Medical multi-hole implanted alloy material and preparation method thereof

An alloy material and alloy technology are applied in the field of medical porous implanted alloy materials and their preparation, which can solve the problems of high toxicity and high elastic modulus of added elements, and achieve the effects of easy access, low modulus and reduction of metal modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

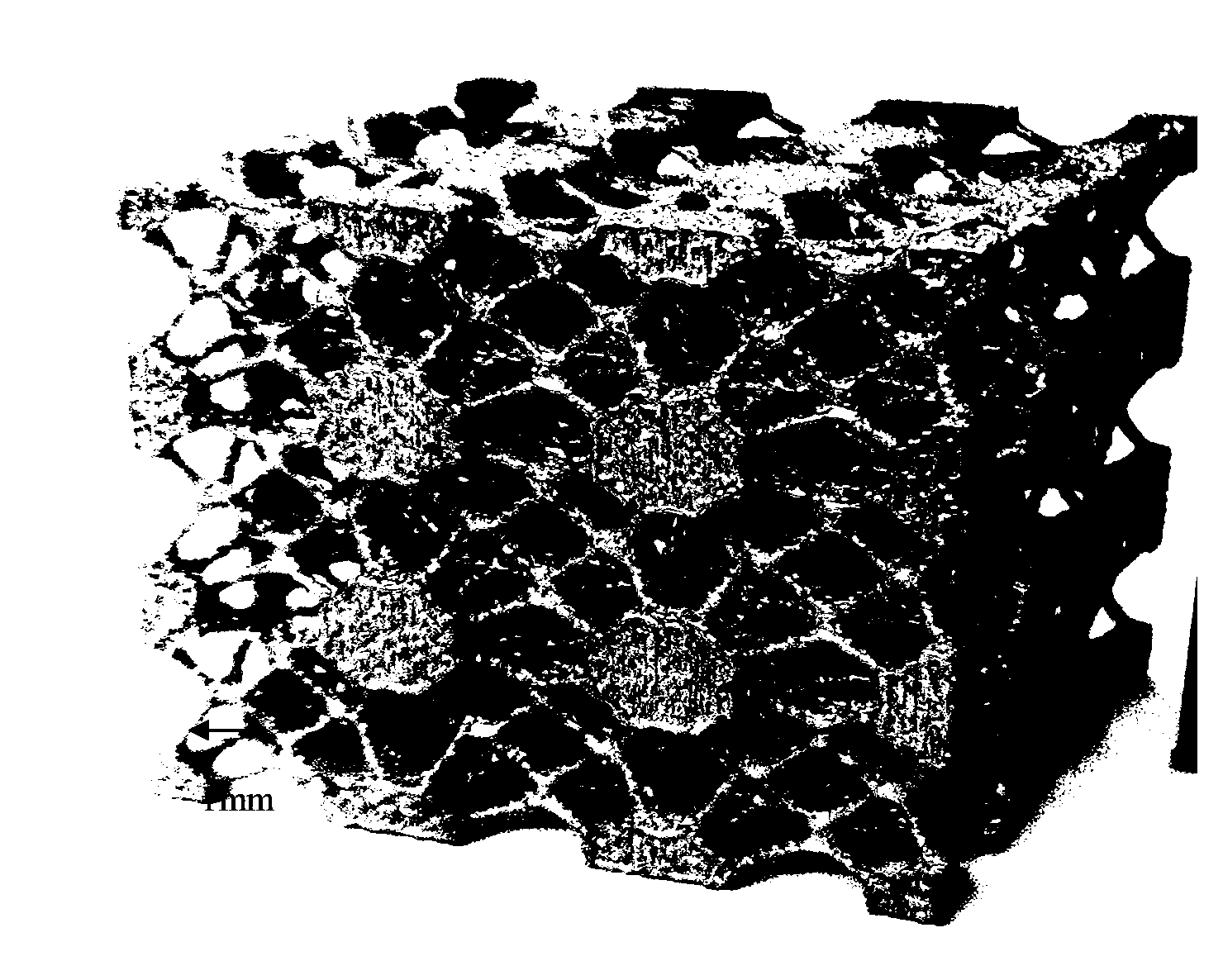

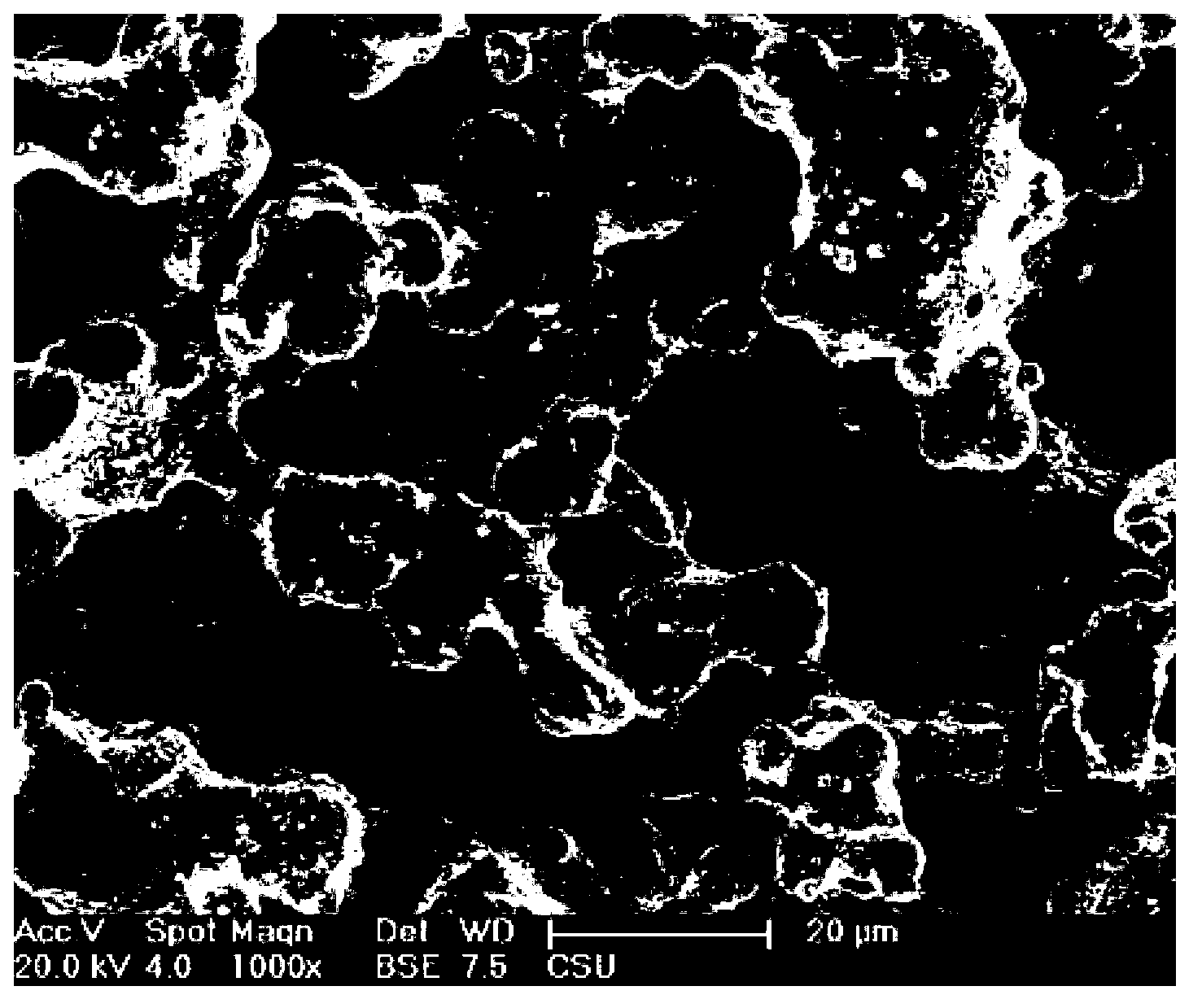

[0030] Example 1 Preparation of a medical porous Ti-28Nb-10Ta-5Zr alloy with a macropore diameter of 1 mm

[0031] In this example, a medical porous Ti-28Nb-10Ta-5Zr alloy with a macropore diameter of 1 mm was prepared by using the electron beam rapid prototyping method. The specific steps are as follows:

[0032] 1) First, use CAD software to build a 20×20×20mm three-dimensional model, the interior is a large hole structure with a diameter of 1mm, and perform surface mesh processing on the three-dimensional model to form an STL format file. According to the process requirements, use the software to discretize the three-dimensional model into a series of The unit of the CAD model is divided into 400 layers along the Z direction, that is, the thickness of each layer is 0.05mm. Import the layered model into the electron beam forming equipment, and input the processing parameters (preheating stage temperature, beam intensity, forming stage temperature, beam intensity, electron be...

