Fatting agent for normal-temperature fatting

A fatliquoring agent and fatliquoring technology, which can be used in the treatment of small raw hides/large raw hides/leather/furs, leather impregnation, chemical treatment of small raw hides/large raw hides/leather hides/furs, etc. , The company increases the cost burden, a large amount of energy consumption and other problems, and achieves the effect of good softness, excellent softness and excellent oiliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

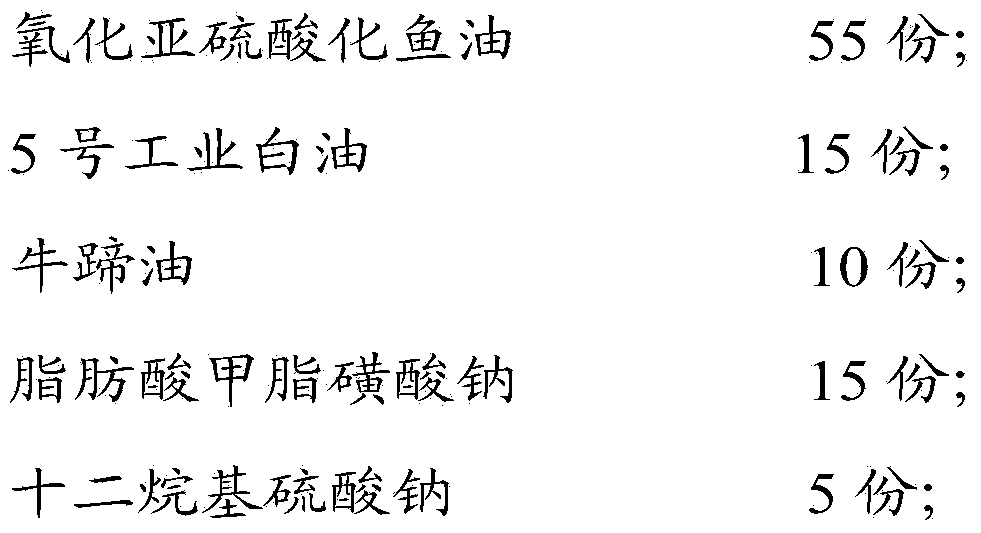

[0064] The leather fatliquor of the present embodiment consists of:

[0065]

[0066] The above-mentioned raw materials are prepared according to the stated parts, and all of them are added into the reactor, mixed and stirred evenly.

Embodiment 2

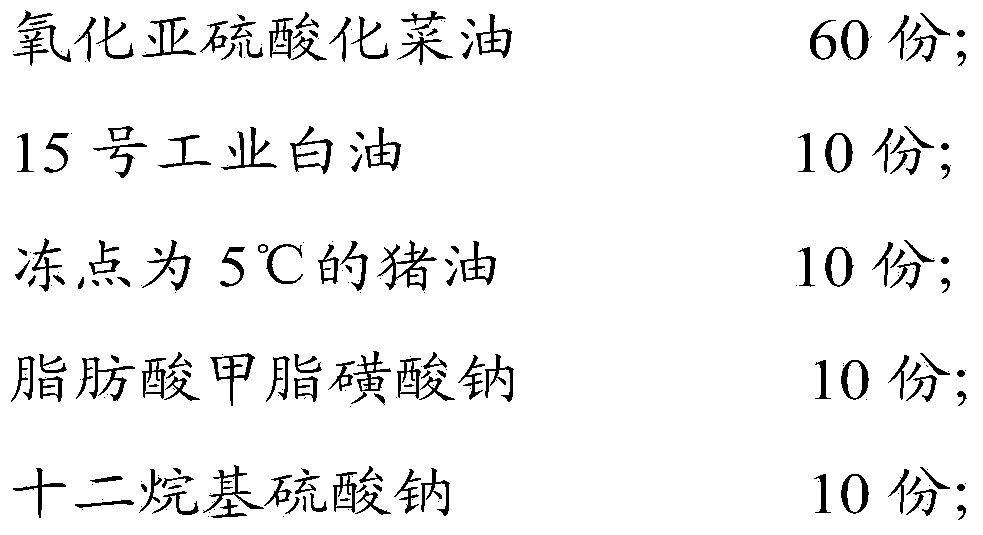

[0068] The leather fatliquor of the present embodiment consists of:

[0069]

[0070] The above-mentioned raw materials are prepared according to the stated parts, and all of them are added into the reactor, mixed and stirred evenly.

Embodiment 3

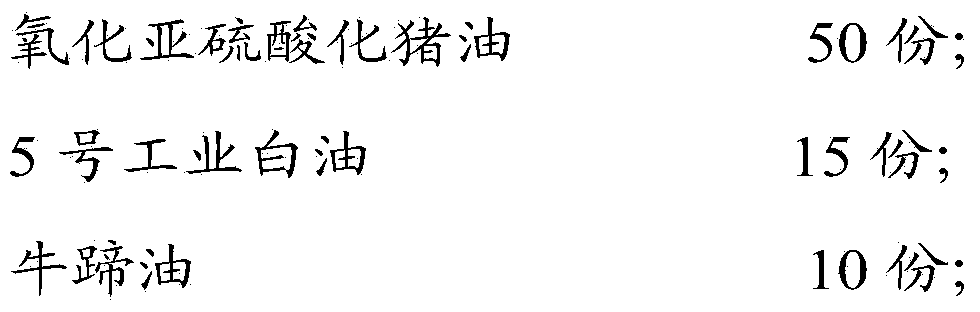

[0072] The leather fatliquor of the present embodiment consists of:

[0073]

[0074]

[0075] The above-mentioned raw materials are prepared according to the stated parts, and all of them are added into the reactor, mixed and stirred evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com