Ruthenium-based adsorbent for deeply removing thiophene of benzene as well as preparation method and application of ruthenium-based adsorbent

A deep adsorption, adsorbent technology, applied in adsorption purification/separation, chemical instruments and methods, other chemical processes, etc., can solve the problem that the adsorption sulfur capacity cannot be further improved, and achieve good application prospects, easy industrialization, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

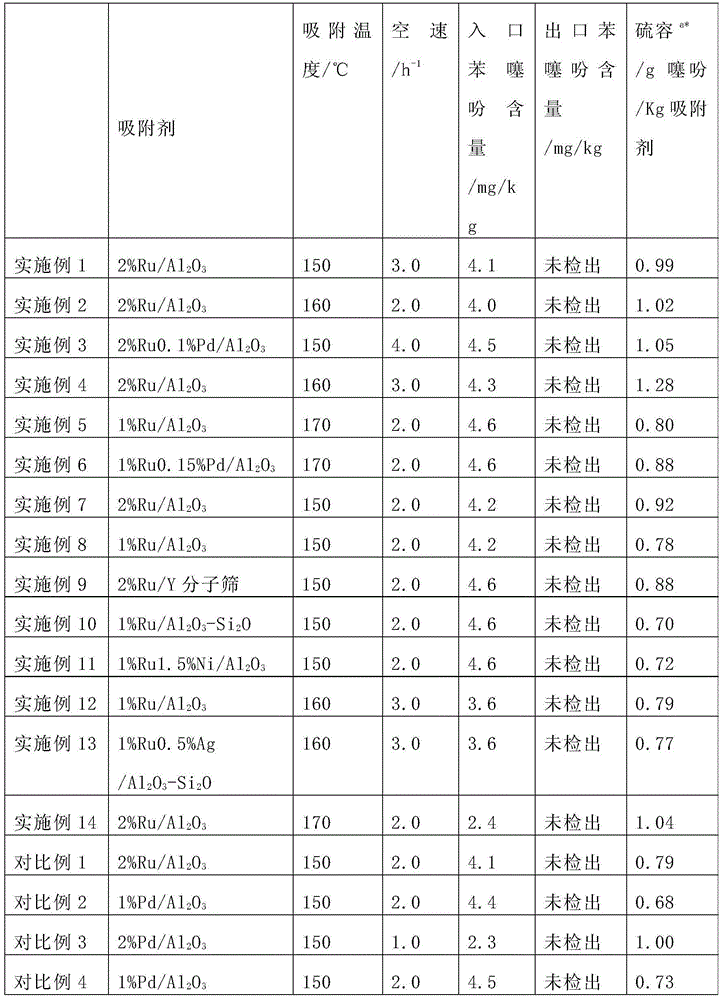

Examples

Embodiment 1

[0100] (1) Carrier pretreatment

[0101] Accurately weigh the bulk density to 0.60g / ml and the specific surface area to 110m 2 / g, the pore volume is 0.6ml / g, the diameter is 500g of the spherical alumina carrier of 2.0mm, is placed in the 5000mL beaker, adds 3wt% boric acid-methanol aqueous solution 1500mL, the volume ratio of methanol and water is 1:5. Immerse at a temperature of 50°C for 4 hours, take it out and dry it at 80°C for 8 hours, bake it in an air atmosphere at 350°C for 4 hours, and cool to obtain a treated carrier.

[0102] (2) Adsorbent preparation

[0103] Accurately weigh RuCl with a Ru content of 37.0wt% 3 .nH 2 O 5.41g, put in 1000mL beaker, add 20mL deionized water to dissolve, dilute to 120ml with 1.0wt% PVP-K30 aqueous solution, adjust solution pH value to 2.0 with 5wt% sodium hydroxide aqueous solution, add 100g processed carrier , soaked at a temperature of 30°C for 18 hours. Add 500mL of 10wt% sodium hydroxide aqueous solution, and invert and pre...

Embodiment 2

[0105] (1) Carrier pretreatment

[0106] Prepared supports were prepared as described in Example 1.

[0107] (2) Adsorbent preparation

[0108] Accurately weigh RuCl with a Ru content of 37.0wt% 3 .nH 2 O 5.41g, be placed in the 1000mL beaker, add 20mL deionized water and dissolve, adjust solution pH value to 2.0 with 2wt% sodium hydroxide aqueous solution, be diluted to 120 milliliters with 0.5wt% PVP-K30 aqueous solution, add 100g as embodiment 1 The treated carrier was soaked at a temperature of 60° C. for 6 hours. Add 500mL of 6wt% sodium hydroxide aqueous solution, and invert and precipitate at 50°C for 4 hours. At a temperature of 80°C, slowly add 200mL of 6wt% sodium borohydride aqueous solution (containing 0.1wt% sodium hydroxide), and reduce for 1 hour. After the reduction, rinse with 40°C deionized water until the washing liquid does not contain chloride ions (Aqueous solution of silver nitrate is detected), placed in a vacuum oven for 8 hours at 110°C and dried...

Embodiment 3

[0110] (1) Carrier pretreatment

[0111] Accurately weigh the bulk density to 0.70g / ml and the specific surface area to 180m 2 / g, the pore volume is 0.75ml / g, the spherical alumina support 500g that diameter is 1.3mm is placed in the 5000mL beaker, adds 5wt% boric acid-ethanol aqueous solution 2000mL, the volume ratio of ethanol and water is 1:4, in Immerse at a temperature of 70°C for 4 hours, take it out and dry it at 100°C for 8 hours, bake it in an air atmosphere at 400°C for 6 hours, and cool to obtain a treated carrier.

[0112] (2) Adsorbent preparation

[0113] Accurately weigh RuCl with a Ru content of 37.0wt% 3 .nH 2 O 5.41g, put in 1000mL beaker, add 20mL deionized water to dissolve, add 2ml 1:1 hydrochloric acid to dissolve Pd content 59.0wt%PdCl 2 0.169g, adjust the pH value of the solution to 1.5 with 5wt% sodium bicarbonate aqueous solution, dilute to 150 milliliters with 1.0wt% PEG-600 aqueous solution, add 100g processed carrier, and soak for 12 hours at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com