Preparation method of efficient organic silicon emulsion water-proofing agent for reinforcing cement mortar concrete

A technology of silicone emulsion and cement mortar, which is applied in the field of cement mortar overall reinforcement waterproofing agent, can solve the problems of concrete compressive strength change, waterproof layer wear, poor water repellency of concrete, etc., and achieve increased fluidity, reduced capillary pores, and strong strength Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

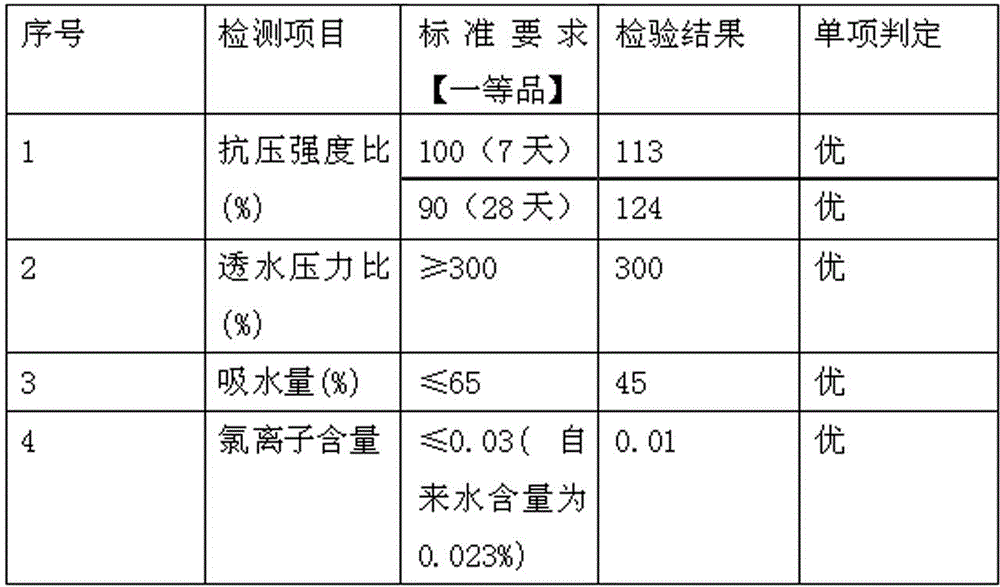

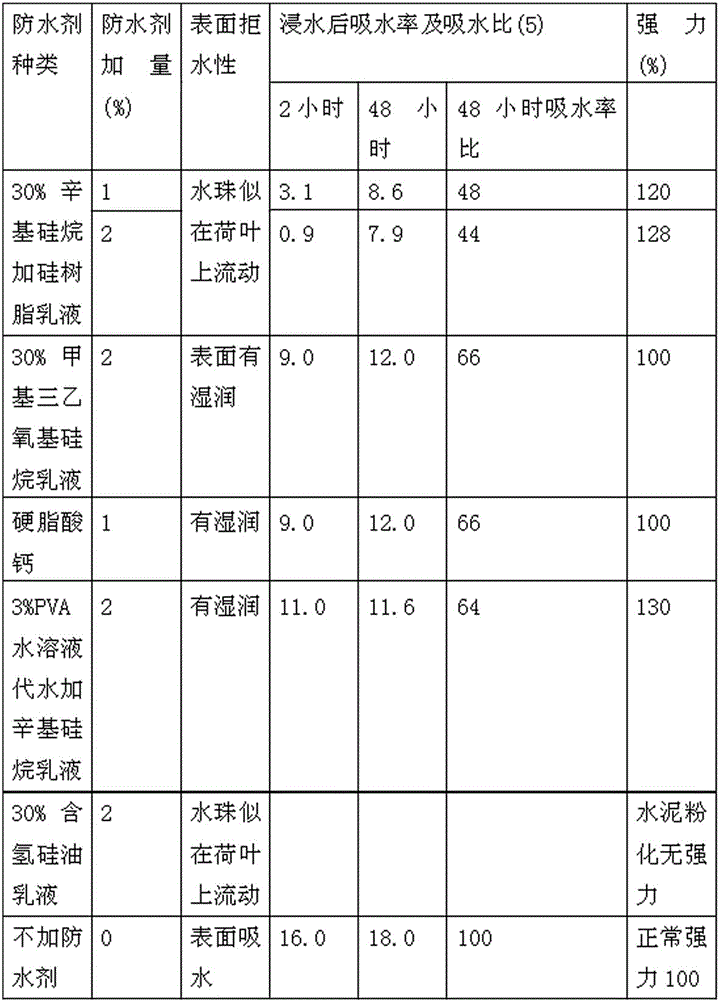

[0015] Below in conjunction with accompanying table and embodiment the present invention is further described.

[0016] A kind of preparation method of cement mortar concrete reinforced high-efficiency silicone emulsion waterproofing agent, its steps are as follows:

[0017] The first step: the synthesis of octyltriethoxysilane, add 200g of octene and 50g of isopropanol into a 500ml three-necked flask, fill it with nitrogen, heat it in a water bath to 80°C, and use the isopropanol solution of chloroplatinic acid as a catalyst 150g of triethoxysilane was added dropwise, reacted under reflux for several hours, isopropanol was evaporated under normal pressure, and octyltriethoxysilane was evaporated under reduced pressure, with a yield of more than 90%;

[0018] The second step: the synthesis of methyl silicone resin prepolymer, in a 500ml three-necked flask, add 200g of methyltriethoxysilane, 100g of dimethylsiloxane ring body, and 10g of trifluoromethanesulfonic acid as a catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com