Method for preparing polycarboxylic acid grafted copolymer superplasticizer

A technology of graft copolymer and high-efficiency water-reducing agent, which is applied in the field of concrete admixtures, can solve the problems of limited reduction, lowering of apparent activation energy, and the inability to achieve optimal performance of polycarboxylate water-reducing agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

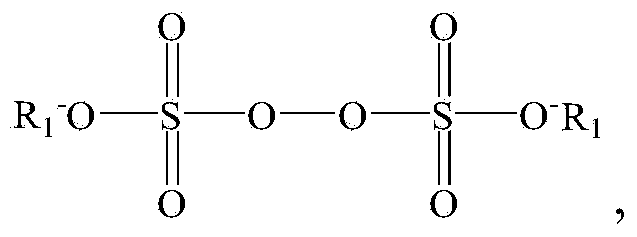

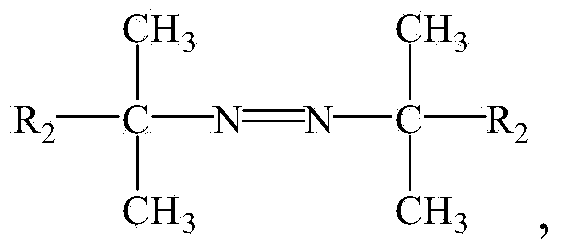

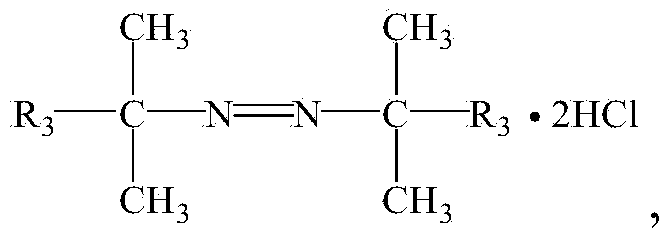

[0112] Specifically, the preparation method includes the following synthesis steps:

[0113] Under low temperature conditions (5-30°C), add initiator I, substance a, substance b, chain transfer agent and reducing agent R aqueous solution into the reaction kettle, stir and react for 1-2h, then neutralize with alkaline solution to pH=6-8, white or light yellow liquid is obtained. Wherein, the alkaline substance used in the alkaline solution is preferably one or more of sodium hydroxide, potassium hydroxide, ethylenediamine and triethanolamine.

[0114] The adding mode of described initiator I, substance a, substance b, chain transfer agent and reducing agent R is as follows:

[0115] Method 1: In the polymerization reaction, the initiator I, substance a, substance b, chain transfer agent and reducing agent R are dissolved in water and then added at one time.

[0116] Method 2: In the polymerization reaction, dissolve substance a, substance b, chain transfer agent, reducing age...

Embodiment 1

[0123] Add 23.75 g of methallyl polyoxyethylene ether (m=12), 0.87 g of ammonium persulfate and 143.8 g of water into a 500 mL four-necked round bottom flask equipped with a thermometer, a stirrer and a spherical condenser. Adjust the temperature of the water bath to 30°C, stir until the methallyl polyoxyethylene ether and ammonium persulfate are dissolved, and use a peristaltic pump to separately mix a solution consisting of 9.12g of acrylic acid and 15.5g of water, 0.081g of sodium bisulfite, 0.001 A solution consisting of 1 g of ferrous sulfate, 0.273 g of 3-mercaptopropionic acid and 15.8 g of water was added dropwise to the four-necked flask within 3 hours. After the dropwise addition, the reaction was stirred for 1.5h. Add 30% sodium hydroxide solution to neutralize to a pH value of 7, and replenish water to obtain a light white liquid with a concentration of 40%. That is to prepare polycarboxylic acid graft copolymer high-efficiency water reducer PC1 at low temperature...

Embodiment 2

[0125] Add 90g of methallyl polyoxyethylene ether (m=51), 159g of methoxypolyethylene glycol acrylate (n =35), 6.8% hydrogen peroxide 12.54g and 138.2g water. Adjust the temperature of the water bath to 5°C, stir until methallyl polyoxyethylene ether and methoxypolyethylene glycol acrylate are dissolved, and use a peristaltic pump to separately mix the solution consisting of 44.91g of acrylic acid and 25g of water and 0.159g of ascorbic acid , 1.17g of sodium thiosulfate, 1.56g of mercaptoacetic acid and 38.2g of water were added dropwise to the four-necked flask within 3 hours. After the dropwise addition, the reaction was stirred for 1.5h. Add 30% potassium hydroxide solution to neutralize until the pH value is 7, and replenish water to obtain a light yellow liquid with a concentration of 40%. That is to prepare the polycarboxylic acid graft copolymer high-efficiency water reducer PC2 at low temperature for the composite initiation system of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com