Modified cinder adsorbent and preparing method and application

An adsorbent and modification technology, applied in chemical instruments and methods, adsorption water/sewage treatment, silicate, etc., can solve environmental burden and other problems, achieve high adsorption efficiency, good effect, and reduce environmental burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

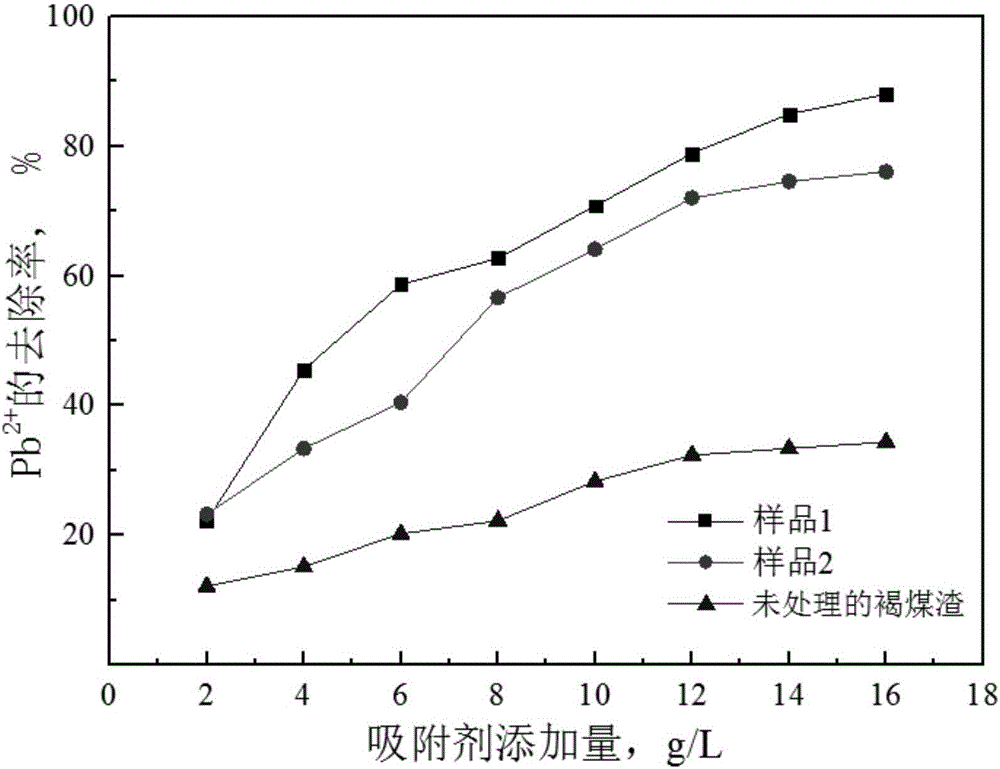

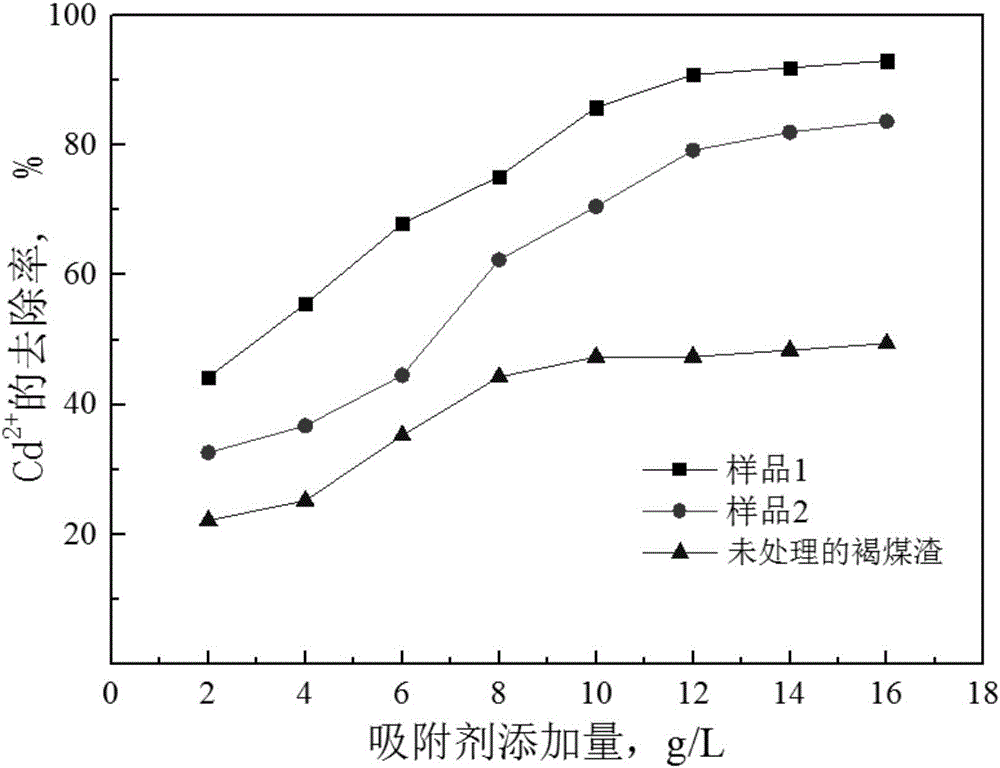

Embodiment 1

[0022] A preparation method of a modified coal slag adsorbent, comprising the steps of:

[0023] 1) The lignite slag is washed with water, dried, mixed with pyrite slag equivalent to 0.1 times the quality of the dried lignite slag, and pulverized; particles between 60-100 mesh are taken;

[0024] 2) According to the ratio of 100g:400mL, immerse the mixture obtained in step 1) in the aqueous hydrochloric acid solution with pH=1, acidify and modify for 16 hours; stir once every 30min during the acidify and modify; filter, recover the filtrate, The solid was washed with water, dried, put into a muffle furnace, and roasted at 450° C. for 50 minutes to obtain a modified cinder adsorbent (sample 1).

Embodiment 2

[0026] A preparation method of a modified coal slag adsorbent, comprising the steps of:

