Comprehensive tanning agent for furs and no-dry-washing and no-chromium tanning process thereof

A tanning agent and chrome-free tanning technology, applied in the treatment of small raw hide/big raw hide/leather/fur, chemical treatment and application of small raw hide/big raw hide/leather skin/fur, and can solve hair damage and heavy metal pollution in water , high cost issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

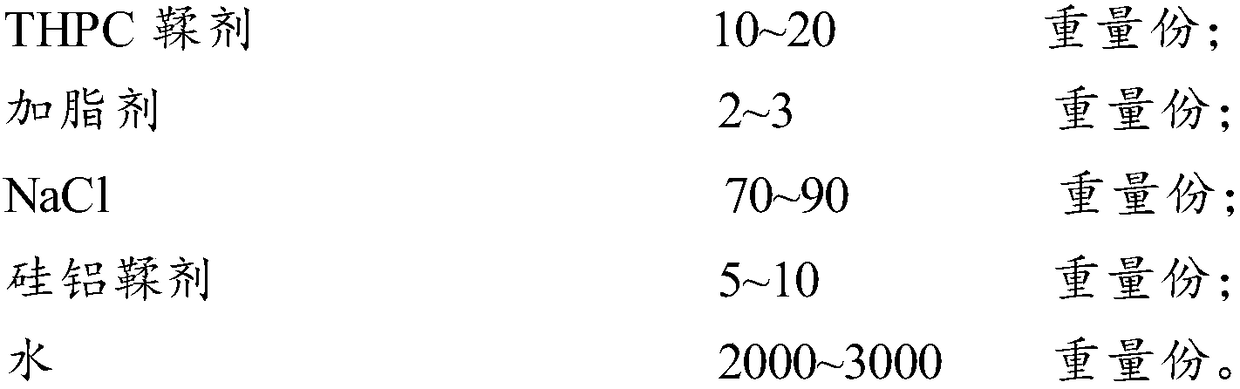

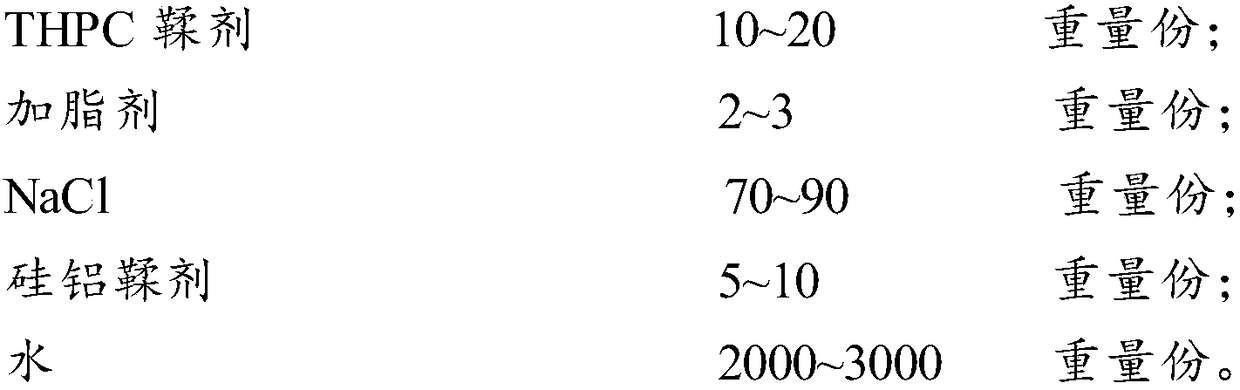

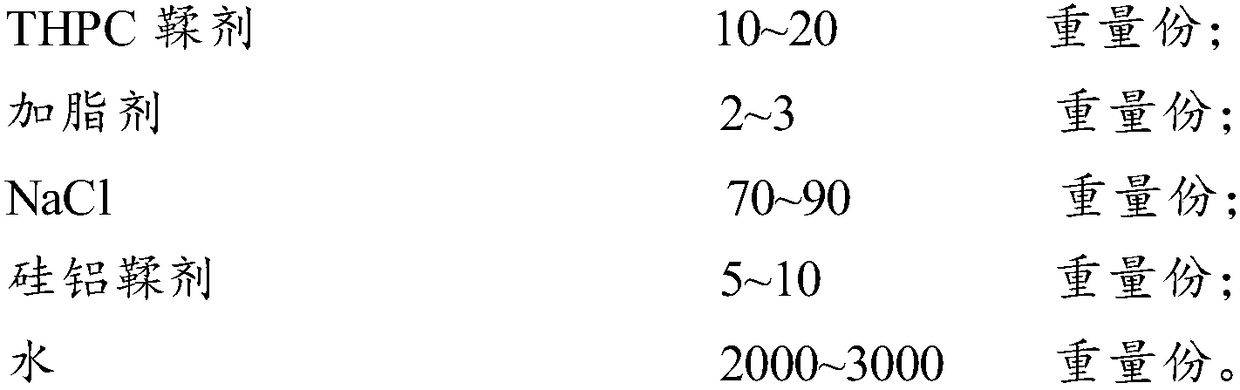

Method used

Image

Examples

Embodiment 1

[0111] Washing - fleshing - degreasing - pickling - softening process is the same as the traditional process.

[0112] THPC pre-tanning: add 35°C brine at 6 Baume degrees to the drum, adjust the pH value to 3.2 with sulfuric acid 0.3-0.5g / l, add the softened hides according to the ratio of water to skin at 12:1, and turn for 5 Minutes later, add 15g / L THPC tanning agent, continue to rotate for 180 minutes, then use 2-3g / l of soda ash to increase the pH to 5.0-6.0, and rotate for 60 minutes again.

[0113] Secondary degreasing: According to the mass ratio of water and leather is 10:1, add water at 45-50°C to the drum, use (TFL company) degreasing agent BORRON SE 2g / L as the main degreasing agent, and rotate for 120 minutes for degreasing .

[0114] Retanning with silicon aluminum tanning agent: according to the mass ratio of water and hide is 12:1, add water at 35°C and degreased hide into the drum, and after rotating for 5 minutes, add 3g / L (Trumpler company) fatliquoring age...

Embodiment 2

[0123] Washing - fleshing - degreasing - pickling - softening process is the same as the traditional process.

