Full-automatic laser marking machine for double-station substrate

A laser marking machine, fully automatic technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of wasting time and low efficiency, and achieve the effects of high efficiency, improved efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

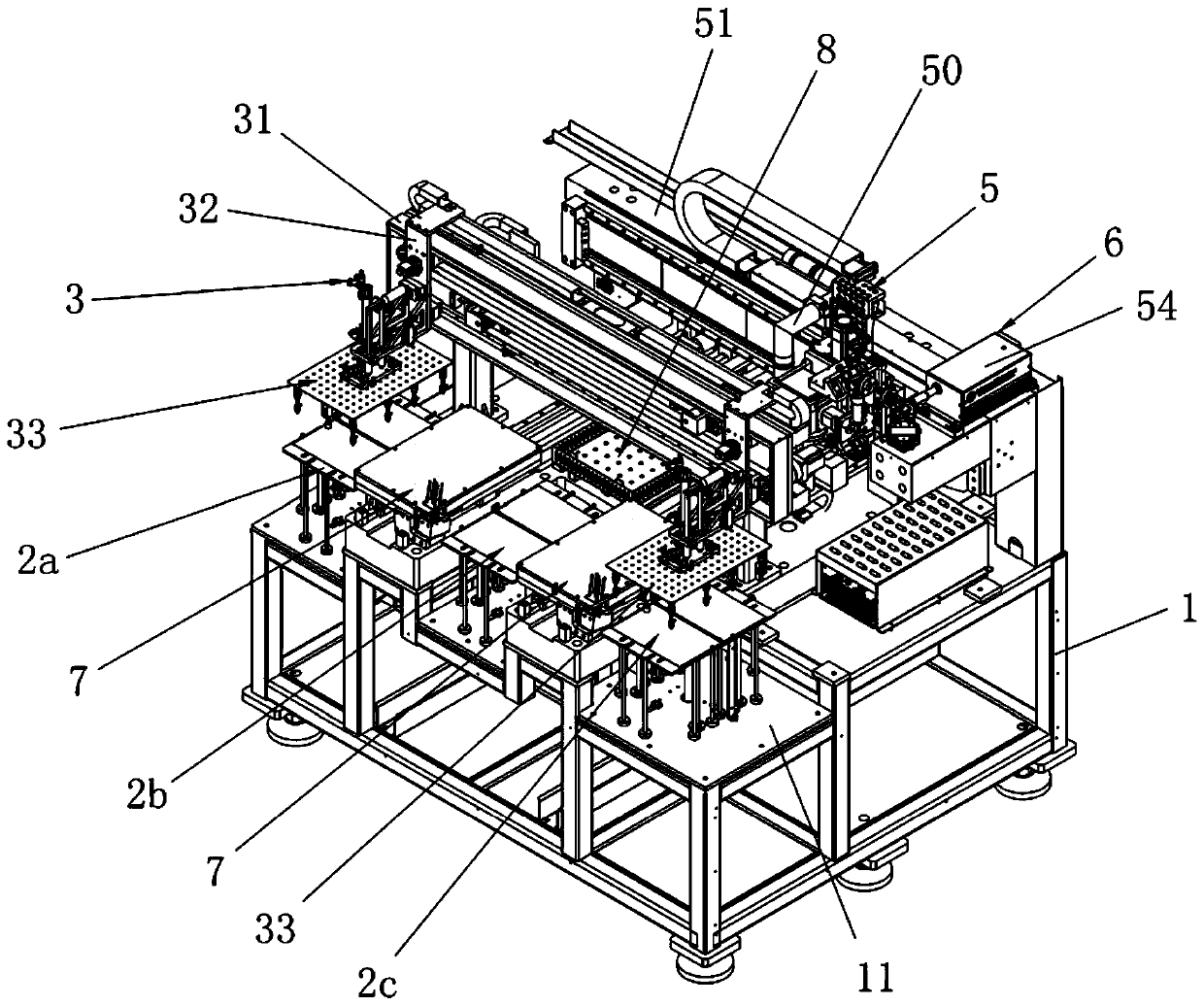

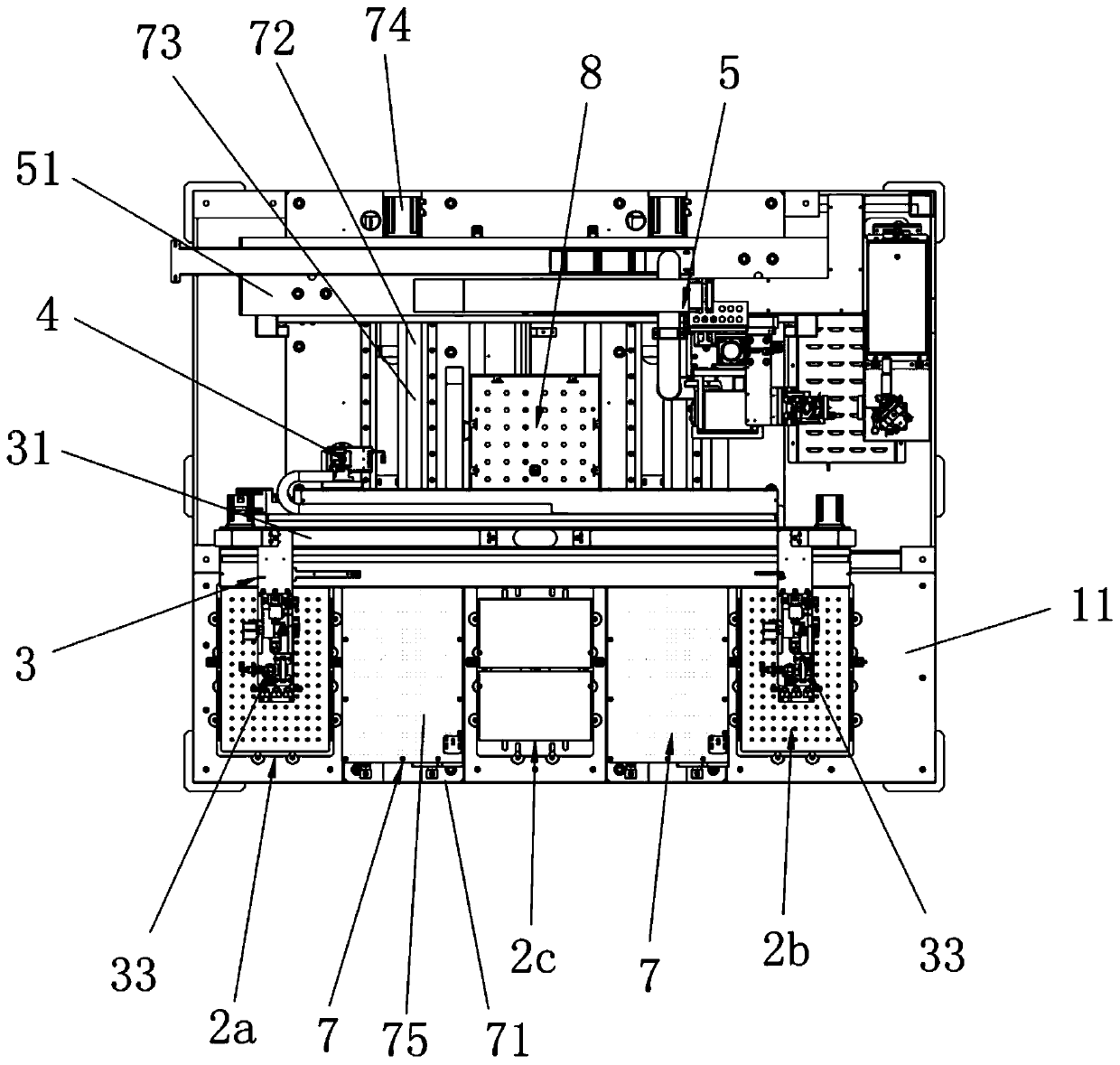

