Preparation method of titanium-based titanium dioxide nanotube stannic oxide electrode

A technology of titanium dioxide and tin dioxide, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of easy cracks on the coating surface, low service life of electrodes, and poor stability etc. to achieve the effects of low cost, improved electrocatalytic performance, and increased catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the titanium-based titanium dioxide nanotube tin dioxide electrode of the present invention adopts anodic oxidation, electrodeposition and thermal oxidation to prepare the titanium-based titanium dioxide nanotube tin dioxide electrode, specifically comprising the following steps:

[0016] The first step: prepare titanium dioxide nanotubes on the titanium substrate by anodic oxidation method:

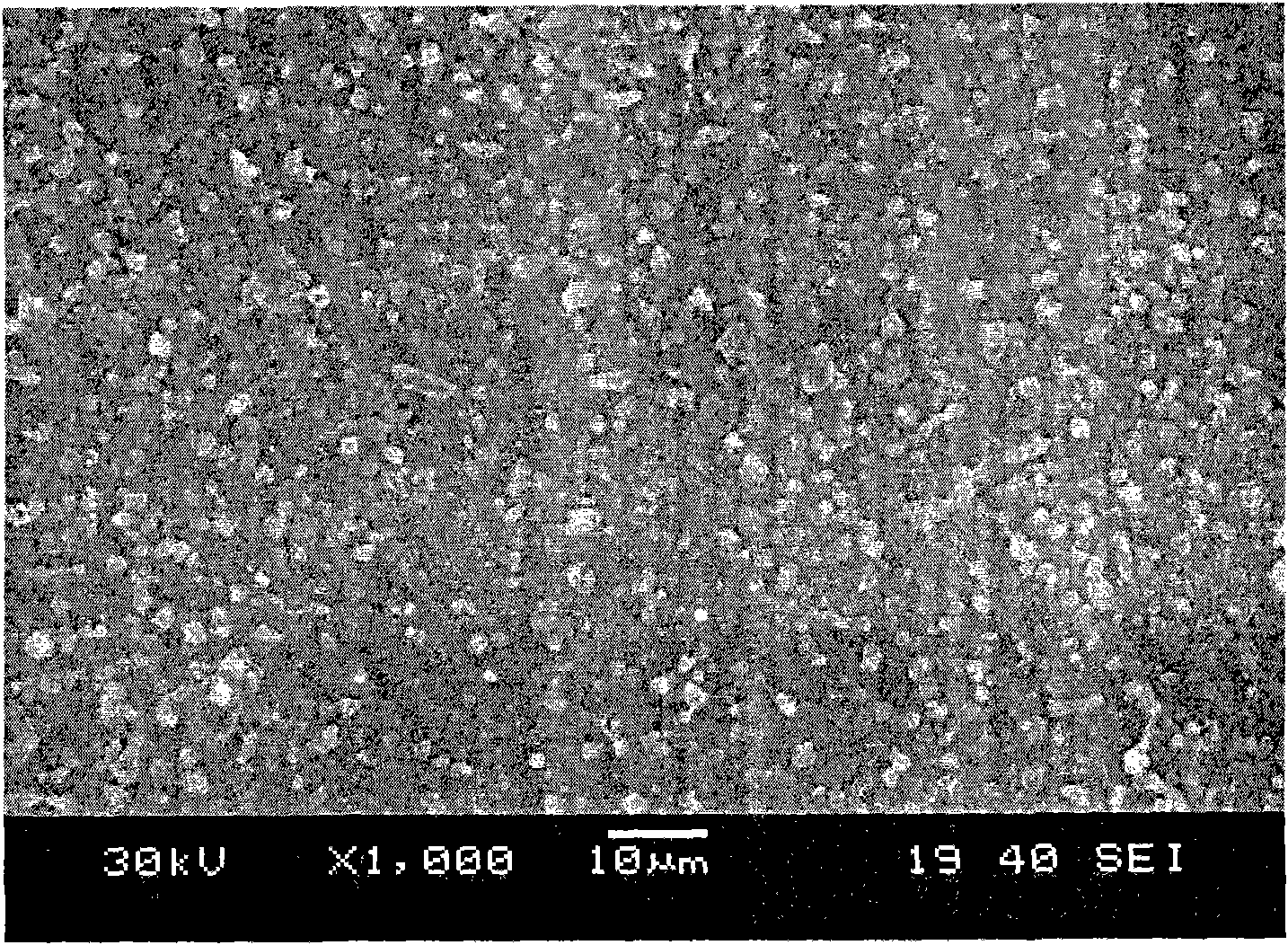

[0017] The surface of the titanium sheet is polished smooth, cleaned and used as the anode, with stainless steel as the cathode, the DC voltage is controlled at 20-25V, and anodic oxidation is performed in the electrolyte of potassium fluoride, hydrogen fluoride and sulfuric acid, and the electrolyte is 0.07-0.08mol / Mixed solution of L potassium fluoride, 0.07~0.08mol / L hydrogen fluoride and 0.95~1.05mol / L sulfuric acid, the anodizing time is 40~70min, take out the anodized titanium substrate, rinse it, heat and roast after air drying, The heating and ca...

