Composite fluorine-free slag modifier

A technology of slag adjusting agent and weight ratio, which is applied in the field of compound fluorine-free slag adjusting agent, can solve the problems of not being able to form mud guns, strong erosion force and scouring force, etc., to improve slag viscosity, good air permeability, and solve fluorine pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

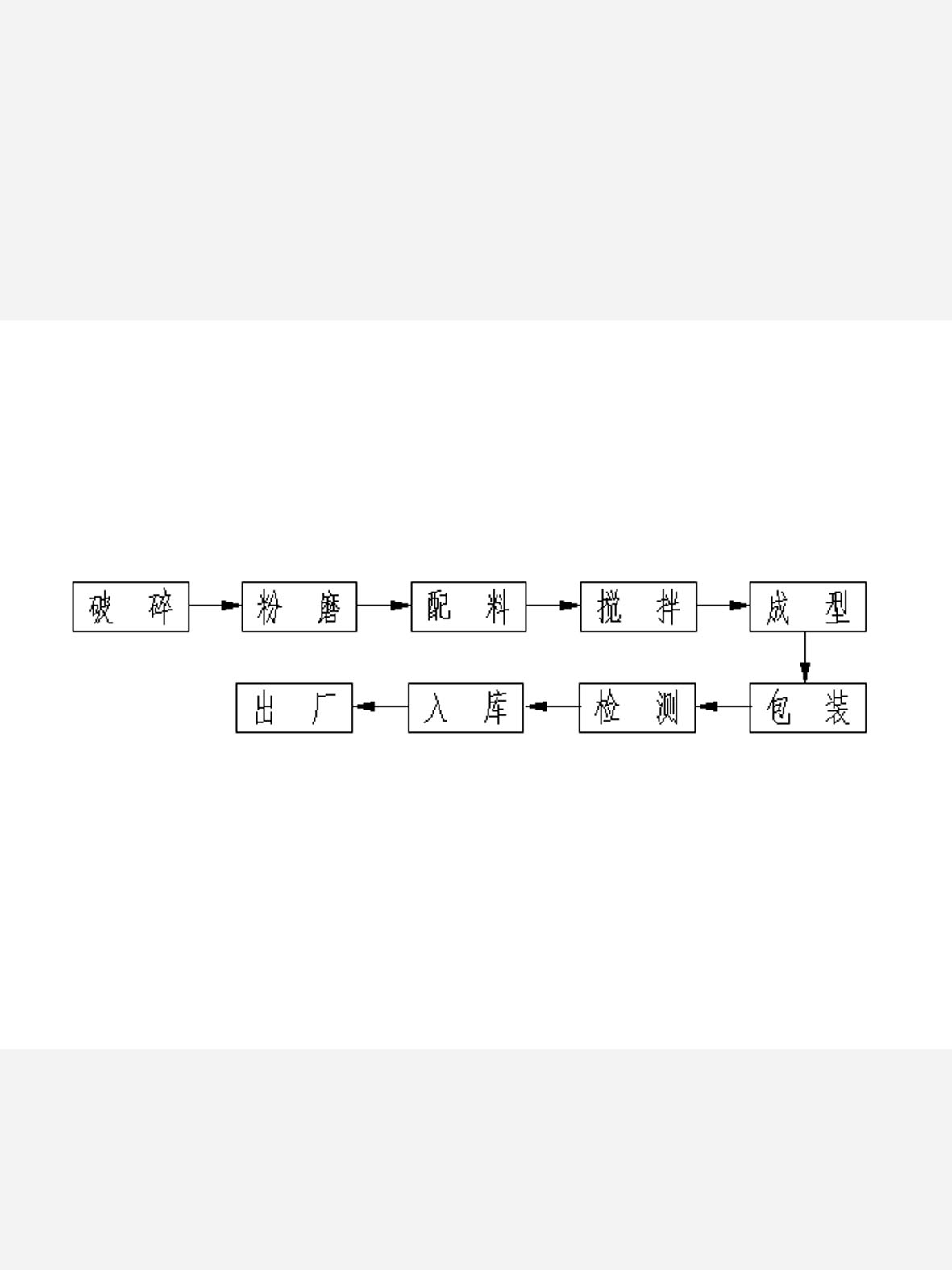

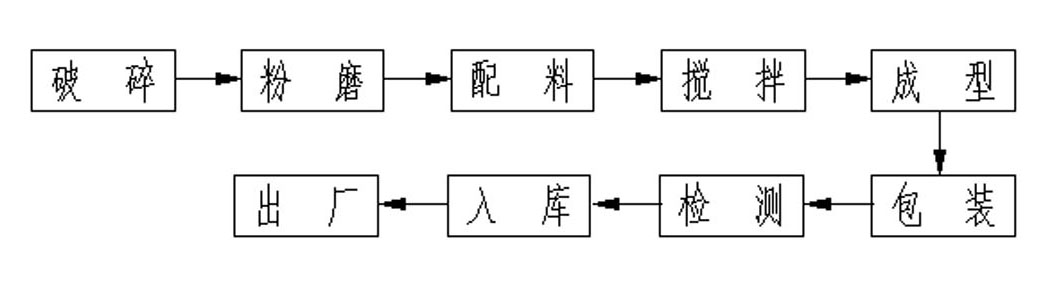

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0024] A compound fluorine-free slagging agent, its chemical composition and weight ratio are: SiO 2 8-24, CaO4-14, Al 2 o 3 20-28, Fe 2 o 3 20-30 , MgO3-6, MnO3-8, the particle size of the composite fluorine-free slag control agent is 34x24x12 mm 3 ; The melting point of the composite fluorine-free slagging agent is ≤1300°C.

[0025] see figure 1 , a manufacturing method of a composite fluorine-free slagging agent, through crushing and grinding, Fe 2 o 3 ≥30%, Al 2 o 3 ≥35% bauxite is processed into 40-100 mesh granules, then Iceland stone with CaO>99% and manganese ore with MnO≥20% are added for batching, after mixing evenly, dry press into granules of 34x24x12 mm 3 Formed products are then packaged, inspected and put into storage, and finally leave the factory.

[0026] Composite fluorine-free slagging agent is a neutral material with a particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com