Embodiment 2

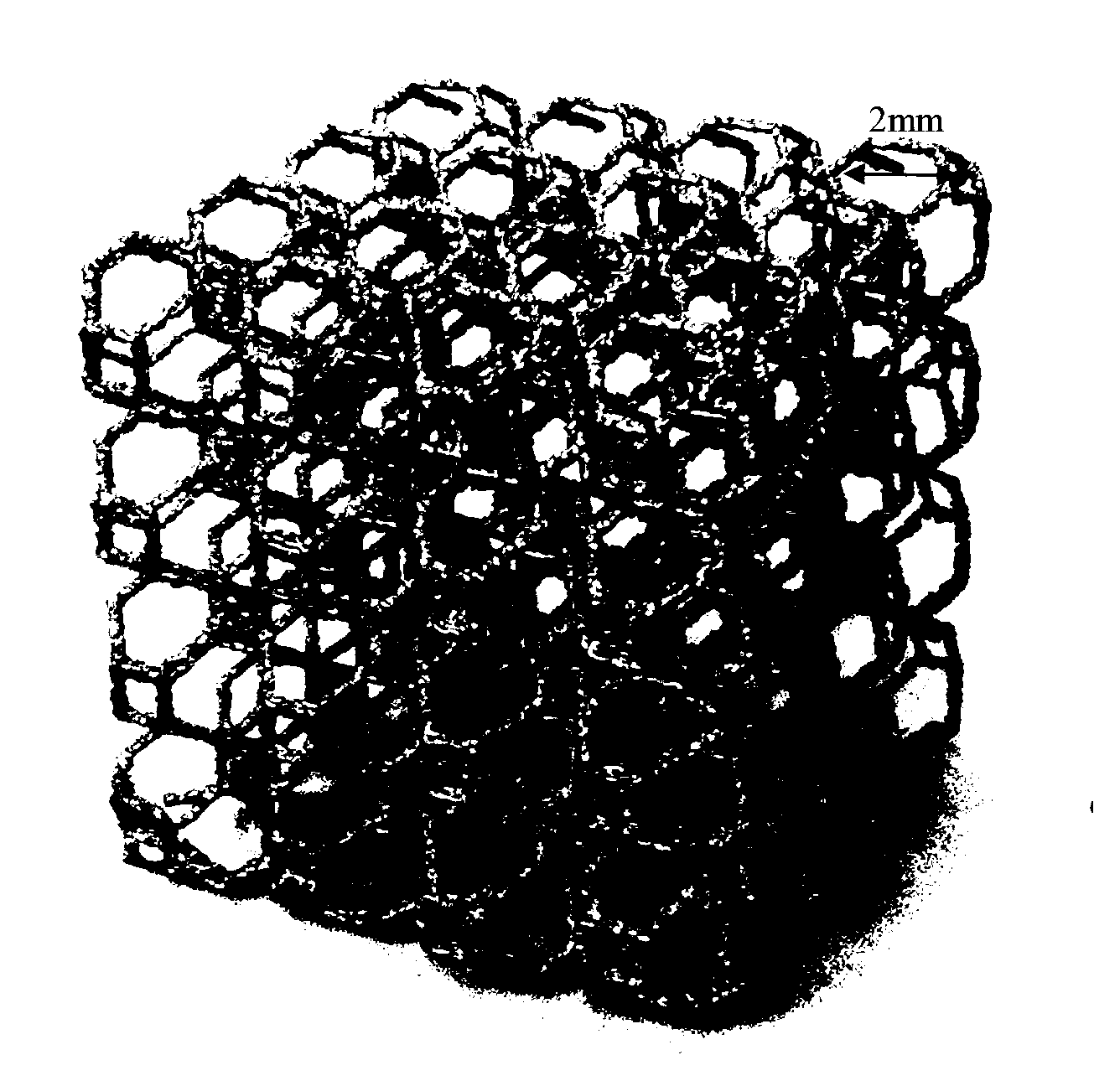

[0035] Example 2 Preparation of a medical porous Ti-32Nb-7Ta-5Zr alloy with a macropore diameter of 2mm

[0036] In this example, a medical porous Ti-32Nb-7Ta-5Zr alloy with a macropore diameter of 2 mm was prepared by the electron beam rapid prototyping method, and the specific steps were as follows:

[0037] 1) First, use CAD software to build a 20×20×20mm three-dimensional model. The interior is a large-pore structure with a diameter of 2mm. The surface grid of the three-dimensional model is processed to form an STL format file. According to the process requirements, the three-dimensional model is discretized into one A series of units divides the CAD model into 400 layers along the Z direction, that is, the thickness of each layer is 0.05mm. Import the layered model into the electron beam forming equipment, and input the processing parameters.

[0038] 2) Screen the gas-atomized spherical Ti-32Nb-7Ta-5Zr alloy powder with a particle size of 80 μm to 100 μm. Level the botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large hole diameter | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com