Cross-linked polycarboxylic acid water reducing agent and preparation method thereof

A polycarboxylic acid, cross-linked technology, applied in the field of concrete admixtures, can solve the problems of limited number of PEG long side chains, unsatisfactory cement particle dispersion effect, etc., and achieves easy reaction control, good workability, and reaction equipment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

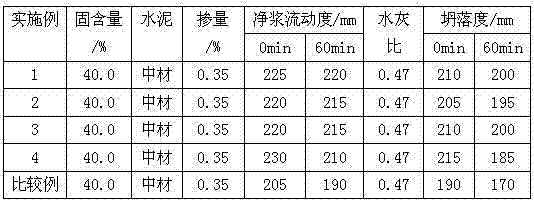

Examples

Embodiment 1

[0027] In the reaction kettle with good airtightness, under continuous stirring, 1500 kg of methallyl alcohol polyoxyethylene ether with a molecular weight of 2400, 150 kg of polyethylene glycol dimethacrylate with a molecular weight of 400, methacrylic sulfonic acid Sodium 20kg, deionized water 775kg, heat up to 45-50°C, stir for 10min, continue to heat up to 60-62°C, add hydrogen peroxide 5.2kg, then slowly add acrylic acid solution (148kg acrylic acid + 56kg water) and solution (2kg thioglycolic acid + 2.4kg sodium ascorbate + 500kg water), drop it within 3 to 3.5 hours, keep it warm for 1 to 1.5 hours, cool down to 50°C after the reaction, replenish 1000 kg of water, add liquid alkali to neutralize to pH = 6.5 to 7, and obtain poly Carboxylic acid mother liquor.

Embodiment 2

[0029] In the reaction kettle with good airtightness, under continuous stirring, 1500 kg of methallyl alcohol polyoxyethylene ether with a molecular weight of 2400, 200 kg of polyethylene glycol dimethacrylate with a molecular weight of 400, sodium methacrylic sulfonate 20kg, 775kg deionized water, heat up to 45-50°C, stir for 10min, continue to heat up to 60-62°C, add 5.2kg of hydrogen peroxide, then slowly add acrylic acid solution (148kg acrylic acid + 56kg water) and solution (2kg thioglycolic acid + 2.4kg sodium ascorbate + 500kg water), drop it within 3-3.5 hours, keep warm for 1-1.5 hours, cool down to 50°C after the reaction, replenish 1100 kg of water, add liquid alkali to neutralize to pH=6.5-7, and obtain polycarboxylate acid mother liquor.

Embodiment 3

[0031] In the reaction kettle with good airtightness, under continuous stirring, 1500 kg of methallyl alcohol polyoxyethylene ether with a molecular weight of 2400, 150 kg of polyethylene glycol dimethacrylate with a molecular weight of 400, methacrylic sulfonic acid Sodium 20kg, deionized water 775kg, heat up to 45-50°C, stir for 10min, continue to heat up to 60-62°C, add hydrogen peroxide 5.2kg, then slowly add acrylic acid solution (160kg acrylic acid + 56kg water) and solution (2kg thioglycolic acid + 2.4kg sodium ascorbate + 500kg water), drop it within 3-3.5 hours, keep it warm for 1-1.5 hours, cool down to 50°C after the reaction, add water 1050kg, add liquid alkali to neutralize to pH=6.5-7, and obtain polycarboxylate acid mother liquor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com