Multi-layer multi-chip fan-out structure and manufacturing method

A multi-chip and die technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as chip shift and low alignment accuracy, and achieve optimized package size, compact package size, and low price Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific drawings and embodiments.

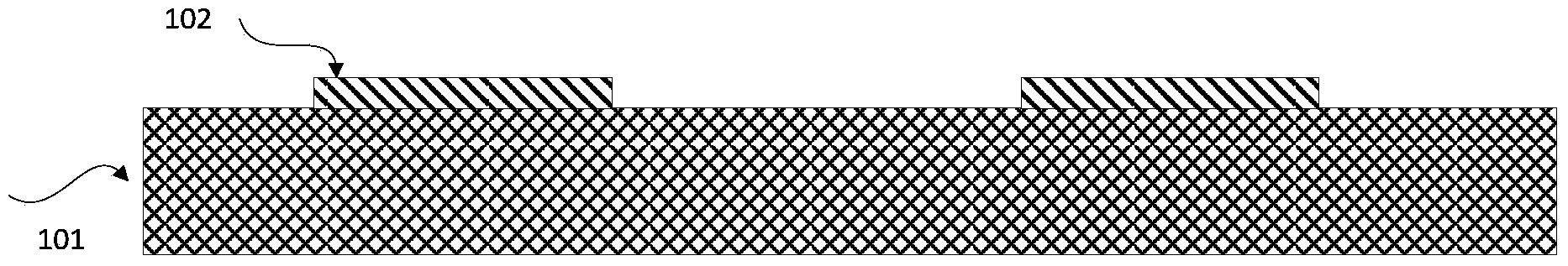

[0043] Such as Figure 11 Shown:

[0044] A multi-layer multi-chip fan-out structure, including a carrier board 101, on which a plurality of stacked package sub-bodies are arranged; each package sub-body is packaged with at least one die 201; in each package sub-body Among them, one or more dies 201 are covered by the dielectric material of the dielectric layer 103, and the dies 201 are mounted on the metal pad 102 in a face-up manner; There is an RDL layer 104; the solder pad on the front side of the die 201 is electrically connected to the RDL layer 104 of the package sub-body where the die 201 is located through the first interconnection hole 202'.

[0045] An insulating layer 105 is provided between adjacent package sub-bodies, and the RDL layers 104 of adjacent package sub-bodies are electrically connected through the second interconnection hole 203' bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com