Field assembling optical connector

An optical connector, on-site assembly technology, applied in the direction of light guide, optics, instruments, etc., can solve the problem that the optical connector is not suitable for on-site setting, etc., to achieve the effect of simple assembly, improved assembly efficiency, and improved alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only for explaining the present invention, and are not intended to limit the scope of the present invention. In addition, the present invention can be implemented in a variety of ways other than the following examples, and within the spirit and principles of the present invention, any modifications, equivalent replacements, improvements, etc., should be included in the protection of the present invention. within range.

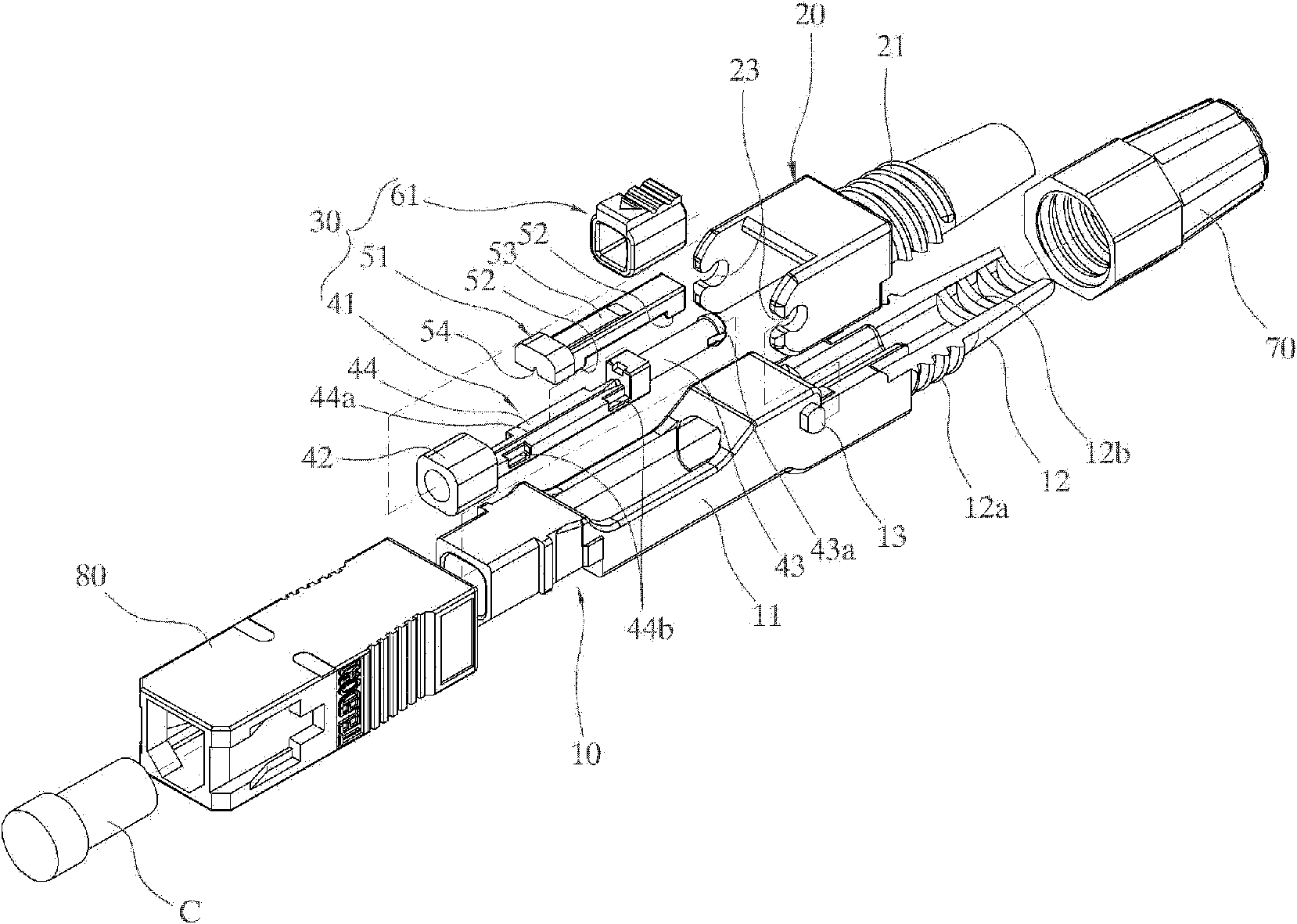

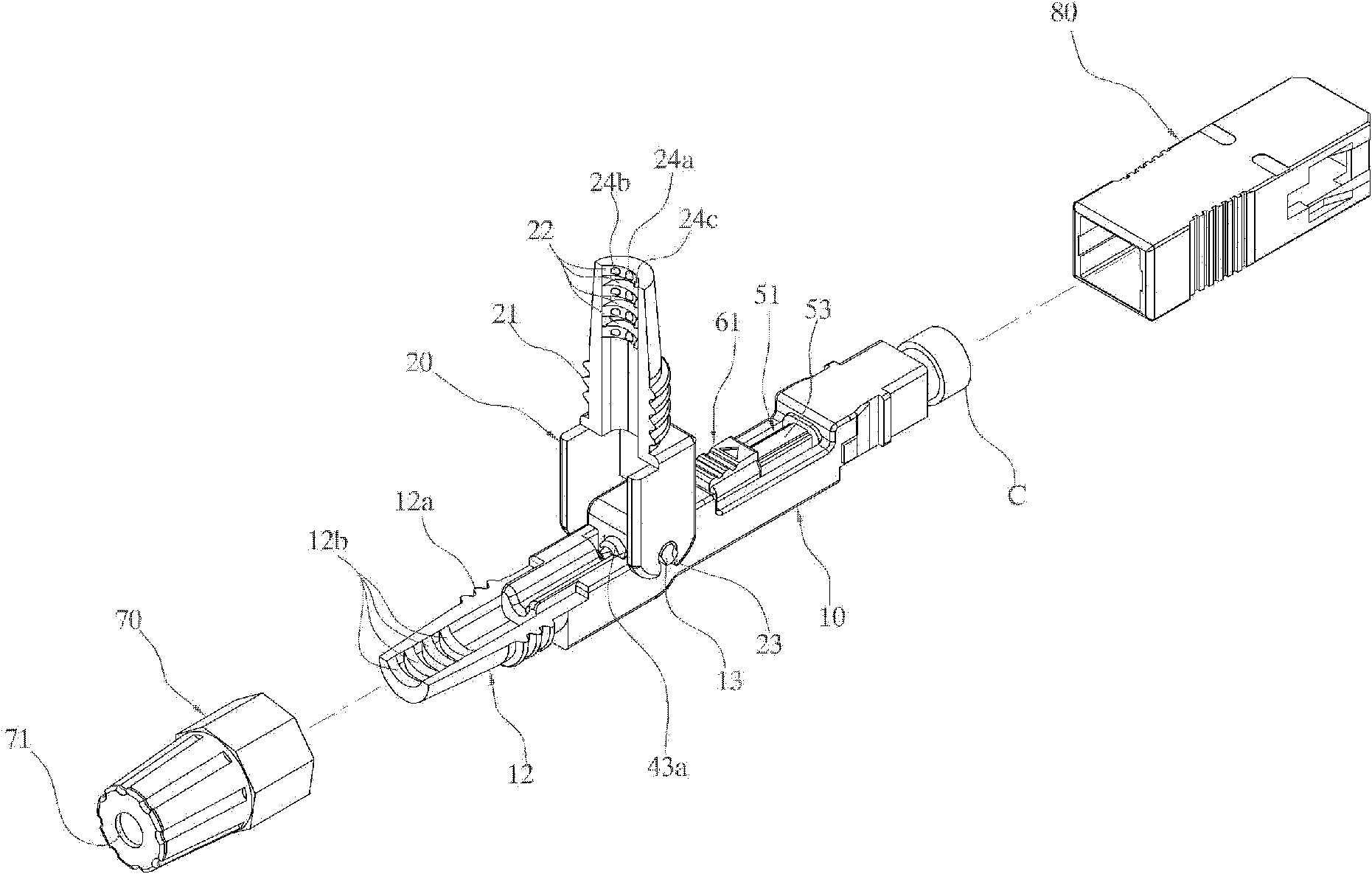

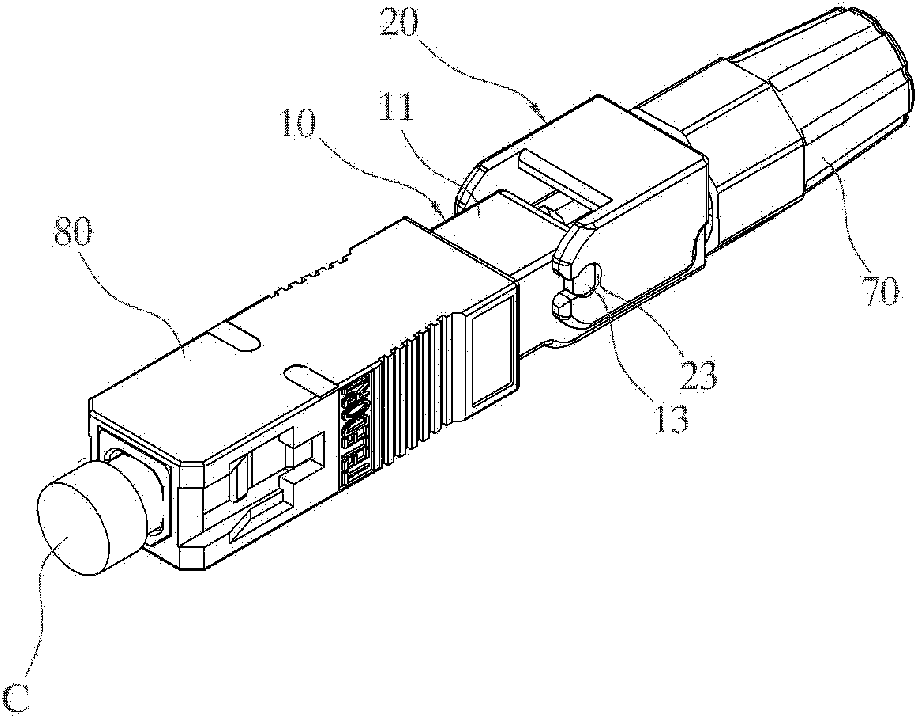

[0023] figure 1 and figure 2 It is an exploded perspective view of the field assembly type optical connector according to the embodiment of the present invention; image 3 yes figure 1 combined stereogram; Figure 4 It is a front cross-sectional view of a state where a circular optical cable is fixed by a field-assembled optical connector according to an embodiment of the present invention; Figure 5 It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com