[0124] THPC pre-tanning: Add 6 Baume degrees of 35°C salt water to the drum, adjust the pH value to 3.3 with sulfuric acid 0.3-0.5g / l, add the softened hides according to the ratio of water to skin at 13:1, and turn for 5 Minutes later, add 13g / L THPC tanning agent, continue to rotate for 180 minutes, then use 2-3g / l of soda ash to raise the pH to 5.0-6.0, and rotate for 60 minutes again.

[0125] Secondary degreasing: According to the mass ratio of water and leather is 10:1, add water at 45-50°C to the drum, use (TFL company) degreasing agent BORRON SE 3g / L as the main degreasing agent, and rotate for 150 minutes for degreasing .

[0126] Retanning with silicon-aluminum tanning agent: add 35°C water and degreased hide into the drum according to the mass ratio of water and hide at 14:1, and add 2g / L (Trumpler company) fatliquoring agent after rotating for 5 minutes ...

Embodiment 3

[0135] Washing - fleshing - degreasing - pickling - softening process is the same as the traditional process.

[0136] THPC pre-tanning: Add 7 Baume degrees of 35°C salt water to the drum, adjust the pH value to 3.4 with 0.3-0.5 g / l sulfuric acid, add the softened hides according to the water-to-hide mass ratio of 13:1, and rotate for 5 Minutes later, add 12g / L THPC tanning agent, continue to rotate for 150 minutes, then use 2-3g / l of soda ash to increase the pH to 5.0-6.0, and rotate for 90 minutes again.

[0137] Secondary degreasing: According to the mass ratio of water and leather is 10:1, add water at 45-50°C to the drum, use (BASF company) degreasing agent EUSAPON OE 2.5g / L as the main degreasing agent, and rotate for 120 minutes skim.

[0138] Silicon-aluminum tanning agent retanning: according to the mass ratio of water and hide is 11:1, add water at 35°C and degreased hide into the drum, rotate for 5 minutes, add 2.5g / L (Pulcar Chemicals company) Grease agent PELLAN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com