Leather-protective fat liquoring agent and preparation method thereof

A fatliquoring agent, leather technology, applied in leather impregnation, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc., can solve the problem of poor protection performance and fatliquoring efficiency Low surface energy, improve fatliquoring efficiency, and improve the effect of plumpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

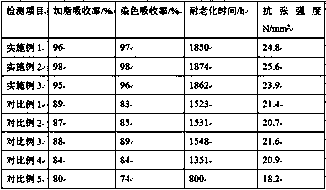

Examples

preparation example Construction

[0025] The preparation method of fatliquoring active agent is:

[0026] (1) Take the active monomer and add the acid active agent according to the mass ratio of 2~5:5~9, raise the temperature to 80~90°C and stir and mix for 60~90min, cool to 60~70°C to obtain the cooled product, take the cooled product according to the mass Ratio 10~15: 2~5 Add sodium sulfite, then add 1~3% sodium nitrate of cooling material, stir and mix at 60~70°C for 10~20min to get the mixture;

[0027] (2) Take sodium bisulfite and add deionized water at a mass ratio of 1~3:10~20, stir and mix for 20~30min to obtain a mixed solution, take the mixed solution and add it dropwise to the mixture at a mass ratio of 2~5:30~40 , stir and mix at 60~70°C for 60~90min to obtain a stirred mixture, take the stirred mixture and add distilled water at a mass ratio of 5~10:2~5, stir and mix at 70~80°C for 2~4h, and cool to room temperature to obtain Fatliquoring active agent.

[0028]The preparation method of the load...

Embodiment 1

[0036] Polypropylene carbonate: molecular weight is 3000.

[0037] The active monomer is: take 12-hydroxystearic acid and add diethanolamine at a mass ratio of 2:1, heat up to 120°C, add p-toluenesulfonic acid with 1% weight of diethanolamine, keep warm at 125°C for 3 hours, cool to room temperature, Pressure distillation, that is, the active monomer.

[0038] The acid active agent is: 3,3',4,4'-biphenyltetracarboxylic dianhydride.

[0039] The preparation method of fatliquoring active agent is:

[0040] (1) Take the active monomer and add the acid active agent according to the mass ratio of 2:5, heat up to 80°C and stir and mix for 60 minutes, cool to 60°C to obtain a cooling product, take the cooling product and add sodium sulfite at a mass ratio of 10:2, and then add cooling Sodium nitrate with 1% substance mass was stirred and mixed at 60°C for 10 minutes to obtain a mixture;

[0041] (2) Take sodium bisulfite and add deionized water at a mass ratio of 1:10, stir and mi...

Embodiment 2

[0050] Polypropylene carbonate: molecular weight is 3000.

[0051] The active monomer is: take 12-hydroxystearic acid and add diethanolamine at a mass ratio of 7:3, heat up to 130°C, add p-toluenesulfonic acid with 3% weight of diethanolamine, keep warm at 135°C for 5h, cool to room temperature, reduce Pressure distillation, that is, the active monomer.

[0052] The acid active agent is: take maleic anhydride.

[0053] The preparation method of fatliquoring active agent is:

[0054] (1) Take the active monomer and add the acid active agent according to the mass ratio of 5:9, raise the temperature to 90°C and stir and mix for 90 minutes, cool to 70°C to obtain a cooling product, take the cooling product and add sodium sulfite at a mass ratio of 15:5, and then add cooling Sodium nitrate with 3% substance mass was stirred and mixed at 70°C for 20 minutes to obtain a mixture;

[0055] (2) Take sodium bisulfite and add deionized water at a mass ratio of 3:20, stir and mix for 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com