Solid solution and aging treatment method for cooperating Cu-Ag alloy cold drawing processing

An aging treatment and cold drawing technology, applied in the field of copper-based alloy preparation, can solve problems such as heat treatment and deformation processing of the original structure, which have not been involved, and achieve convenient strength and electrical conductivity, high strength and good electrical conductivity matching level , the effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Pickling with a mass fraction of 7% pure silver and 93% electrolytic copper and fully cleaning and drying;

[0026] Put the raw material in a vacuum induction furnace, melt it under the atmospheric pressure of less than 0.1Pa and let it stand for degassing, then fill the furnace with Ar gas to 30kPa, after fully electromagnetic stirring, let it stand for 2 to 3 minutes and cast it into a Φ23×180mm ingot ;

[0027] The ingot was heated and kept in three stages under the protection of reducing atmosphere, the heating rate was 10, 5 and 1°C / min, the heating temperature was 720, 740 and 775°C, and the holding time was 4, 4 and 8 hours respectively. After quenching water cooling;

[0028] Place the solid solution ingot in a furnace at 350°C for 128 hours and then cool with the furnace;

[0029] After turning to remove the surface defects of the ingot, it is drawn in multiple passes at room temperature. When the deformation degree η<3.0, the average deformation degree of t...

Embodiment 2

[0031] Pickling with a mass fraction of 9% pure silver and 91% electrolytic copper was fully cleaned and then dried.

[0032] The ingot smelting and casting process are the same as in Example 1.

[0033] The solid solution process and heating rate are the same as in Example 1. The solid solution heating temperature is 720, 740 and 770°C respectively; the holding time is 2, 2 and 4 hours respectively, and the water is quenched and cooled after holding the heat;

[0034] Place the solid solution ingot in a furnace at 450°C for 32 hours and then cool with the furnace;

[0035] The drawing process is the same as in Example 1.

Embodiment 3

[0037] Pickling with mass fraction of 12% pure silver and 88% electrolytic copper and fully cleaning and drying;

[0038] Ingot smelting and pouring process are the same as embodiment 1;

[0039] The solid solution process and heating rate are the same as in Example 1. The solid solution heating temperature is 720, 740 and 760°C respectively; the holding time is 2, 4 and 8 hours respectively, and the water is quenched and cooled after holding the heat;

[0040] Place the solid solution ingot in a furnace at 550°C for 1 hour and then cool with the furnace;

[0041] The drawing process is the same as in Example 1.

