Diamond polishing film as well as preparation method and application thereof

A polishing film and diamond technology, which is used in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems that the polishing film cannot meet the processing requirements of optical fiber connectors, the service life of the polishing film is reduced, and the product defect rate is increased. , to achieve the effect of improving self-sharpening, improving yield and service life, and improving polishing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

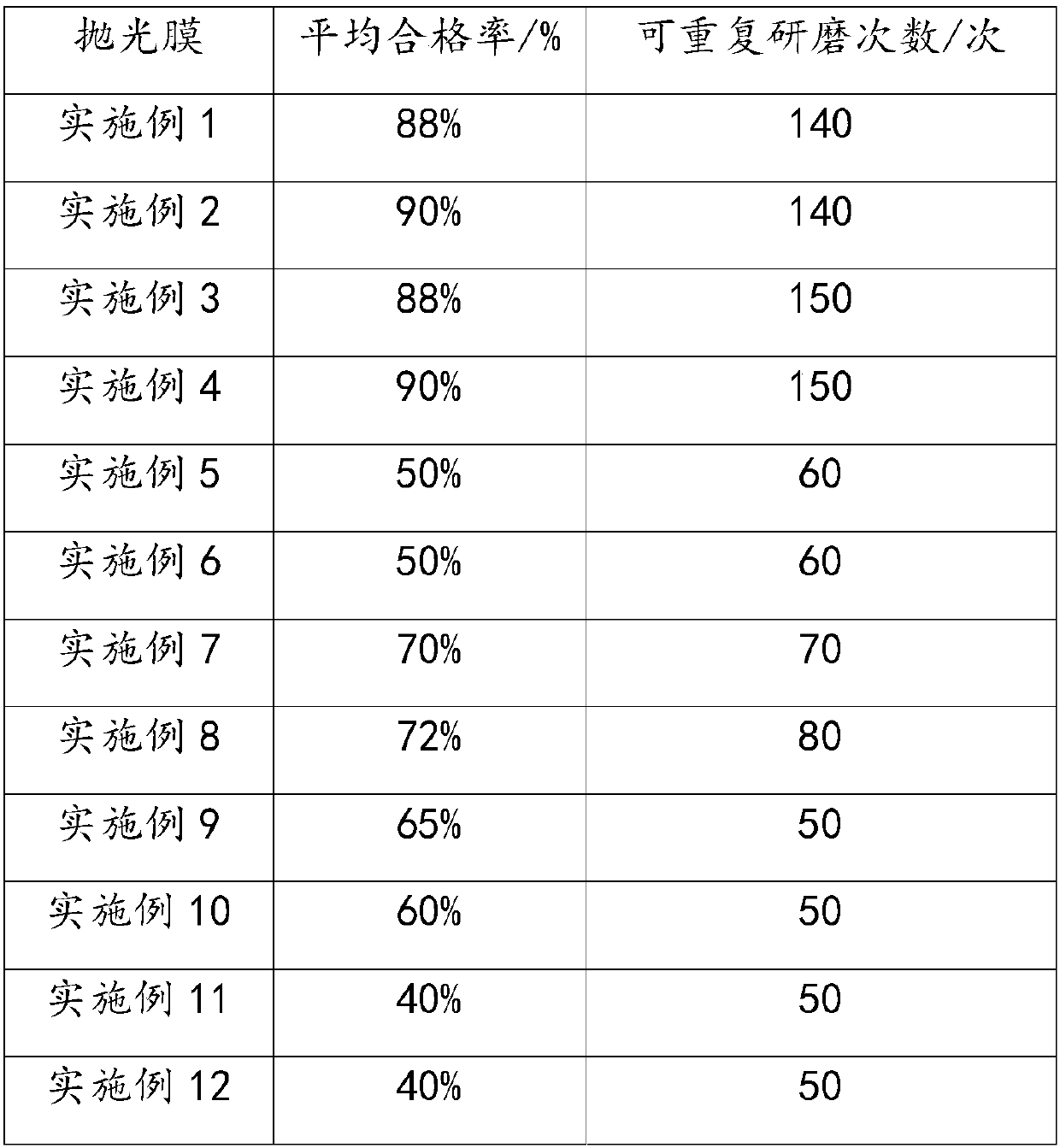

Examples

Embodiment 1

[0062] The preparation method of the diamond polishing film of the present embodiment, comprises the steps:

