Device and method for measuring magnetism of permanent magnet material at high temperature

A permanent magnet material and magnetic technology, which is applied in the field of high-temperature measurement of the magnetism of permanent magnet materials, can solve the problems of low energy, slow magnet heating speed, and affecting measurement results, and achieve the effect of high energy and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

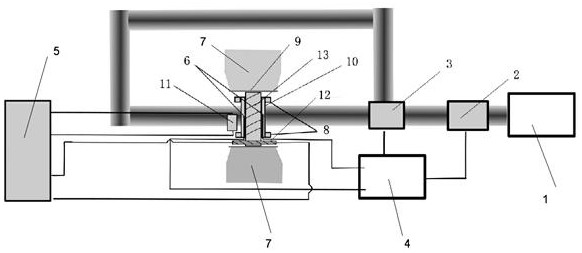

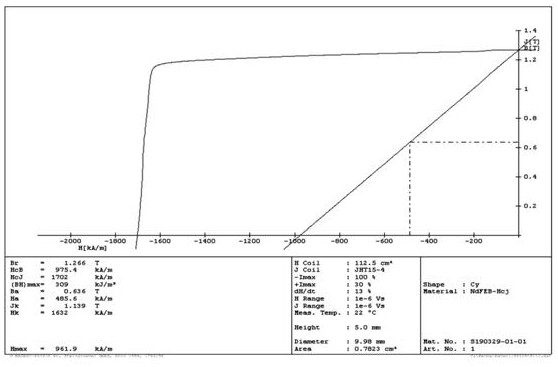

[0051] Taking NdFeB permanent magnet as sample 13, measure sample 13 at 22 o C (room temperature), 100 o C, 130 o C and 150 o At C, the magnetic properties of the NdFeB permanent magnet: first cut the sample 13 into a block magnet with a size of 5×5×5 mm; the specific measurement steps are as follows:

[0052] 1. Use a magnetic punching machine to punch sample 13 to saturation at 9T;

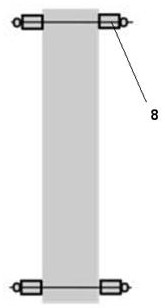

[0053] 2. Fix the two heat-absorbing sheets 10 on the front and rear surfaces of the sample 13 respectively, fix them with the clamp 8, place the sample 13 between the two electromagnet pole heads 7, adjust the distance between the electromagnet pole heads 7, and use the electromagnetic The iron pole 7 compresses the sample 13;

[0054] 3. Preferably use a femtosecond pulse laser with a wavelength of 800-850nm and a frequency of 76MHz. Adjust the laser beam so that two beams of laser light are irradiated on the front and rear surfaces of the sample 13. The spot diameter is 4mm and the laser ...

Embodiment 2

[0061] Take samarium cobalt permanent magnet as sample 13: measure sample 13 at 500 o At C, the magnetic properties of the samarium-cobalt permanent magnet: first cut the sample 13 into a block magnet with a size of 5×5×10 mm, and the specific measurement steps are as follows:

[0062] 1. Use a magnetic punching machine to punch sample 13 to saturation at 7T;

[0063] 2. Fix the two heat-absorbing sheets 10 on the front and rear surfaces of the sample 13 respectively, fix them with the clamp 8, place the sample 13 between the two electromagnet pole heads 7, adjust the distance between the electromagnet pole heads 7, and use the electromagnetic The iron pole 7 compresses the sample 13;

[0064] 3. Preferably use a continuous laser, adjust the laser beam so that two beams of laser light are irradiated on the front and rear surfaces of the sample 13, the spot diameter is 4 mm, and the laser intensity is 100 mW. The temperature sensor 6 on the heat absorbing sheet 10 is used to m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com