Core-spun yarn with collagenous fiber bundles as sheath layer and processing method thereof

A technology of collagen fiber bundles and processing methods, which is applied in the field of yarns, can solve problems such as failure to reach tensile strength, failure to process, and inability to give full play to the excellent properties of collagen fiber bundles, and achieve the goal of improving tensile strength and wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

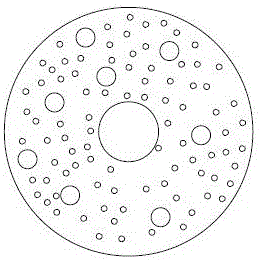

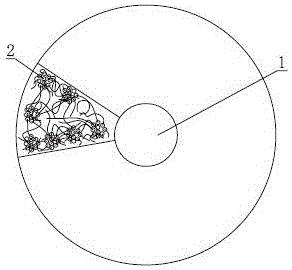

[0059] Such as figure 2 As shown, the core-spun yarn with collagen fiber bundles as the skin layer includes a core yarn 1, and the core yarn 1 is covered with a skin layer formed by twisting collagen fiber bundles.

[0060] The core yarn 1 is single or multiple chemical fiber filaments or textile staple yarns.

[0061] Collagen fiber bundles 2 and their branches in the cortex and adjacent collagen fiber bundles and their branches are interlaced and twisted into a three-dimensional network structure arranged in the axial direction.

[0062] Such as Figure 4 As shown, the collagen fiber bundle 2 is a finer collagen fiber bundle that is split into more than two strands after carding, and the finer collagen fiber bundles form a structure with further branches 22 step by step.

[0063] In this example, the "thinner collagen fiber bundle" described is thinner than the "collagen fiber bundle".

[0064] The processing method of the core-spun yarn with the collagen fiber bundle as...

Embodiment 2

[0075] Such as figure 2 As shown, the core-spun yarn with collagen fiber bundles as the skin layer includes a core yarn 1, and the core yarn 1 is covered with a skin layer formed by twisting collagen fiber bundles.

[0076] The core yarn 1 is single or multiple chemical fiber filaments or textile staple yarns.

[0077] Collagen fiber bundles 2 and their branches in the cortex are intertwined, twisted and covered outside the core yarn.

[0078] Such as Figure 4 As shown, the collagen fiber bundle 2 is a finer collagen fiber bundle that splits into two or more strands after carding, and the finer collagen fiber bundles form a structure with further branches 22 step by step.

[0079] In this embodiment, "collagen fiber bundles 2 and their branches are intertwined with each other" means that the collagen fiber bundles and their branches are intertwined with each other and the adjacent collagen fiber bundles and their branches are intertwined with each other .

[0080] The pr...

Embodiment 3

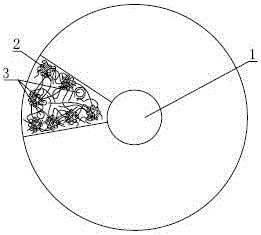

[0091] Such as image 3 As shown, the core-spun yarn with collagen fiber bundles as the skin layer includes a core yarn 1, and the core yarn 1 is covered with a skin layer formed by twisting after 50% collagen fiber bundles and 50% other textile fibers 3 are drawn.

[0092] The core yarn 1 is single or multiple chemical fiber filaments or textile staple yarns.

[0093] Other textile fibers are at least one of natural fibers and chemical fibers.

[0094] Collagen fiber bundles 2 and their branches in the cortex form a three-dimensional network structure arranged in the axial direction by interlacing and twisting with adjacent collagen fiber bundles and their branches. The fibers are interlaced and twisted into a three-dimensional network structure arranged in the axial direction. That is, the collagen fiber bundles and their branches in the cortex are intertwined with the adjacent collagen fiber bundles and their branches, and the collagen fiber bundles and their branches are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com