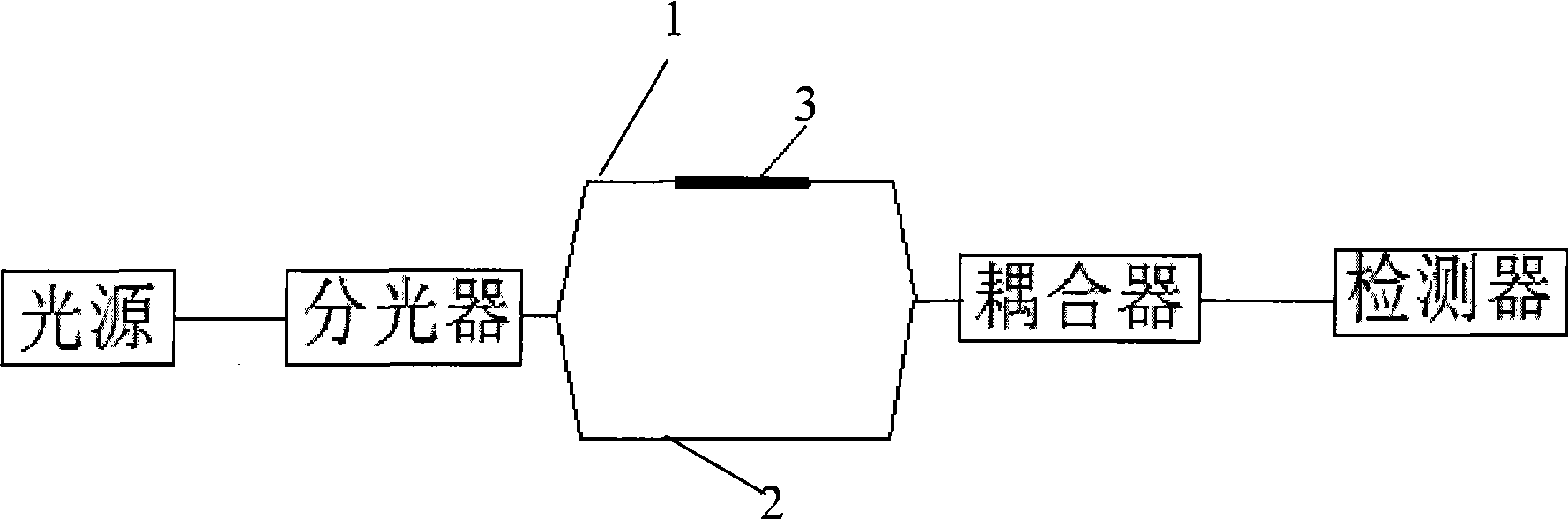

Hydrogen sensor and pd film hydrogen sensing system

A sensor and hydrogen technology, applied in the field of sensor measurement, can solve the problems such as the influence of ambient temperature disturbance and the difficulty of achieving high-resolution stable measurement, and achieve the effect of overcoming the influence of ambient temperature disturbance, obvious price advantage, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