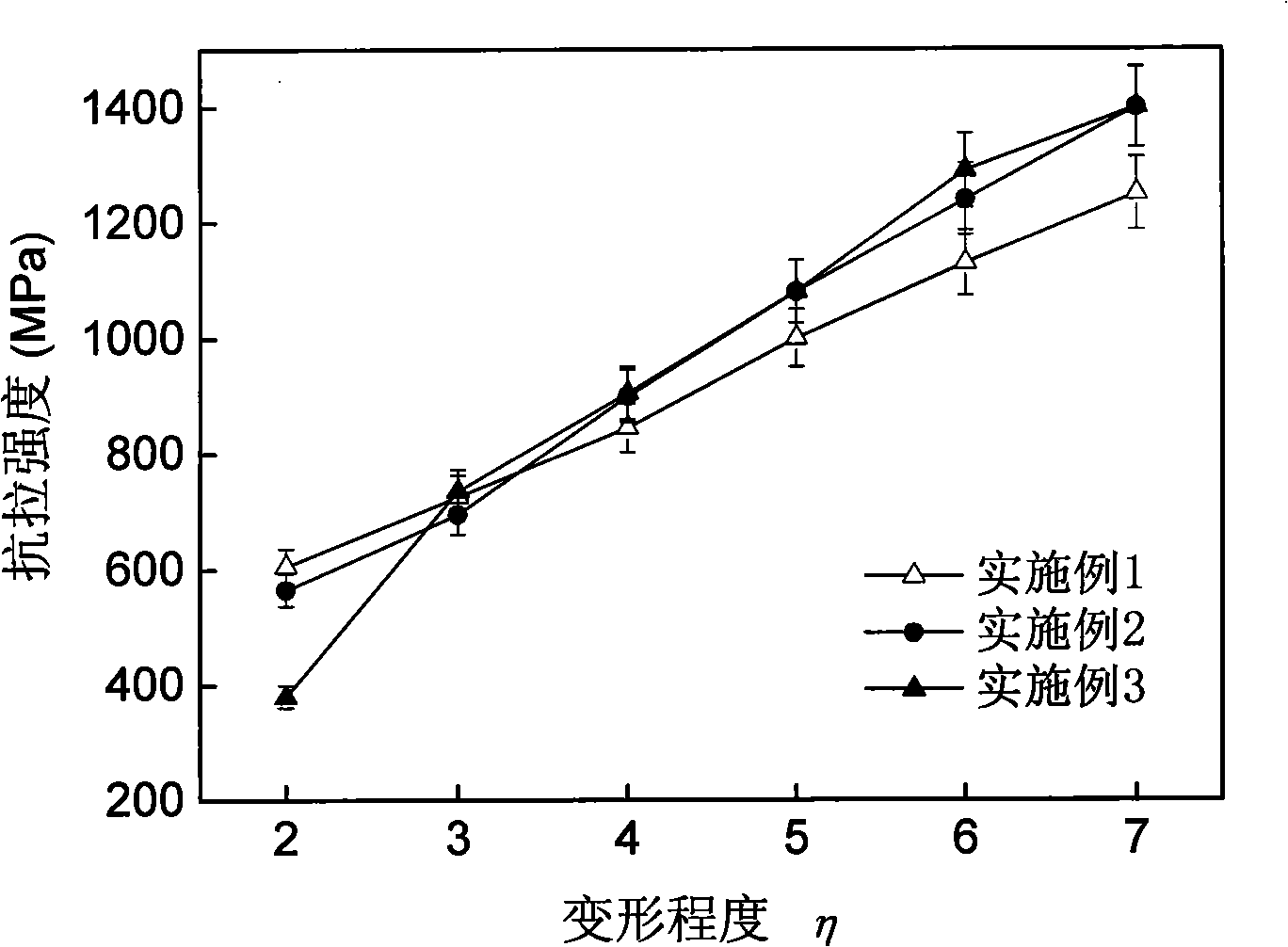

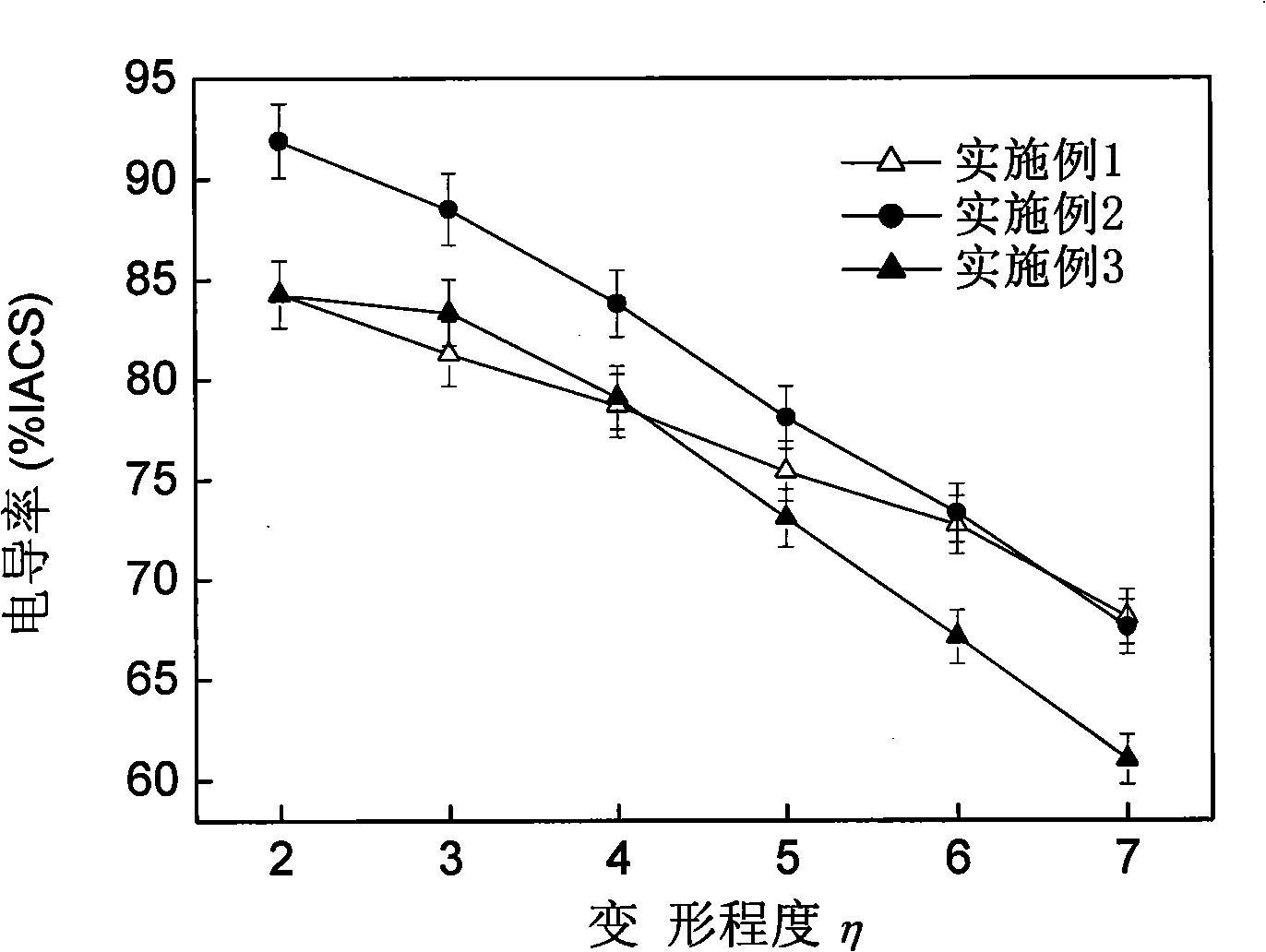

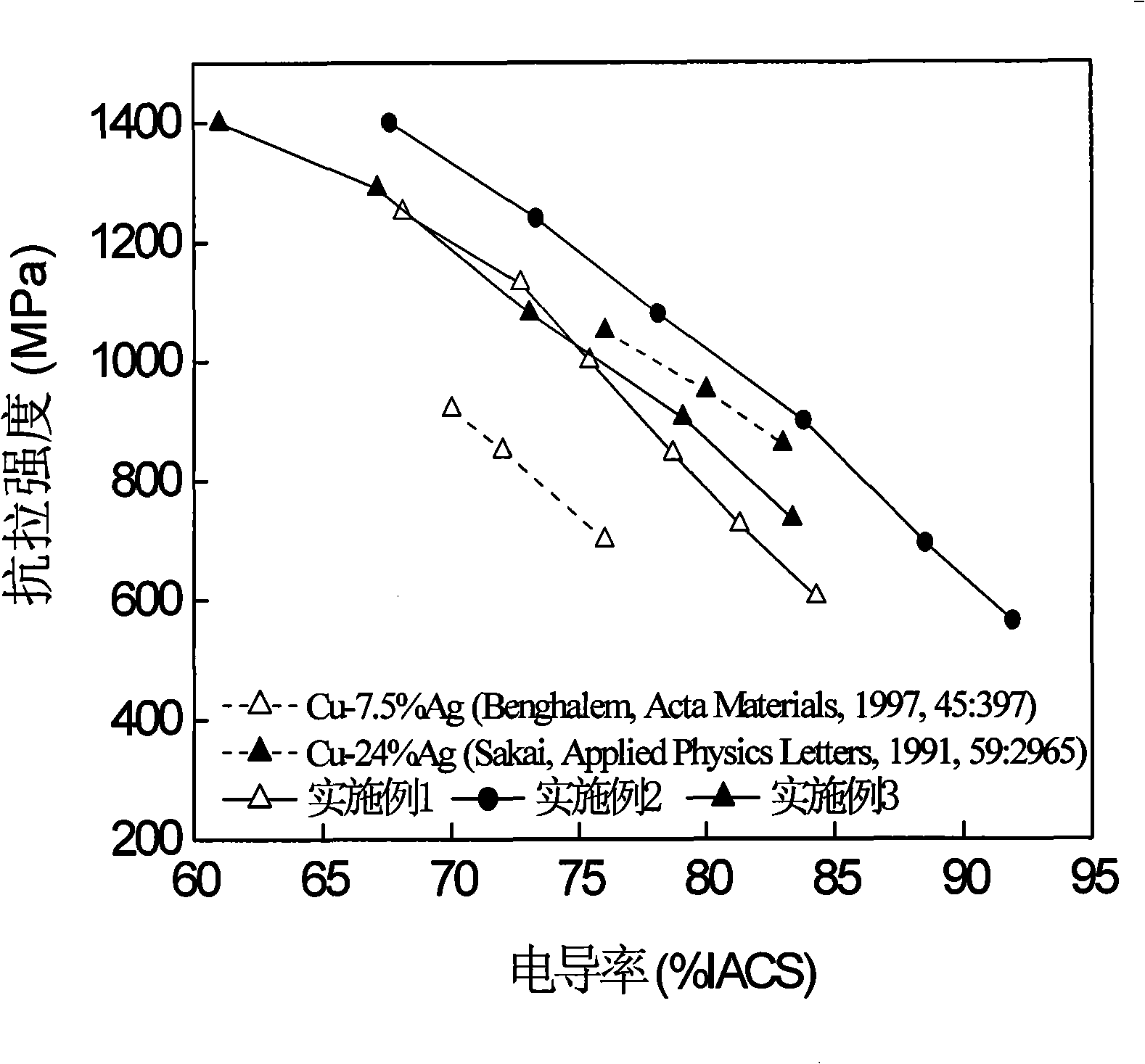

[0042] The tensile strength of the fiber phase composite strengthened Cu-Ag alloy prepared in the above examples can reach 380-1400 MPa under different deformation degrees, and the electrical conductivity can reach (60-92)% IACS (see figure 1 and figure 2 shown), the overall performance reflected from its tensile strength and electrical conductivity matching relat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com