A kind of ceramic repair material and ceramic repair method

A technology for repairing materials and ceramics, which is applied in the field of ceramic repairing materials and ceramic repairing. It can solve the problems of lower firing temperature, glaze flow at trademarks, and insufficient yield rate, etc., and achieve the effects of reducing shrinkage, good repairing effect, and avoiding cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

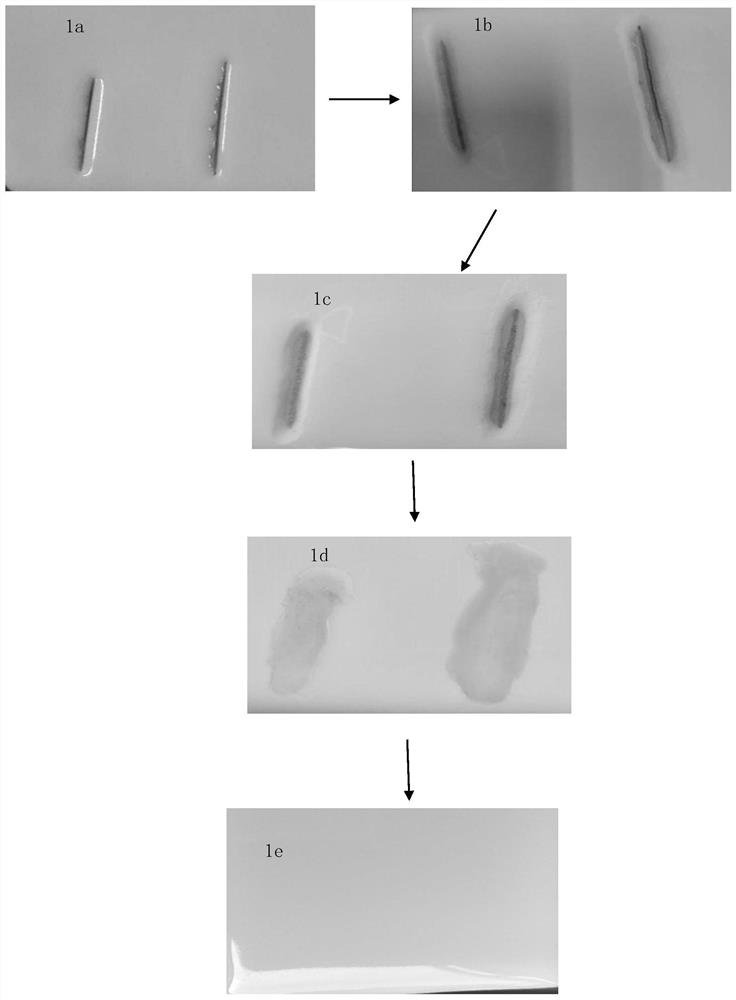

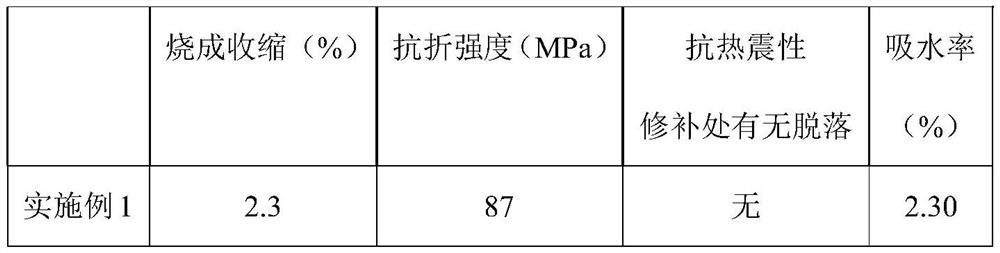

[0027] The ceramic repair materials of Examples 1 to 4 are batched according to the composition in parts by weight in Table 1, dried after batching, and ball milled by a fast ball mill for 3 to 5 minutes to mix the materials uniformly, and pass through an 80-mesh sieve after grinding; according to materials: water: glycerin The mass ratio is 100:18:5, and the ceramic repair material is refined into lumps as the repair primer. The dry powder composition of the bottom glaze is: 13 parts of quartz, 32 parts of potassium feldspar, 1 part of dolomite, 5 parts of zinc oxide, 1 part of alumina, 9 parts of zirconium silicate, 5 parts of kaolin, 25 parts of wollastonite, 10 parts of stone, 2 parts of frit, 0.2 part of alkali surface, 0.2 part of CMC dry powder. Among them, the praseodymium yellow material is a kind of color material, and the specific color material can be mixed and selectively added according to the proportion of different green body colors.

[0028] The raw material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com