On-line recovery production line for cut tobacco of defective cigarettes

A technology for waste cigarettes and production lines, which is applied to tobacco, cigarette manufacturing, conveyor objects, etc., can solve the problems of high content of shredded paper, direct use of unqualified shredded tobacco, incomplete separation of shredded tobacco and rolled paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the implementation given in the accompanying drawings, but the content of the present invention is not limited thereto.

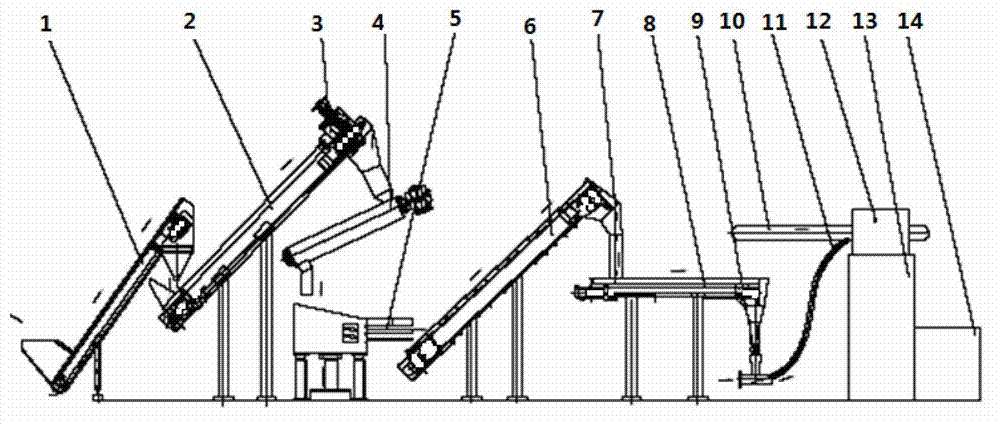

[0033] Such as figure 1 , the invention provides an online waste cigarette shredded tobacco recycling production line, which includes a waste cigarette adding device (1), a waste cigarette straightening mechanism (2), a waste cigarette breaking mechanism (3), and a waste cigarette loosening mechanism (4), waste cigarette vibrating screening mechanism (5), waste shredded tobacco separator conveying mechanism (6), metering device (7), frequency conversion speed regulating conveying belt (8), air lock (9), electric control butterfly valve ( 10), wind-driven wire-feeding aluminum tube (11), cigarette makers silk hopper (12), cigarette makers (13), waste cigarette collection box (14);

