Leather material based on artificial grain surface layer, artificial grain surface layer and processing method

A processing method and technology of grain layer, applied in textiles and papermaking, etc., can solve the problems of poor affinity and poor human comfort, and achieve the effect of improving strength

Inactive Publication Date: 2018-12-28

GUANGZHOU WUYUAN NEW MATERIAL CO LTD

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the defects of the "grain layer" made of chemical materials and poor comfort and affinity to the human body, all kinds of substitute leathers are currently

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

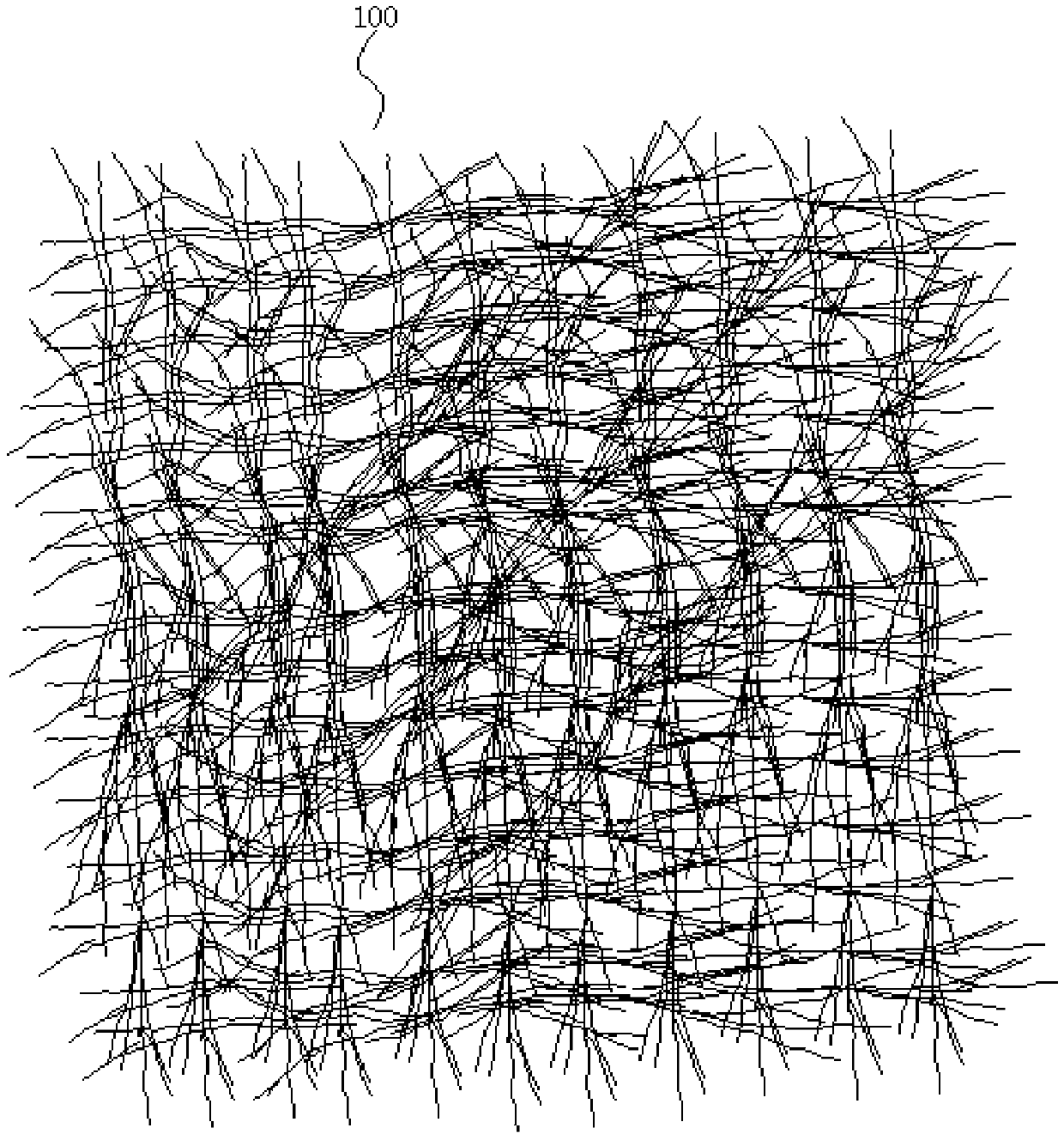

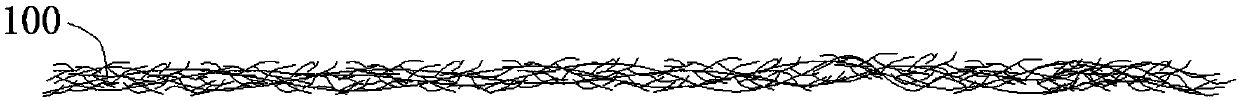

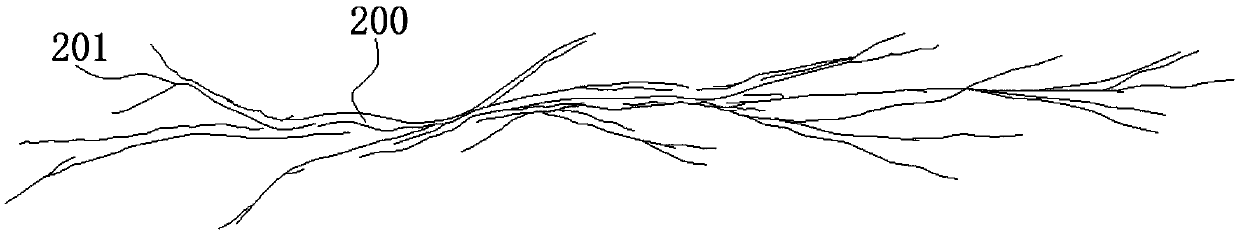

The invention discloses a leather material based on an artificial grain surface layer, the artificial grain surface layer and a processing method of the leather material based on the artificial grainsurface layer. The leather material comprises the artificial grain surface layer and a bottom layer, wherein the artificial grain surface layer comprises a fine collagen fiber bundle, the fine collagen fiber bundle in the artificial grain surface layer and branches of the fine collagen fiber bundle are intertwined mutually, and the fineness of a main body of the fine collagen fiber bundle in the artificial grain surface layer is smaller than that of the main body of fibers in the bottom layer. The processing method comprises the following steps: (1) manufacturing the fine collagen fiber bundle; (2) forming a web by using the manufactured fine collagen fiber bundle; (3) processing the leather material formed by the artificial grain surface layer formed by intertwining the fine collagen fiber bundle