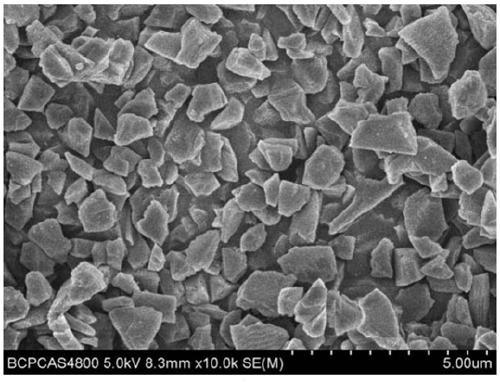

[0063] (1) Get D50=0.9 μm artificial single crystal diamond micropowder 500g, standby; In the mixed solvent (mass ratio is ethanol:water=4:1) of 500g ethanol and water, add silane coupling agent 2.5g, obtain silane Add the above-mentioned diamond micropowder to the coupling agent solution to obtain a mixed solution; stir the mixed solution at 70°C for 4h, centrifuge at 3500rpm for 3min for centrifugal classification, collect the precipitate, dry it, and obtain the coupled diamond micropowder; Surface morphology such as figure 1 shown;

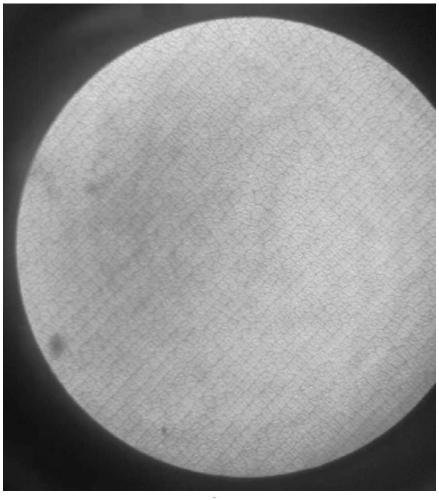

[0064] (2) Add 700g of mixed adhesive with a solid content of 25% to the diamond micropowder of coupling treatment, then add 300g of mixed solvent of butanone, ethyl acetate and toluene with a mass ratio of 1:1:1, and add nano ceramics 5g of powder stiffening agent is fully dispersed by ball mill or ultrasonic disperser to obtain a sl...

Embodiment 2

[0068] The preparation method of the diamond polishing film of the present embodiment, comprises the steps:

[0069] (1) Get 500g of artificial single crystal diamond micropowder with D50=1.1μm, set aside; in the mixed solvent of 500g ethanol and water (mass ratio is ethanol:water=4:1), add 5g of silane coupling agent, obtain silane coupling agent Add the above-mentioned diamond powder to the coupling agent solution to obtain a mixed solution; stir the mixed solution at 70°C for 4 hours, and centrifuge at a speed of 3500 rpm for 3 minutes to obtain a coupling-treated diamond powder;

[0070] (2) Add 600g of mixed adhesive with a solid content of 30% to the diamond micropowder of coupling treatment, then add 400g of mixed solvent of butanone, ethyl acetate and toluene with a mass ratio of 1:1:2, and add nano ceramics 10g of powder stiffening agent is fully dispersed by a ball mill to obtain a slurry, and 80g of a polyurethane curing agent is added to the slurry to obtain a coat...

Embodiment 3

[0074] The preparation method of the diamond polishing film of the present embodiment, comprises the steps:

[0075] (1) Take 500g of artificial single crystal diamond micropowder with D50=1.0 μm, and set aside; in the mixed solvent of 500g ethanol and water (mass ratio is ethanol:water=4:1), add 10g of silane coupling agent to obtain silane coupling agent Add the above-mentioned diamond powder to the coupling agent solution to obtain a mixed solution; stir the mixed solution at 70°C for 4 hours, and centrifuge at a speed of 3500 rpm for 3 minutes to obtain a coupling-treated diamond powder;

[0076] (2) Add 500g of mixed adhesive with a solid content of 40% to the diamond micropowder of coupling treatment, then add 200g of mixed solvent of butanone, ethyl acetate and toluene with a mass ratio of 1:2:1, and add nano ceramics 15g of powder stiffening agent, after being fully dispersed by a ball mill, a slurry is obtained, and 70g of a polyurethane curing agent is added to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com