Unfired magnesia-calcium-carbon brick for preventing steel from being clamped in permanent layer of steel ladle and preparation method thereof

A technology of magnesia-calcium-carbon bricks and permanent layers, which is applied in the field of refractory materials, can solve the problems of waste of resources, early removal of refractory materials, and steel sandwiching in permanent layers, and achieve the effect of avoiding steel sandwiching in permanent layers and improving thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

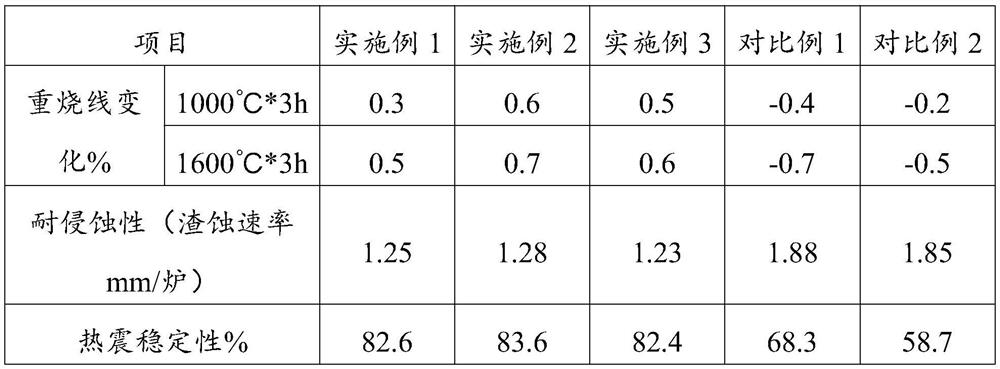

Examples

Embodiment 1

[0030] (1) Preparation of co-grinding powder: The raw material composition is: fused magnesia with a particle size of less than 0.05 mm, 320 mesh metal magnesium powder, lanthanum oxide powder with a particle size of 5 μm, titanium oxide powder with a particle size of 10 nm, and α- Alumina micropowder, 150-mesh pitch, urotropine, carbon nanotubes with a length of 25 μm and a diameter of 0.2 nm. Put into the vibrating mill for co-grinding for 10min;

[0031] (2) Take 16 parts of magnesia-calcium sand with a particle size of 3-5mm, 22 parts of magnesia-calcium sand with a particle size of 1-3mm and 3 parts of magnesia-calcium sand with a particle size of 0.05-1mm; 6 parts of fused magnesia with a particle size of 3-5mm , 3 parts of 1-3mm fused magnesia and 27 parts of 0.05-1mm fused magnesia; 0.1 part of zirconia with a particle size of 0.2mm; dry mix for 2 minutes, and then slowly add 2 parts at one time within 2 minutes with a viscosity of 8000Pa For the anhydrous phenolic re...

Embodiment 2

[0035](1) Preparation of co-grinding powder: The raw materials are composed of fused magnesia with a particle size of less than 0.05mm, 325 mesh metal magnesium powder, lanthanum oxide powder with a particle size of 55μm, titanium oxide powder with a particle size of 60nm, and α -Alumina micropowder, 170 mesh pitch, urotropine, carbon nanotubes with a length of 65 μm and a diameter of 1.4nm, and the addition ratio of each raw material is: 5:0.9:1.0:0.8:0.7:1.0:1.1:0.5. The above-mentioned raw materials were put into a vibration mill for co-grinding for 13 minutes;

[0036] (2) Take 18 parts of magnesia-calcium sand with a particle size of 3-5mm, 25 parts of magnesia-calcium sand with a particle size of 1-3mm and 5 parts of magnesia-calcium sand with a particle size of 0.05-1mm; 8 parts of fused magnesia with a particle size of 3-5mm , 5 parts of 1-3mm fused magnesia and 30 parts of 0.05-1mm fused magnesia; 1.3 parts of zirconia with a particle size of 2mm; dry mix for 2.5 minu...

Embodiment 3

[0040] (1) Co-grinding powder preparation: The raw materials are composed of fused magnesia with a particle size of less than 0.05 mm, 330 mesh metal magnesium powder, lanthanum oxide powder with a particle size of 100 μm, titanium oxide powder with a particle size of 100 nm, and α- Alumina micropowder, 200-mesh pitch, urotropine, carbon nanotubes with a length of 100 μm and a diameter of 2.5 nm, the ratio of each raw material is: 8:1.5:1.5:1.5:1.5:2:2:1, put Put into vibrating mill and grind together for 15min;

[0041] (2) Take 20 parts of magnesia-calcium sand with a particle size of 3-5mm, 28 parts of magnesia-calcium sand with a particle size of 1-3mm and 7 parts of magnesia-calcium sand with a particle size of 0.05-1mm; 10 parts of fused magnesia with a particle size of 3-5mm , 7 parts of 1-3mm fused magnesia and 33 parts of 0.05-1mm fused magnesia; 2.5 parts of zirconia with a particle size of 3mm; dry mix for 3 minutes, and then slowly add 4 parts within 2 minutes at o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com