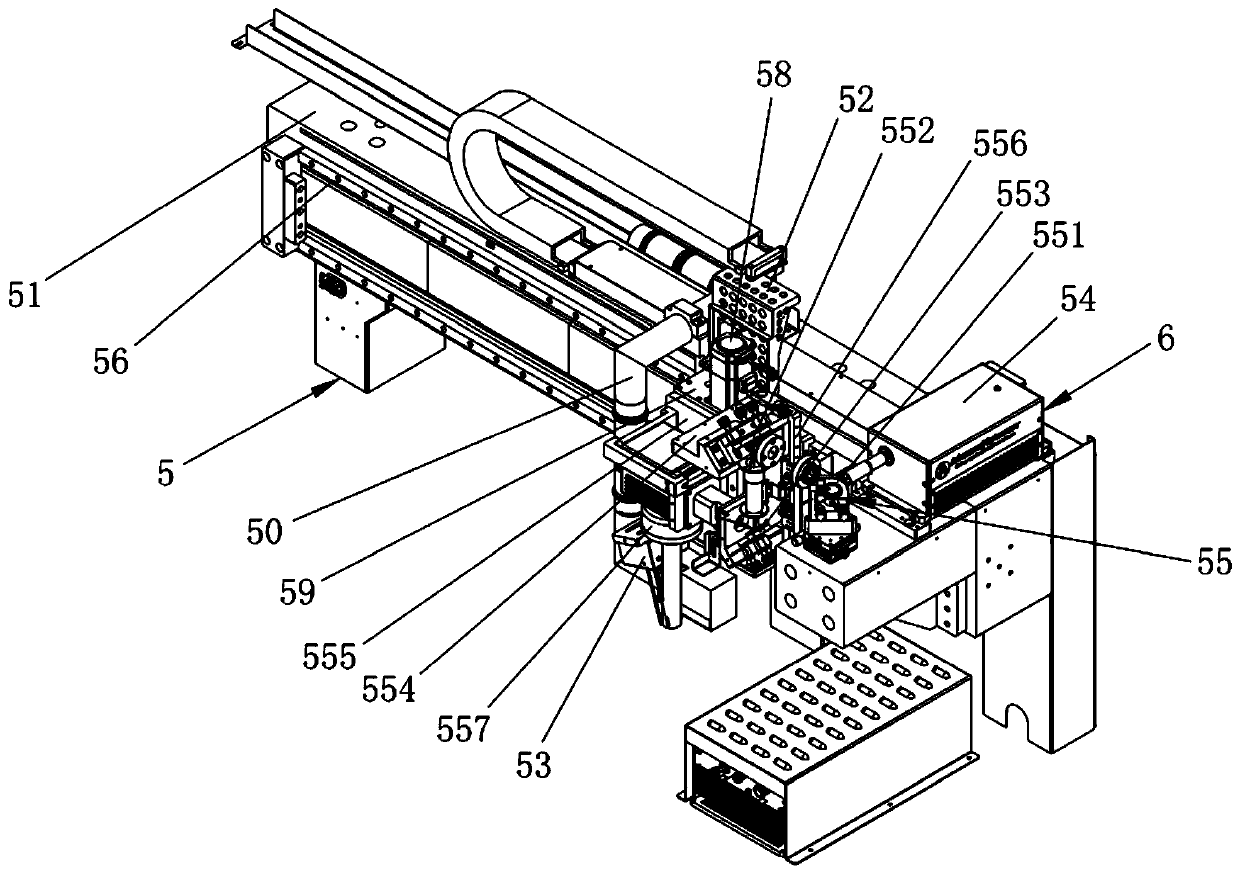

[0029] Such as Figure 1 to Figure 10 As shown, a double-station substrate automatic laser marking machine provided by the present invention includes a frame 1, a machine platform 11 arranged on the frame 1, a substrate feeding mechanism 2a arranged on the frame 1, a partition Plate feeding mechanism 2b, finished product collection mechanism 2c, NG product collection mechanism 8, manipulator transfer mechanism 3, camera scanning transfer mechanism 4, code scanning mechanism 5, laser component 6 and two loading workbench mechanisms 7, The loading table mechanism 7 is provided with an upper and lower material level 71. The manipulator transfer mechanism 3 is used to alternately transfer the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com