Train clearance detection device and method

A detection device and detection method technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low tool precision, non-repeatability, and large influence of human factors, so as to achieve uniform light and improve detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

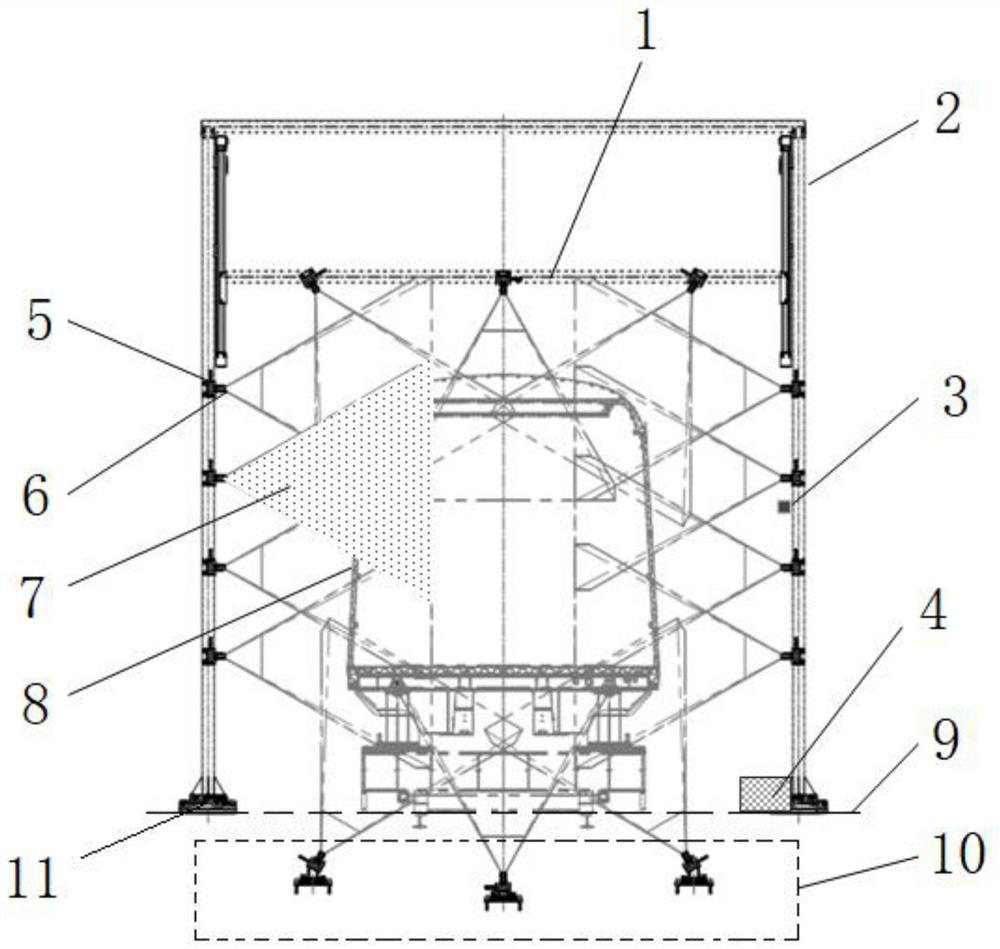

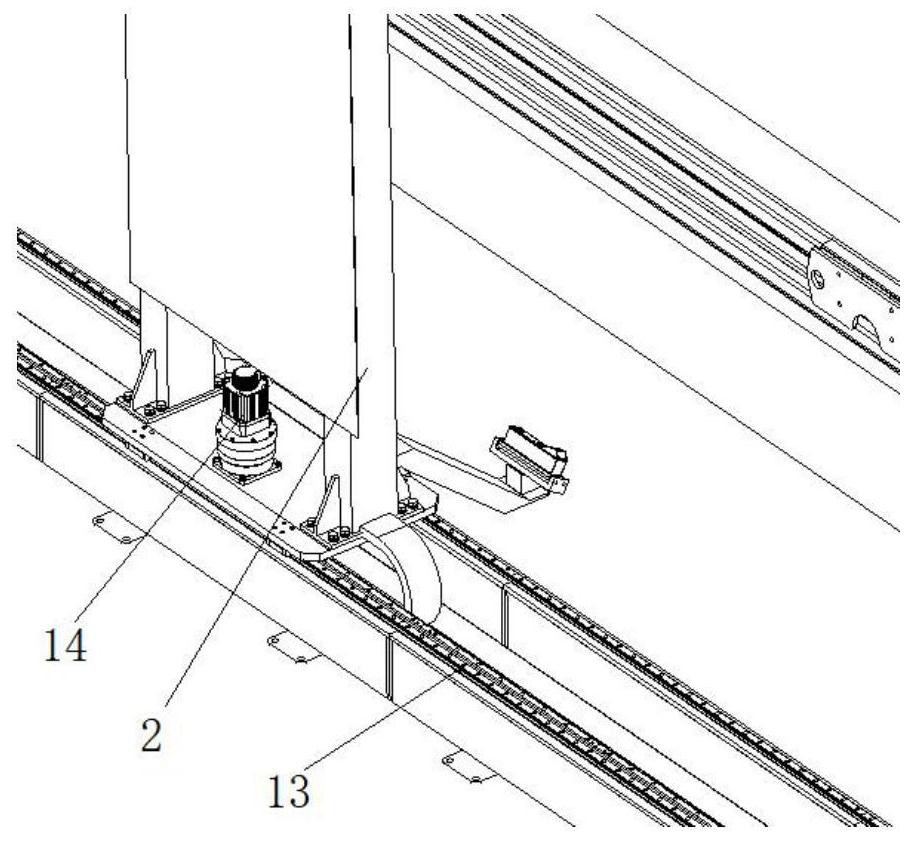

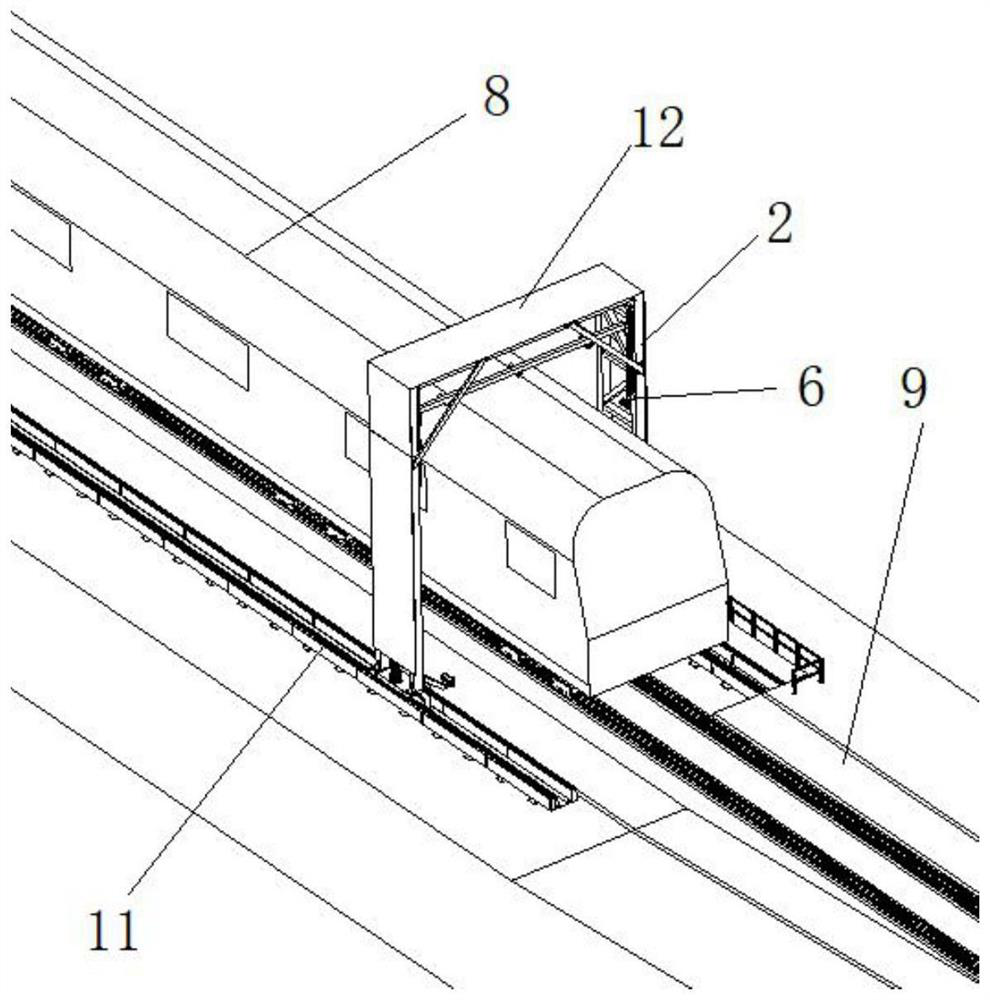

[0040] see Figure 1 ~ Figure 4 , a train limit detection device, comprising a gantry 2, a rangefinder 3, a camera bracket 5, a laser camera 6; the gantry 2 is installed on the foundation 9; the gantry 2 includes two columns and a beam connecting the two columns; The rangefinder 3 is installed on the column for monitoring the position of the body of the train 8; multiple camera brackets 5 are arranged on the beam, the column and in the trench 10, and the camera bracket 5 in the trench 10 is connected to the gantry 2 through a connecting rod Laser camera 6 is installed on each camera support 5; The light plane 7 that laser camera 6 sends is projected on the vehicle body of train 8, realizes 360 degree seamless limit detections to train 8 vehicle body, vehicle bottom. This embodiment includes 14 3D laser cameras 6 , forming a ring in space, and 3 of them are located in the trench 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com