Preparation process of cast steel material capable of resisting high temperature of 620 DEG C

A preparation process, high temperature resistance technology, applied in the improvement of process efficiency, furnace type, furnace and other directions, can solve the problems of harsh specifications, large investment in infrastructure costs, complex chemical composition, etc., to improve cleanliness, effective process means and saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

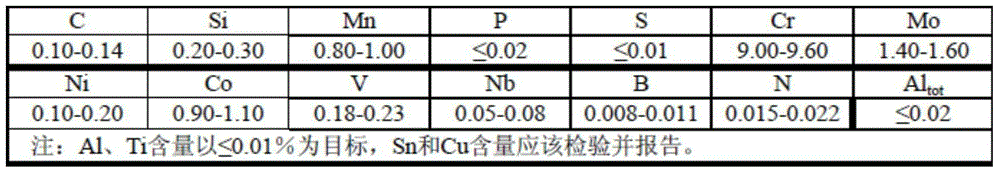

[0062] Products in the following examples

[0063] material as target ingredient

[0064]

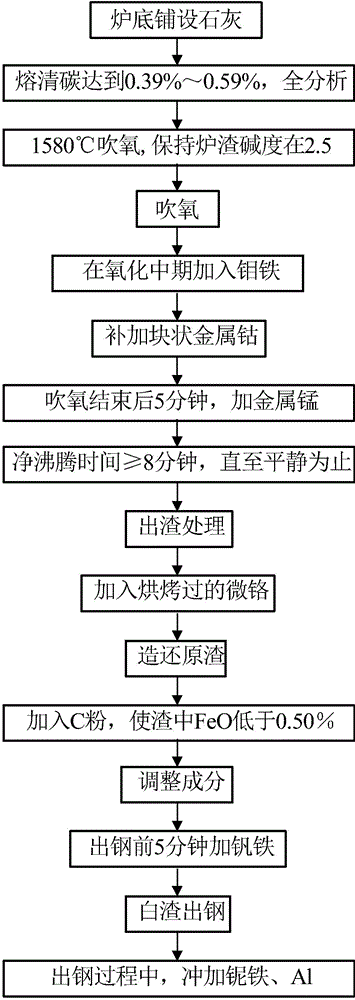

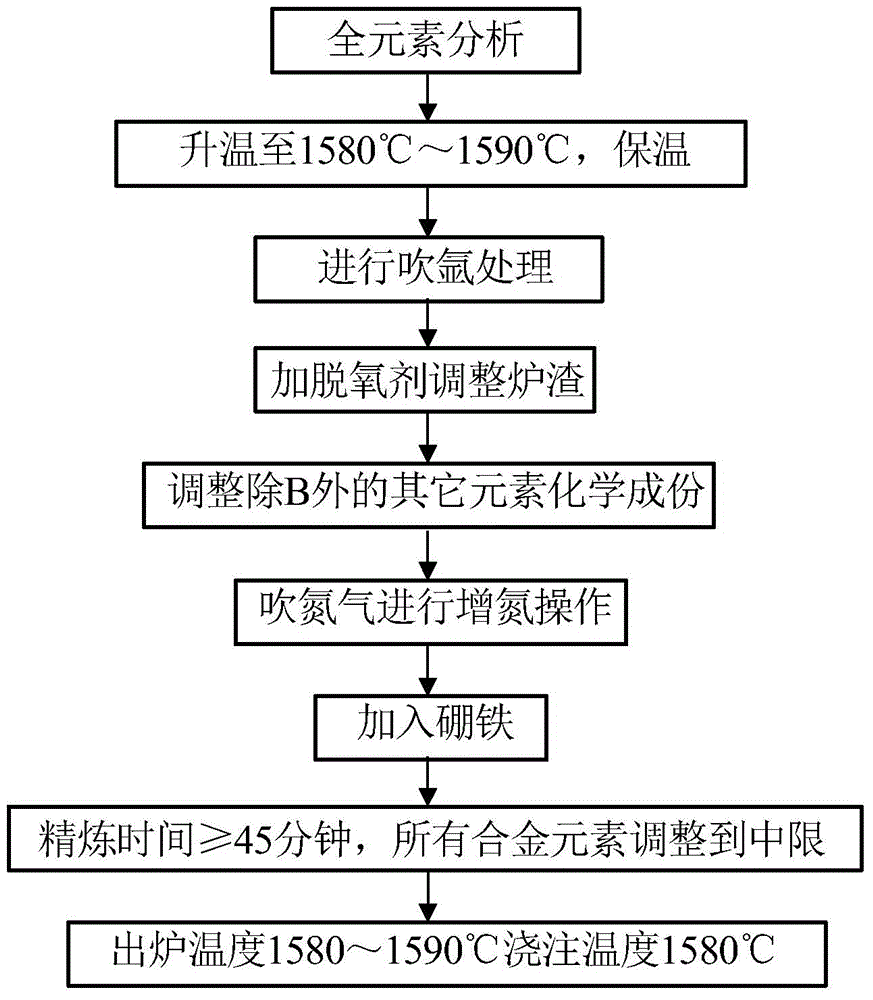

[0065] A preparation process of a cast steel material with a high temperature resistance of 620 degrees, the cast steel material is ZG13Cr9Mo2Co1NiVNbNB, the preparation process includes an electric arc furnace melting process and a ladle refining furnace melting process, and is characterized in that:

[0066] The described electric arc furnace smelting process comprises:

[0067] a, Lime is laid on the bottom of the furnace before the charge of low-sulfur phosphorus-carbon steel plate is fed;

[0068] b. In order to ensure the amount of decarburization, waste electrode blocks are added along with the furnace charge, and when the molten carbon reaches the range of 0.39% to 0.59%, all chemical elements are fully analyzed;

[0069] c. When the temperature of the molten pool reaches 1580°C, oxygen blowing is started, the furnace body is tilted forward, and the oxidized slag is dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com