A kind of low-temperature high-strength toughness cement slurry and its preparation method and application

A high-strength and toughness, cement slurry technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low elastic modulus, slow strength development, low strength, etc., achieve low elastic modulus, improve packing density, etc. the effect of improving the early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

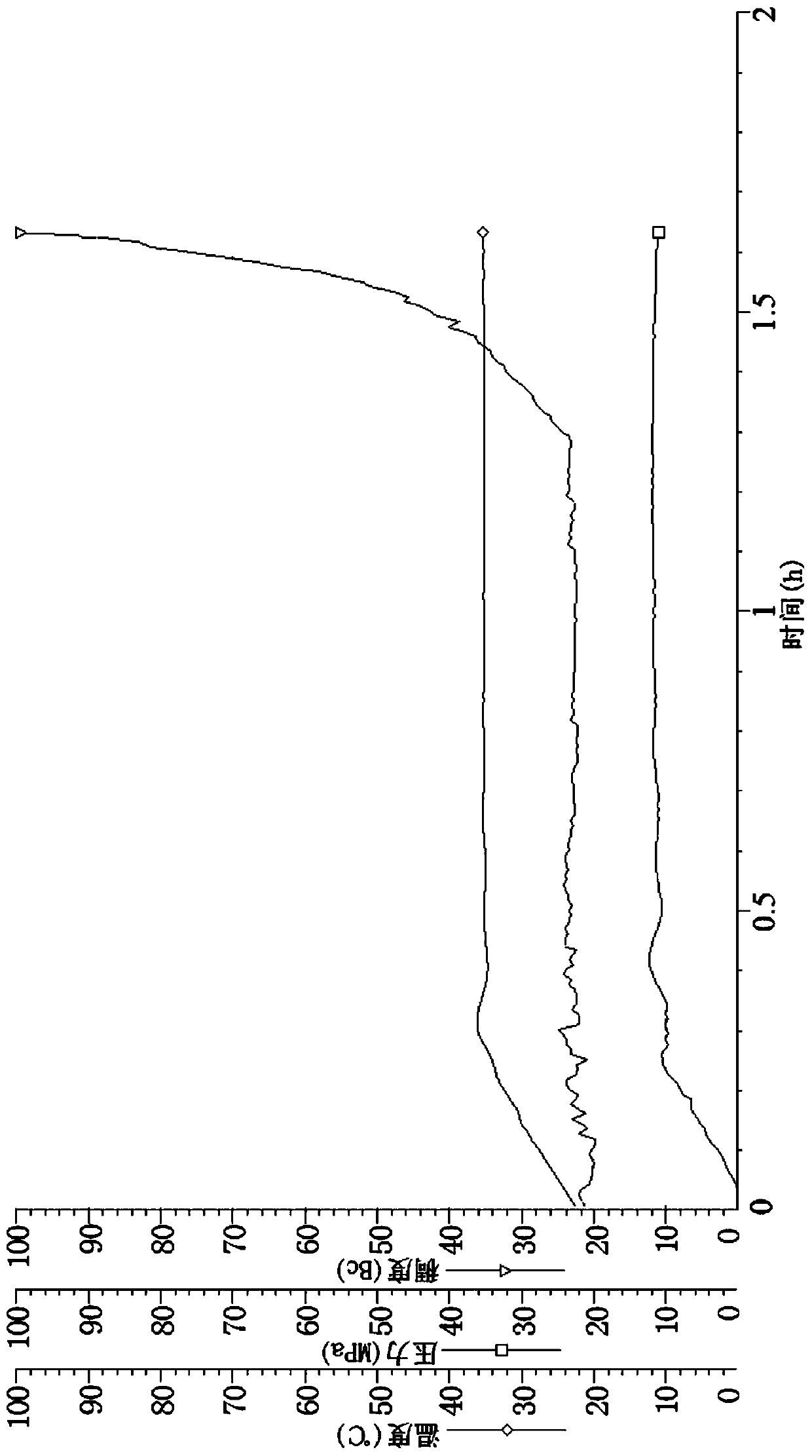

Embodiment 1

[0037] This embodiment provides a low-temperature high-strength toughness cement slurry, in parts by weight, its raw material components include:

[0038]

[0039] The present embodiment also provides the preparation method of the above-mentioned low-temperature high-strength toughness cement slurry, which includes the following steps:

[0040] Weigh the materials according to the above ratio, mix the early strength agent, low-temperature high-activity material, expansion toughness material, sulfonated acetone-formaldehyde condensate, polyvinyl alcohol and G-grade oil well cement to obtain a dry mixture;

[0041] Mix tributyl phosphate and clear water evenly to obtain a wet mix;

[0042]At the speed of 4000±200r / min, stir the dry mixture evenly into the wet mixture within 15s. After the dry mixture is completely wetted, continue stirring at the speed of 12000±500r / min for 35s to obtain low temperature and high strength. Tough cement slurry with a density of 1.88g / cm 3 . ...