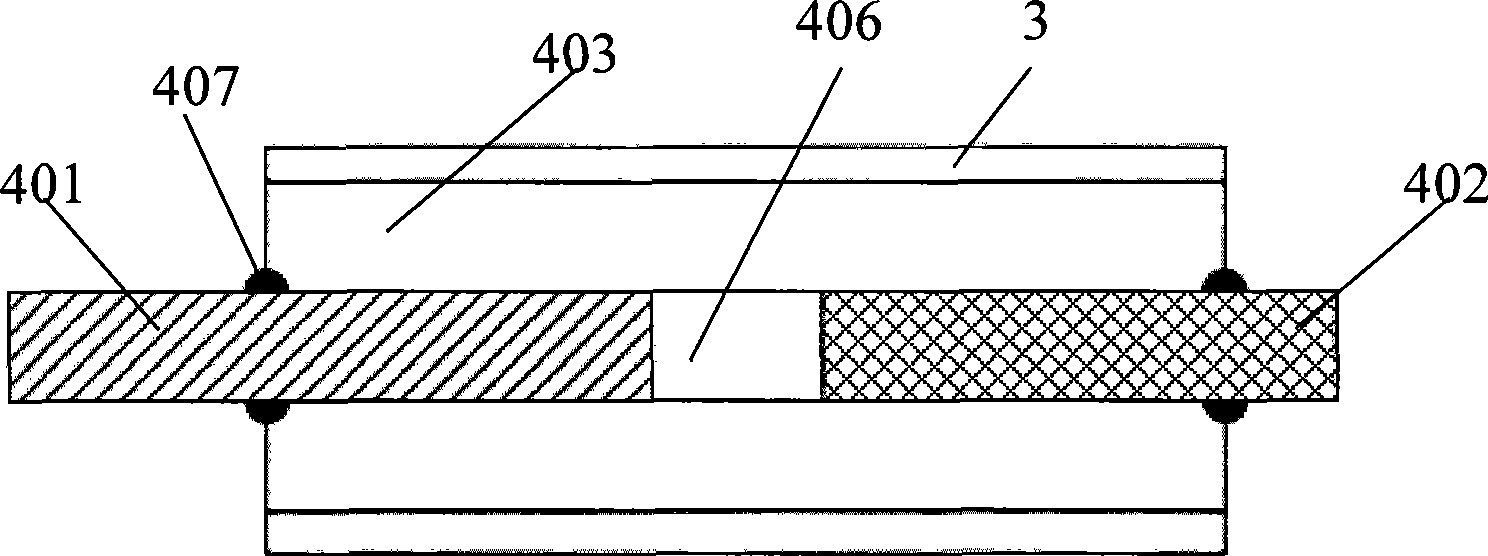

[0047] The hollow tube in this embodiment can adopt a capillary tube, wherein a preferred embodiment, such as figure 2 As shown, the hydrogen sensor includes: an introduction optical fiber 401, a reflection optical fiber 402 and a quartz capillary 403, the surface of the quartz capillary 403 is coated with a palladium or palladium alloy film 3 to realize the sensitivity of the quartz capillary 403 to hydrogen, and an introduction optical fiber with a good vertical end face 401 and reflective optical fiber 402 are put into the quartz capillary 403 together from both ends, using CO 2 Laser or epoxy fixes the two optical fibers together with the quartz capillary 403, such as figure 2 As shown in the fixed point 407, the two opposite fiber end faces of the leading optical fiber 401 and the reflecting fiber 402 together with the lumen of the quartz capillary 403 form an interference cavity 406, and the outer diameters of the leading optical fiber 401 and the reflecting fiber 402 ...

Embodiment 2

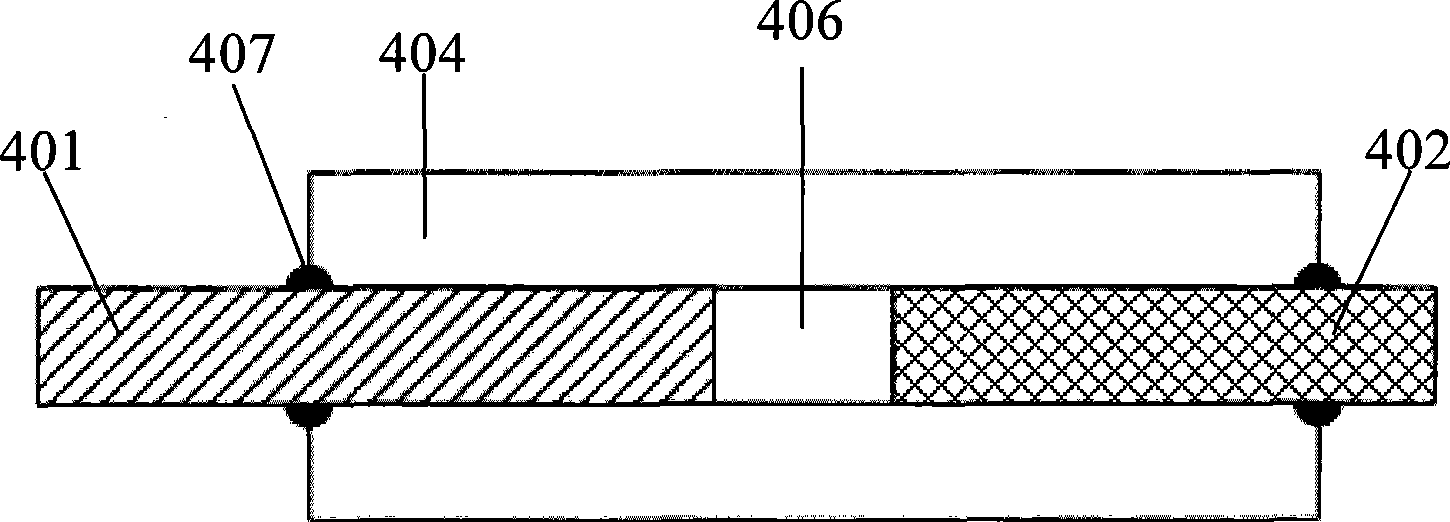

[0050] like image 3 It is a structural diagram of another embodiment of the hydrogen sensor, and its structure is basically the same as that using a quartz capillary 403, the difference is that the capillary is specifically a palladium or palladium alloy capillary 404, which is sensitive to hydrogen, because the palladium or palladium alloy capillary 404 The surface itself has a palladium or palladium alloy film 3, therefore, the step of needing to coat a layer of palladium or palladium alloy film in Example 1 is omitted during manufacture.

Embodiment 3

[0052] The hydrogen sensor based on EFPI of the present invention is specifically based on the hollow-core photonic crystal fiber method-Perco interference sensor, such as Figure 4 As shown, a section of hollow-core photonic crystal fiber 405 (PCF) is used as a Fabry-Perot cavity (interference cavity), and the leading optical fiber 401 and the reflecting optical fiber 402 are both single-mode optical fibers. The hollow-core photonic crystal fiber 405 is fused with two single-mode fibers, and the two opposite end faces of the single-mode fiber at the fusion joint of the hollow-core photonic crystal fiber 405 respectively form two reflecting surfaces of the Fabry-Perot cavity. The surface of the hollow-core photonic crystal fiber 405 is coated with a certain thickness of palladium or palladium alloy film 3 to realize the sensitivity to hydrogen. In this embodiment, a certain thickness of palladium or palladium alloy film 3 is plated on the surface of the hollow-core photonic cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com