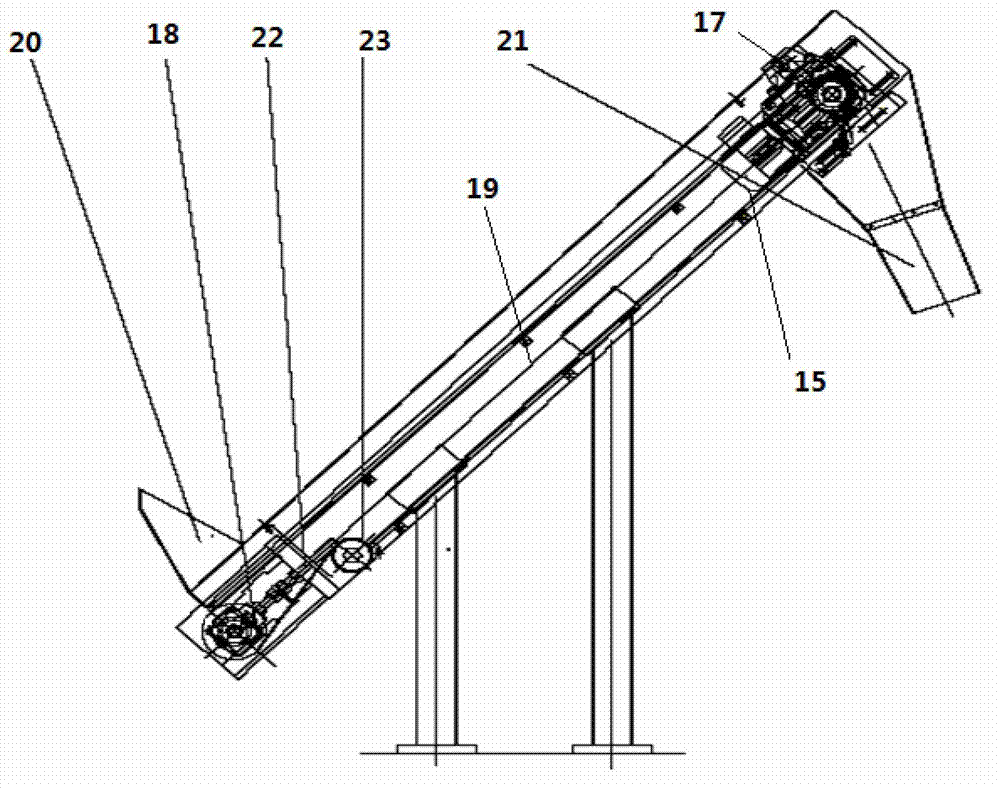

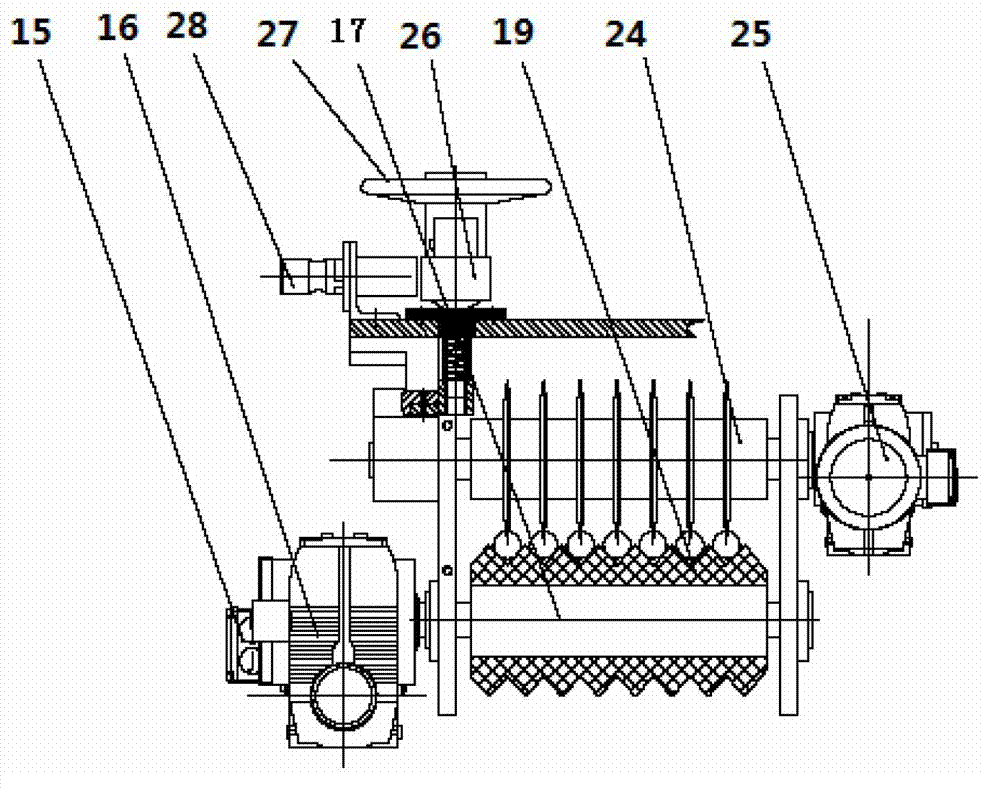

[0034] The waste cigarette straightening belt mechanism 2 is arranged below the waste c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com