Ag-Cu in-situ fiber composite material and preparation method thereof

A composite material and fibrous technology, applied in the field of Ag-Cu in-situ fiber composite material and its preparation, can solve the problems of insufficient strength and electrical conductivity, low strength and hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

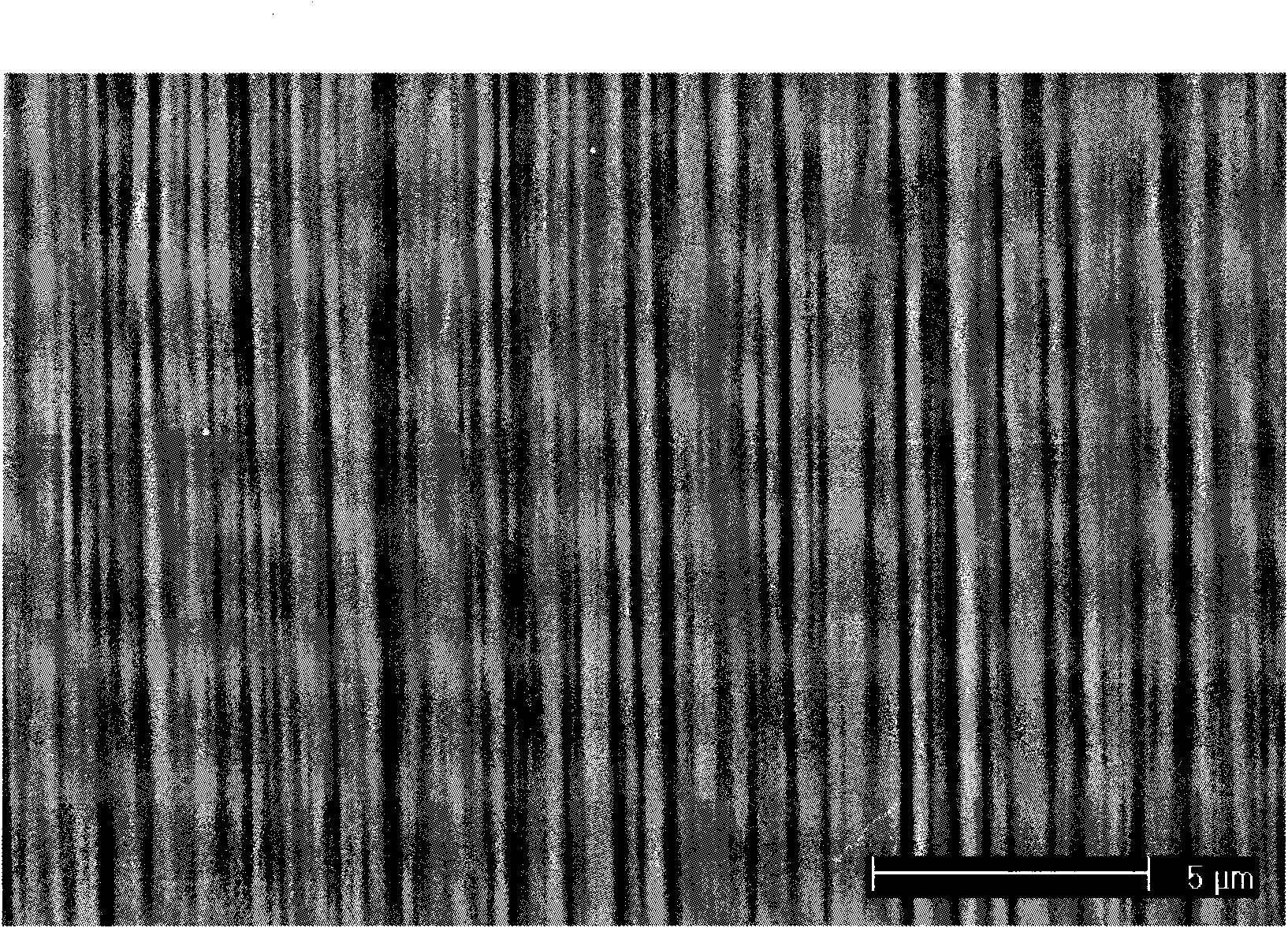

Image

Examples

Embodiment 1

[0025] Example 1: Ag-Cu composite material containing 10% Cu by mass fraction. Melted in an intermediate frequency furnace under vacuum, cast into an ingot with a diameter of 80mm in an argon protective atmosphere, annealed at 680°C / 4h and then extruded to 28mm, and cold drawn for multiple passes at room temperature. During the drawing process, 200°C / 1h intermediate heat treatment is carried out at η=2.8. When the deformation is η=8.0, the properties of the obtained wire are: tensile strength is 985MPa, and electrical conductivity is 63%IACS.

Embodiment 2

[0026] Example 2: Ag-Cu composite material containing 10% Cu by mass fraction. Melted in an intermediate frequency furnace under vacuum, cast into an ingot with a diameter of 80mm in an argon protective atmosphere, annealed at 680°C / 4h and then extruded to 28mm, and cold drawn for multiple passes at room temperature. During the drawing process, 300°C / 1h intermediate heat treatment is carried out at η = 2.8. When the deformation is η = 8.0, the properties of the obtained wire are: tensile strength is 800MPa, and electrical conductivity is 72% IACS.

Embodiment 3

[0027] Example 3: Ag-Cu composite material containing 10% Cu by mass fraction. Melted in an intermediate frequency furnace under vacuum, cast into an ingot with a diameter of 80mm in an argon protective atmosphere, annealed at 680°C / 4h and then extruded to 28mm, and cold drawn for multiple passes at room temperature. During the pulling process, 200°C / 1h intermediate heat treatment is carried out at η=2.8, and when the deformation is η=8.0, it is subjected to 200°C / 0.5h stabilization heat treatment. The properties of the obtained wire are: tensile strength 910MPa , the conductivity is 73% IACS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com