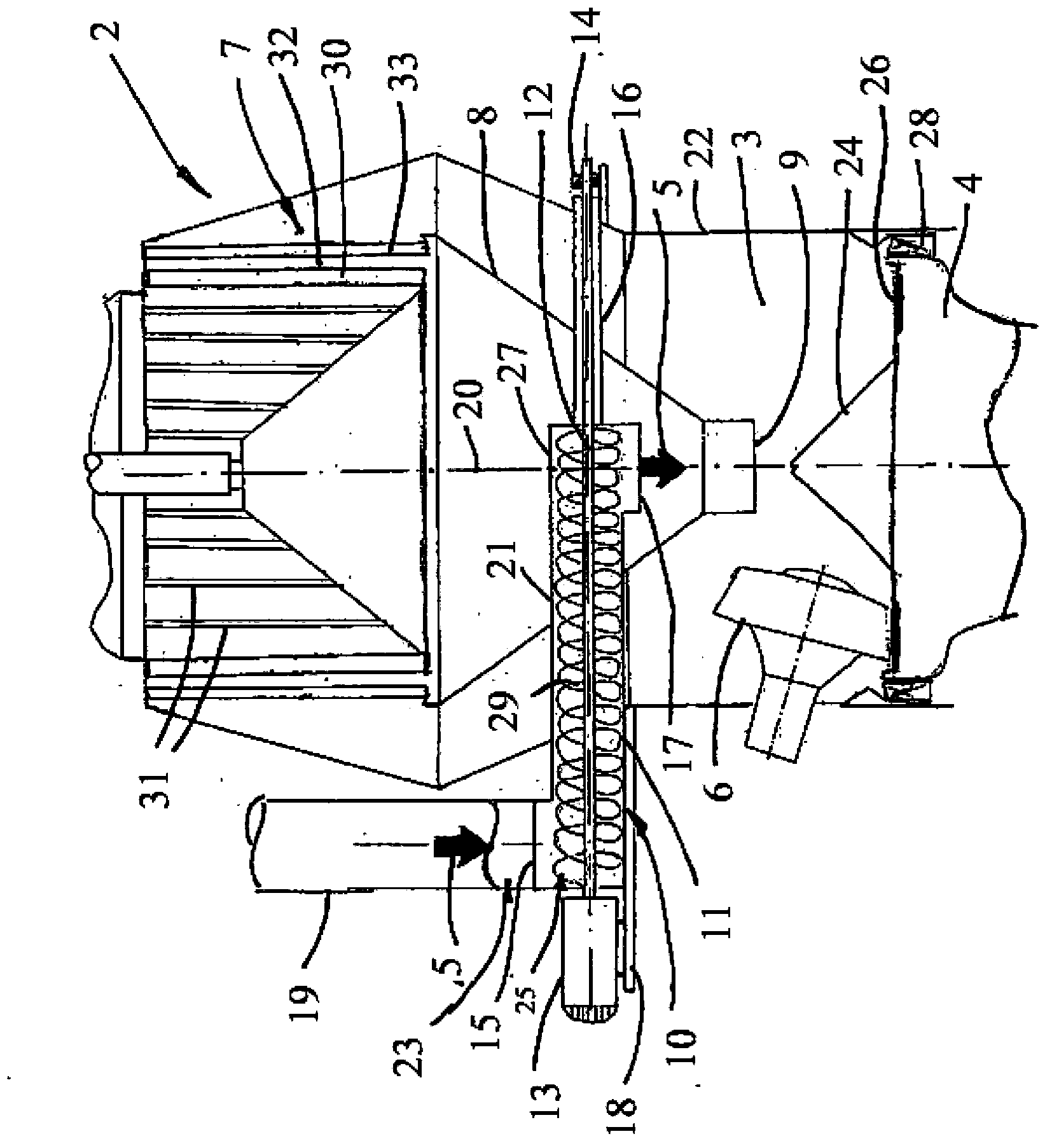

[0034] The roller mill 2 comprises a grinding disc 4 which rotates about a longitudinal axis 20 . The grinding disc 4 is provided with a grinding track 26 on which a grinding bed is formed from the raw material to be ground (not shown). Grinding rollers 6 arranged in fixed form and force-impacted form roll on this grinding bed with the assistance of a (not shown) suspension system and grind the raw material 5 conveyed with the assistance of a conveying system.

[0035] Only one grinding roller 6 is shown schematically in the figures. In principle, two, three, four or more grinding rollers can be arranged.

[0036] The ground abrasive material (not shown) is conveyed to the classifier 7 for classification in an updraft (not shown) which is conveyed to the Grinding chamber 3 , classifier 7 is arranged above grinding chamber 3 and is integrated into roller mill 2 in this exemplary embodiment.

[0037] The classifier 7 is provided with a rotor 30 which rotates about the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com