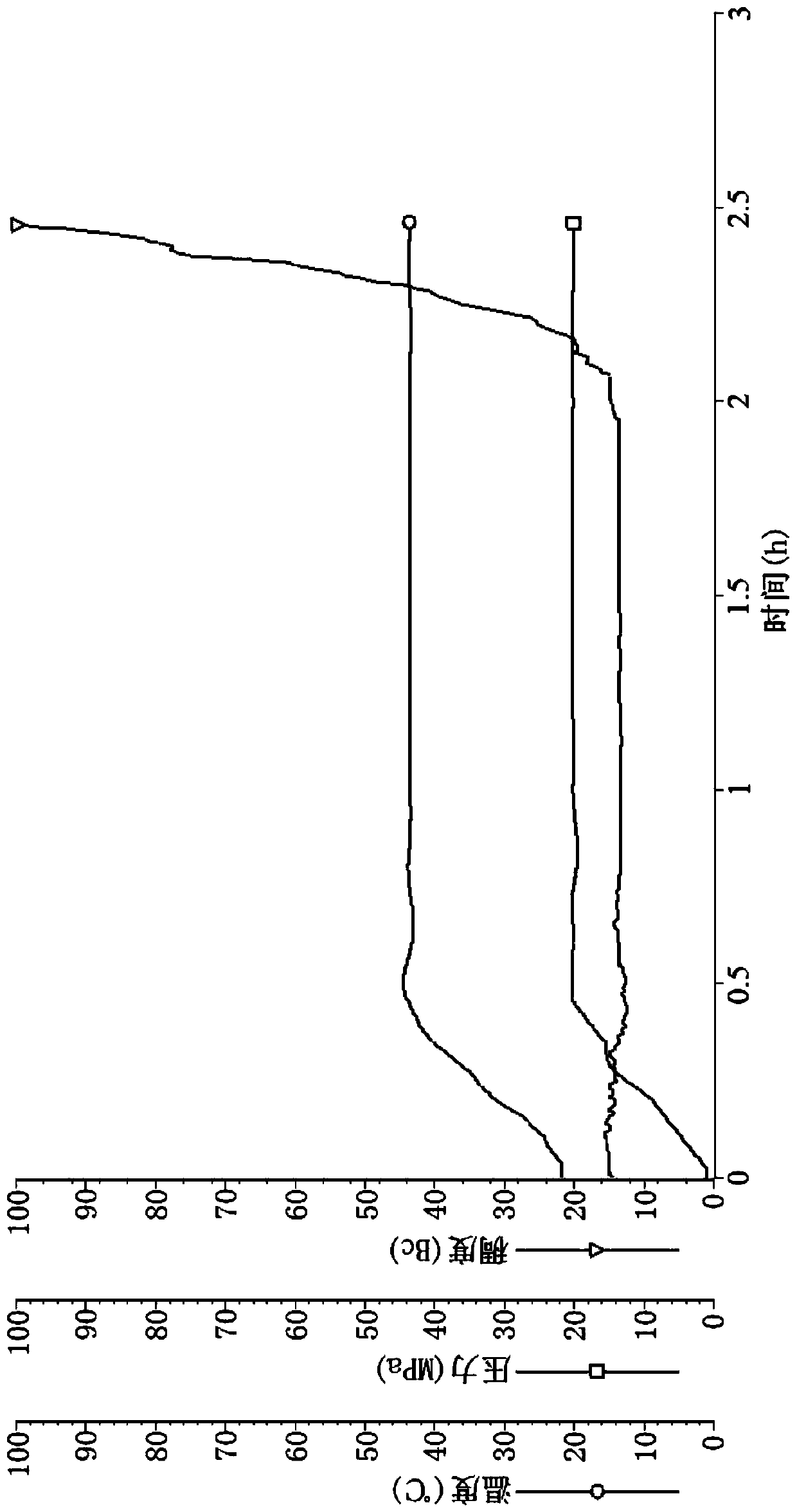

Embodiment 2

[0044] This embodiment provides a low-temperature high-strength toughness cement slurry, in parts by weight, its raw material components include:

[0045]

[0046] The present embodiment also provides the preparation method of the above-mentioned low-temperature high-strength toughness cement slurry, which includes the following steps:

[0047] Weigh the materials according to the above ratio, mix the early strength agent, low-temperature high-activity material, expansion toughness material, sulfonated acetone-formaldehyde condensate, polyvinyl alcohol, modified starch and G-grade oil well cement to obtain a dry mixture;

[0048] Mix tributyl phosphate and clear water evenly to obtain a wet mix;

[0049] At the speed of 4000±200r / min, stir the dry mixture evenly into the wet mixture within 15s. After the dry mixture is completely wetted, continue stirring at the speed of 12000±500r / min for 35s to obtain low temperature and high strength. Tough cement slurry with a density ...