and the branches of the fine collagen fiber bundle mutually and the bottom layer combined with the artificial grain surface layer through a spunlace process. In the invention, the leather material is formed by remanufacturing the artificial grain surface layer by using the collagen fiber bundle in leather, so that the performance, structure and appearance of the artificial grain surface layer in the leather material are extremely similar to the grain surface layer of the leather, to improve comfort, affinity, breathability and hygroscopicity of the leather material.

Description

Technical field The invention relates to an artificial grain surface layer processed from slender collagen fiber bundles and a leather material made from the artificial grain surface layer. Background technique Leather is a commonly used product in people's daily life. At present, leather mainly includes real leather and imitation leather. "Real leather" refers to products made of animal real leather. With the development of industry, people have developed many forms of imitation leather. Imitation leather is generally made of cloth made of chemical fiber as the base material, and then PU, PVC or other Resin materials are coated or laminated on one side of the above substrate to make a product that looks like real leather. This type of product is also called: artificial leather, synthetic leather, etc. "Real leather" is a leather with certain acid resistance, alkali resistance, and humidity and heat resistance after a series of physical and chemical processing is carried out f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D06N3/00

CPCD06N3/0011D06N3/0013D06N2209/123D06N2209/141D06N2211/28

Inventor 张立文

Owner GUANGZHOU WUYUAN NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com