[0027] 1) The lignite slag is washed with water, dried, mixed with pyrite slag equivalent to 0.1 times the quality of the dried lignite slag, and pulverized; particles between 60-100 mesh are taken;

[0028] 2) According to the ratio of 100g:400mL, immerse the mixture obtained in step 1) in the sulfuric acid aqueous solution with pH=1, acidify and modify for 16h; stir once every 30min during the acidify and modify; filter, recover the filtrate, The solid was washed with water, dried, put into a muffle furnace, and roasted at 450°C for 50 minutes to obtain a modified cinder adsorbent (sample 2)

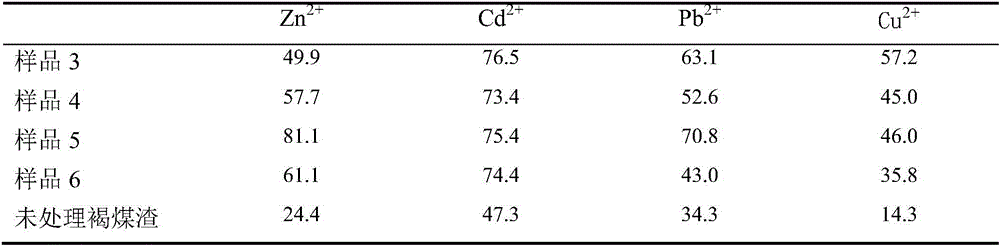

Embodiment 3

[0030] A preparation method of a modified coal slag adsorbent, comprising the steps of:

[0031] 1) washing lignite slag with water, drying, mixing with pyrite slag equivalent to 0.15 times the quality of dried lignite slag, pulverizing, and getting particles between 50-70 mesh;

[0032] 2) According to the ratio of 100g: 300mL, soak the mixture obtained in step 1) in the aqueous solution of nitric acid with pH=1.5, acidify and modify it for 20h; stir once every 20min; filter, recover the filtrate, wash the solid with water, dry, put into a muffle furnace and roasted at 500°C for 30 minutes to obtain a modified coal slag adsorbent. (sample 3)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com