Preparing method of tearing electret film method antibacterial flame-retardant antistatic radiation-prevention fancy composite yarn

A flame-retardant, anti-static and anti-radiation technology, applied in yarn, textiles, papermaking, weft knitting, etc., can solve problems such as difficult to master process conditions, not soft hand feeling, high mass specific resistance, etc., and achieve unique appearance effect, rich Effect of color change, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

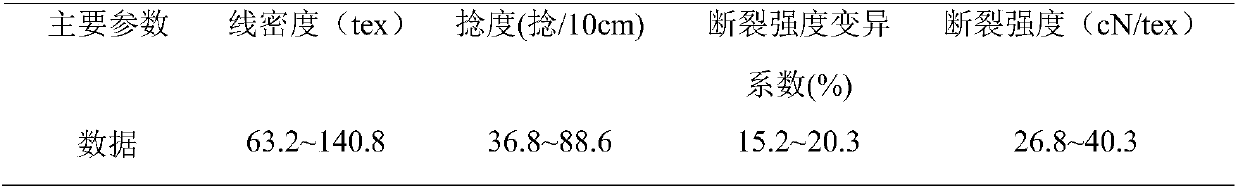

Embodiment 1

[0066] A kind of antibacterial, flame retardant, antistatic, anti-radiation anti-radiation flower made of aramid 1414, polytetrafluoroethylene (raw tape), flame-retardant viscose fiber, stainless steel staple fiber, silver fiber, Amicor fiber, and colored polyester fiber blended Take the composite yarn as an example, in which aramid fiber and polytetrafluoroethylene are selected as the core yarn, and the ply roving after twisting on the roving frame is used as the core yarn. The fixed yarn is colored polyester knot yarn, and the weight content of yellow colored polyester fiber in the blended yarn accounts for 50%, and the weight content of red colored polyester fiber accounts for 50%. The decorative yarns are two decorative yarns. The first decorative yarn is a flame-retardant yarn blended with flame-retardant viscose fiber and Amicor fiber. The weight content of the flame-retardant viscose fiber in the blended yarn accounts for 55%. Amicor The weight content of the fiber acco...

Embodiment 2

[0068] A kind of antibacterial, flame retardant, antistatic, anti-radiation anti-radiation flower made of aramid 1414, polytetrafluoroethylene (raw tape), flame-retardant viscose fiber, stainless steel staple fiber, silver fiber, Amicor fiber, and colored polyester fiber blended Take the composite yarn as an example, in which aramid fiber and polytetrafluoroethylene are selected as the core yarn, and the ply roving after twisting on the roving frame is used as the core yarn. The fixed yarn is colored polyester knot yarn, and the weight content of the blue colored polyester fiber in the blended yarn accounts for 60%, and the weight content of the red colored polyester fiber accounts for 40%. The decorative yarns are two decorative yarns. The first decorative yarn is a flame-retardant yarn blended with flame-retardant viscose fiber and Amicor fiber. The weight content of the flame-retardant viscose fiber in the blended yarn accounts for 40%. Amicor The weight content of the fibe...

Embodiment 3

[0070]A kind of antibacterial, flame retardant, antistatic, anti-radiation anti-radiation flower made of aramid 1414, polytetrafluoroethylene (raw tape), flame-retardant viscose fiber, stainless steel staple fiber, silver fiber, Amicor fiber, and colored polyester fiber blended Take the composite yarn as an example, in which aramid fiber and polytetrafluoroethylene are selected as the core yarn, and the ply roving after twisting on the roving frame is used as the core yarn. The fixed yarn is colored polyester knot yarn, and the weight content of yellow colored polyester fiber in the blended yarn accounts for 70%, and the weight content of red colored polyester fiber accounts for 30%. The decorative yarns are two decorative yarns. The first decorative yarn is a flame-retardant yarn blended with flame-retardant viscose fiber and Amicor fiber. The weight content of the flame-retardant viscose fiber in the blended yarn accounts for 70%. Amicor The weight content of the fiber accou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com