Embodiment 1

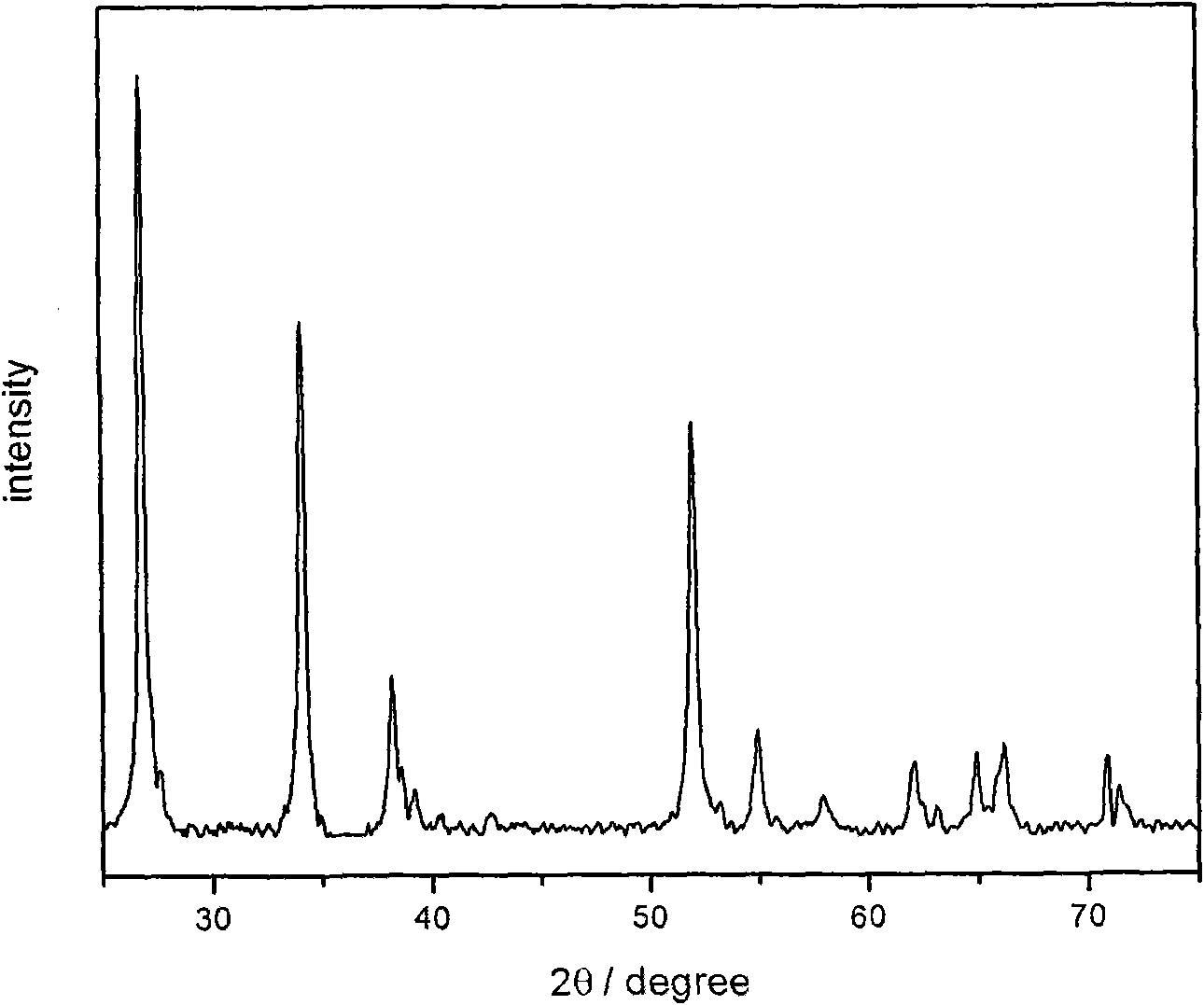

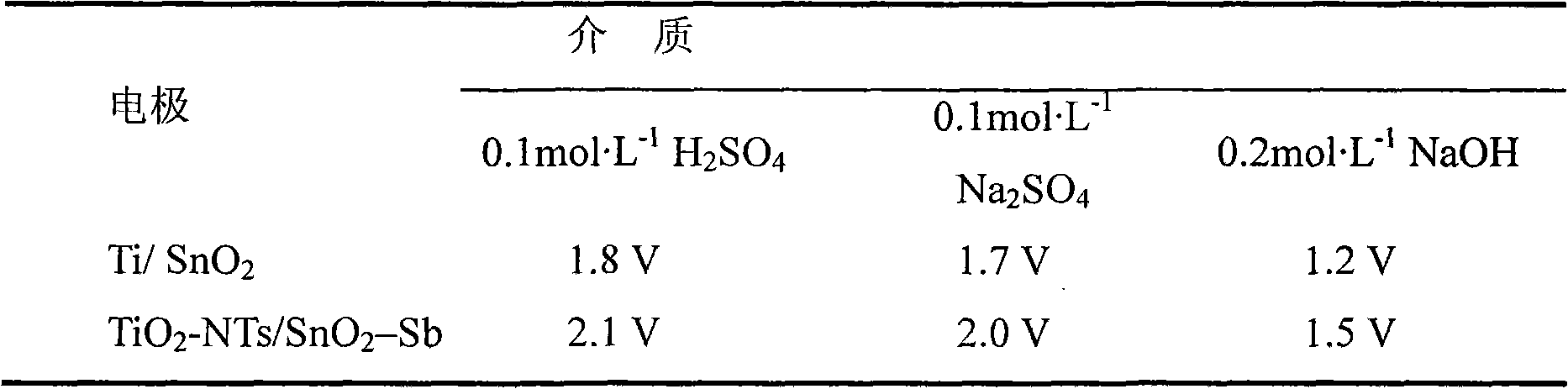

[0022] Cut the titanium plate into a size of 1.0cm×3.0cm, polish the titanium surface with sandpaper until the metal luster, remove the oil on the surface of the titanium substrate, and then heat it in 18wt% HCl solution for 15min to remove the oxide layer, rinse with distilled water and place Reserve in distilled water. The treated titanium plate is used as the anode, and the stainless steel plate of the same size is used as the cathode. The electrolyte is a mixed solution of 0.07mol / L potassium fluoride, 0.08mol / L hydrogen fluoride and 0.95mol / L sulfuric acid, and the distance between the electrodes is controlled to be 1cm. The voltage is 20V, after anodizing for 60min, the sample is taken out, rinsed with deionized water, air-dried naturally, placed in a muffle furnace, heated to 500°C with a temperature program of 1°C / min, and then roasted for 3 hours to obtain titanium-based titanium dioxide nanoparticles Tube. The titanium matrix prepared with titanium dioxide nanotubes...

Embodiment 2

[0030]The pretreatment steps of the titanium plate are the same as those in Example 1. The treated titanium plate is used as the anode, and the stainless steel plate of the same size is used as the cathode. The electrolyte is a mixed solution of 0.08mol / L potassium fluoride, 0.07mol / L hydrogen fluoride and 1.05mol / L sulfuric acid, and the distance between the electrodes is controlled to be 1cm. The voltage was 25V, anodized for 40min, rinsed with deionized water, air-dried naturally, placed in a muffle furnace, heated to 550°C with a temperature program of 2°C / min, and then calcined for 3 hours to prepare titanium-based titanium dioxide nanotubes. The titanium substrate prepared with titanium dioxide nanotubes was used as the cathode, and the stainless steel of the same size was used as the anode, and the current density was controlled at 4mA / cm 2 , first electrodeposit antimony in a mixed solution of 0.015mol / L antimony trichloride and 0.1mol / L citric acid for 0.5min, then el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com