Laser marking device capable of feeding and discharging materials automatically

A laser marking equipment and automatic loading and unloading technology, applied in printing and other directions, can solve the problems of sorting and placement of marking products, marking position deviation, time-consuming and labor-intensive, etc., to reduce investment, improve marking efficiency, and improve marking efficiency. The effect of standard efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

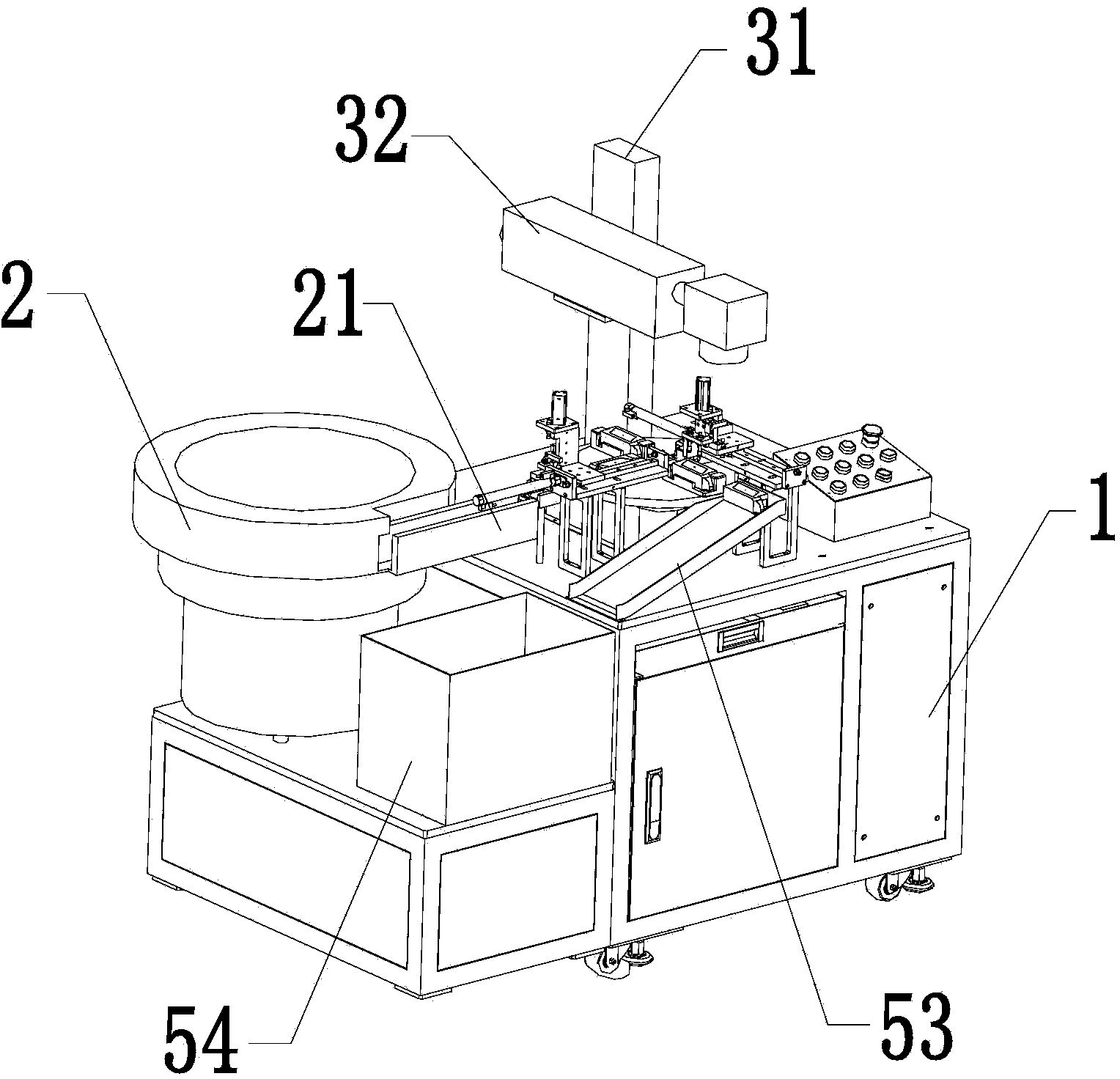

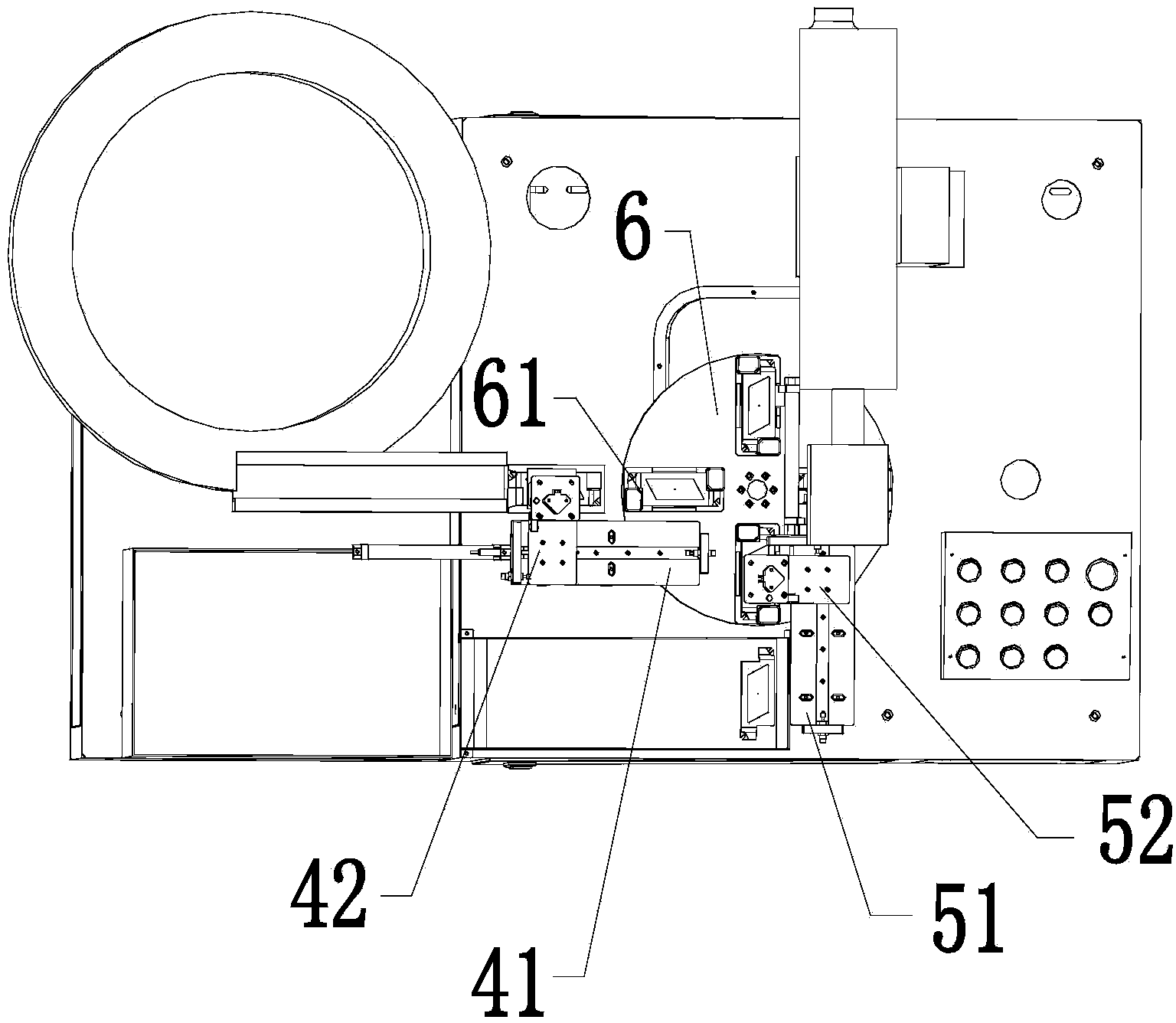

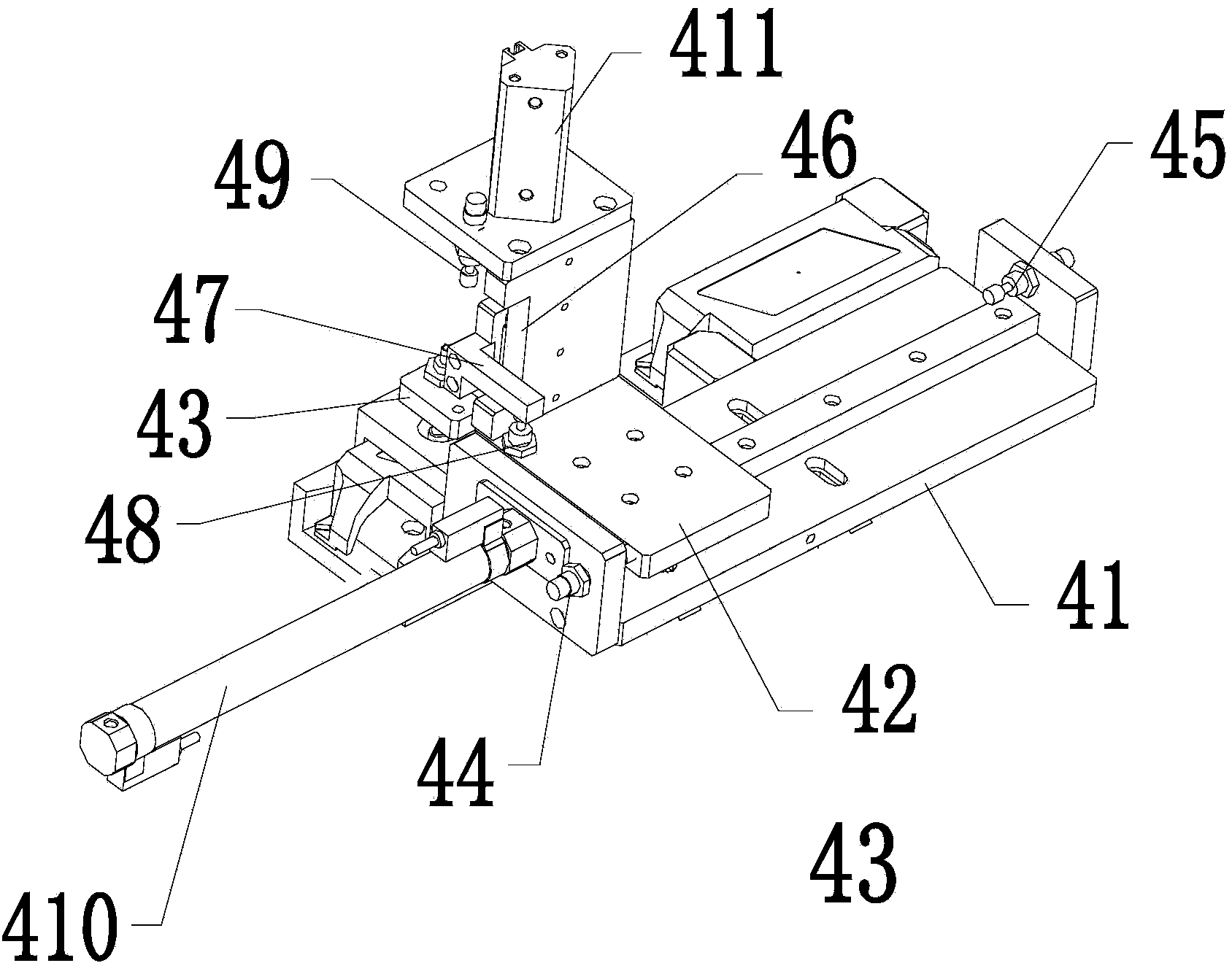

[0037] As shown in Figures 1 to 4, the automatic loading and unloading laser marking equipment of the present invention includes a machine base 1, a vibrating plate 2, a laser engraving mechanism and a central processing unit for controlling the work of the automatic loading and unloading laser marking equipment; The disc 2 is arranged on the machine base 1, and the vibrating disc 2 is provided with a conveying track 21; the said machine base 1 is provided with a feeding mechanism, a feeding mechanism and a rotary disk 6 that can rotate around the center; At the blanking place of the conveying track 21; the rotary disk 6 is located at the blanking place of the reclaiming mechanism, and the rotary disk 6 is provided with four discharging racks 61, and the laser engraving mechanism is placed at the punching place of the rotary disk 6. a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com