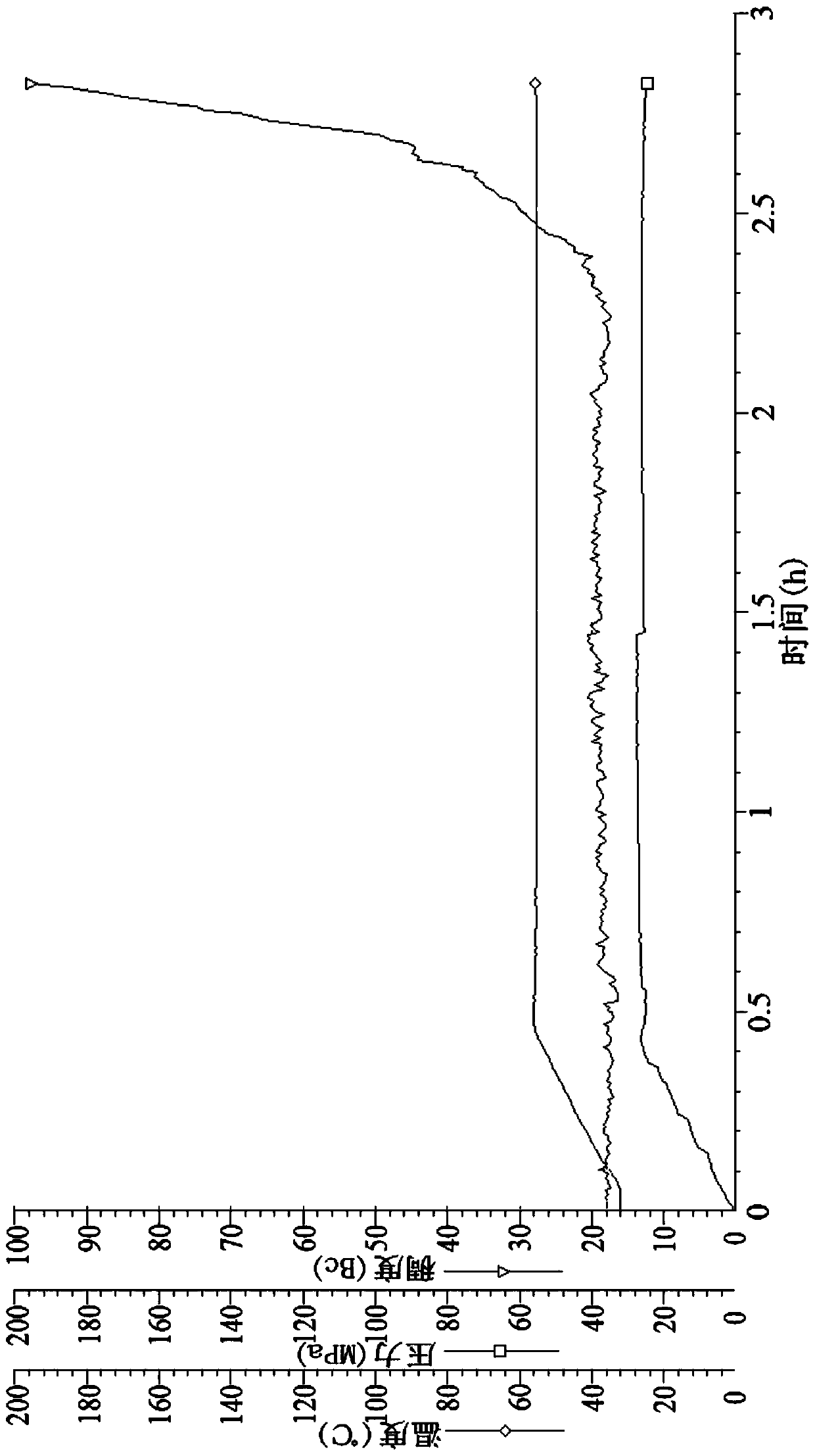

Embodiment 3

[0051] This embodiment provides a low-temperature high-strength toughness cement slurry, in parts by weight, its raw material components include:

[0052]

[0053] The present embodiment also provides the preparation method of the above-mentioned low-temperature high-strength toughness cement slurry, which includes the following steps:

[0054] Weigh the materials according to the above ratio, and mix the early strength agent, low-temperature high-activity material, expansion toughness material, sulfonated acetone-formaldehyde condensate and G-grade oil well cement to obtain a dry mixture;

[0055] Mix 2-acrylamido-2-methylpropanesulfonic acid, hydroxyethylidene diphosphonic acid, tributyl phosphate and clear water evenly to obtain a wet mixture;

[0056] At the speed of 4000±200r / min, stir the dry mixture evenly into the wet mixture within 15s. After the dry mixture is completely wetted, continue stirring at the speed of 12000±500r / min for 35s to obtain low temperature and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com