Concrete anti-seepage and anti-freezing admixture for plateau complex environment and preparation method thereof

A complex environment and admixture technology, applied in the field of building materials, can solve the problems of low/negative temperature construction and poor durability, and achieve the effect of improving mechanical properties and durability and prolonging the effective construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

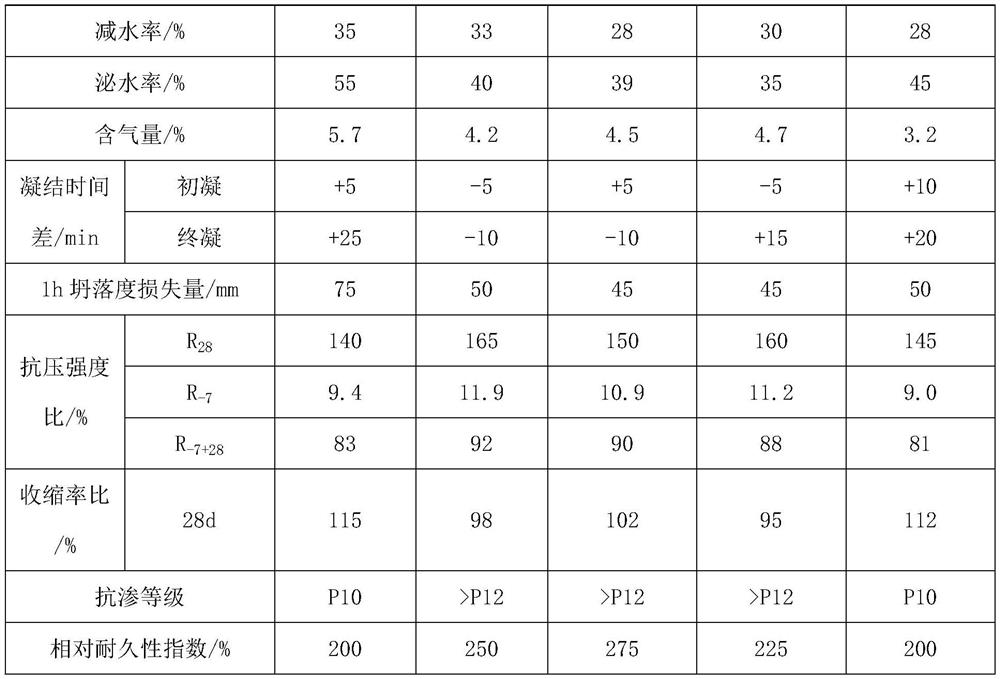

Examples

preparation example Construction

[0022] A method for preparing a concrete anti-seepage and antifreeze admixture adapted to the complex environment of plateaus, comprising the following steps:

[0023] 1) Weigh each raw material respectively according to the mass ratio of the above-mentioned raw materials;

[0024] 2) Mix and disperse calcium nitrite and calcium formate evenly, and record it as A;

[0025] 3) Methanol and ethylene glycol are mixed and dispersed evenly, and recorded as B;

[0026] 4) Add deionized water and polyoxyethylene ether into the beaker, and stir evenly with a magnetic stirrer at a speed of 30-50 r / min at 30-50 ° C, denoted as C;

[0027] 5) Slowly add sodium dodecylbenzenesulfonate, sodium gluconate, A and B into C in sequence, mix and stir evenly, and record it as D;

[0028] 6) Finally, add sodium polyacrylate to D, and use a magnetic stirrer to stir and mix evenly at a speed of 20-40 r / min to obtain a viscous anti-seepage and antifreeze additive.

Embodiment 1

[0030] The anti-seepage and anti-freeze admixture for concrete adapted to the complex environment of the plateau given in this example is composed of the following raw materials in terms of weight percentage:

[0031] Sodium dodecylbenzenesulfonate 12%, calcium nitrite 8%, calcium formate 4.5%, methanol 5.7%, ethylene glycol 5.4%, sodium gluconate 3.2%, sodium polyacrylate 2.3%, polyoxyethylene ether 12.5% , 46.4% deionized water. The sum of the weight percentages of raw materials is 100%.

[0032] The preparation method of the above-mentioned concrete anti-seepage and anti-freeze admixture adapted to the complex environment of the plateau is carried out according to the following steps:

[0033] Step 1, weighing each raw material respectively according to the mass ratio of the above-mentioned raw materials;

[0034] Step 2, mix and disperse calcium nitrite and calcium formate evenly, record it as A, and set aside;

[0035] Step 3, mix and disperse methanol and ethylene gly...

Embodiment 2

[0040] The difference between this embodiment and the above-mentioned embodiment 1 lies in the ratio of each raw material. The concrete anti-seepage and antifreeze admixture adapted to the complex environment of the plateau is composed of the following raw materials in weight percentage: 10% sodium dodecylbenzenesulfonate, 10% calcium nitrite, and 6% calcium formate , Methanol 5%, Ethylene Glycol 4%, Sodium Gluconate 2%, Sodium Polyacrylate 3%, Polyoxyethylene Ether 14%, Ionized Water 46%. The sum of the weight percentages of raw materials is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com