Automatic straightening method and system for hydraulic supports and scraper conveyors of fully-mechanized coal mining working faces

A technology of scraper conveyor and fully mechanized mining face, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve the problems of unable to indicate the straightened state and no reference point, etc., so as to achieve neat arrangement and avoid The bending is too large to ensure the effect of three straight and one flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

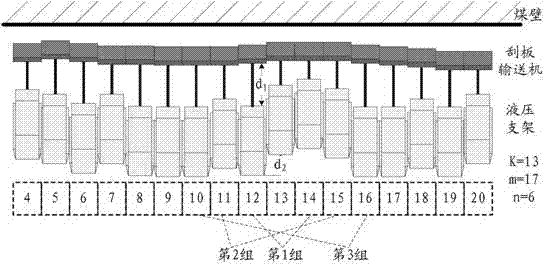

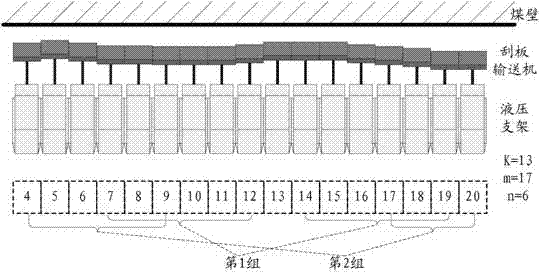

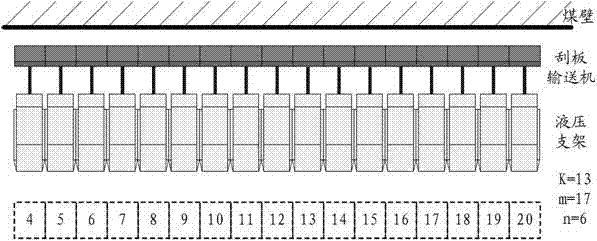

[0023] see figure 1 As shown, a fully mechanized mining face hydraulic support and scraper conveyor automatic straightening method, including the following steps:

[0024] Step S101 , during the continuous advancing process of the fully mechanized mining face, the relative position between every two hydraulic supports is obtained through the first travel sensor installed on each hydraulic support.

[0025] In the present invention, a travel sensor for reflecting the relative position between the hydraulic supports is installed on each hydraulic support, and the relative position between every two hydraulic supports can be obtained by detecting the signal of the above travel sensor by the electro-hydraulic control system. As a better embodiment, the process of acquiring the relative position between every two hydraulic supports through the first stroke sensors installed on each hydraulic support may specifically include the following: through the sensor of the first stroke sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com