Early-strength polycarboxylic acid composite water reducer and preparation method thereof

A composite superplasticizer and polycarboxylic acid technology, applied in the field of concrete admixtures, can solve the problems of polycarboxylate superplasticizers such as low molecular weight, obvious chain transfer effect, and insufficient slump performance, and achieve long-term storage uniformity and stability, early Excellent performance and good slump protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

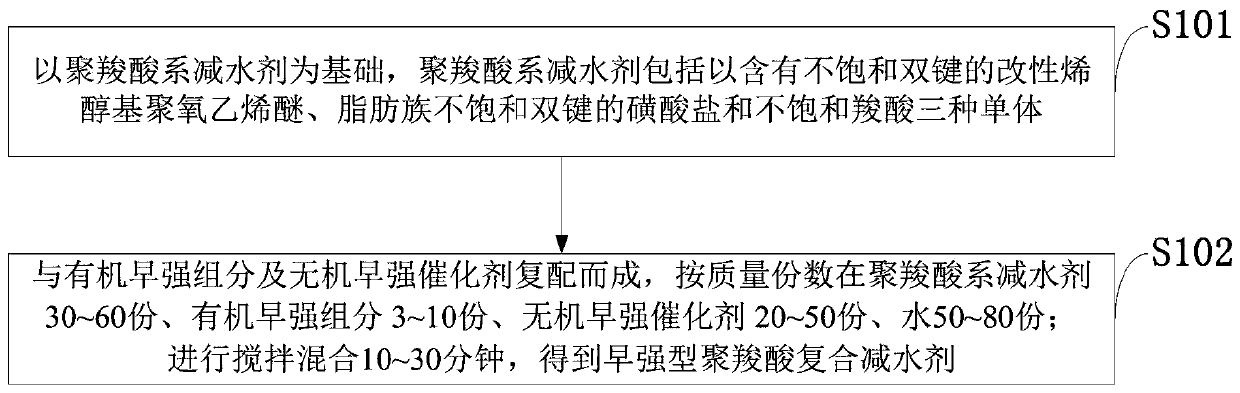

[0034] Such as figure 1 As shown, the preparation method of the early-strength polycarboxylate composite water reducer provided by the embodiment of the present invention includes the following steps:

[0035] S101: Based on polycarboxylate water reducers, polycarboxylate water reducers include modified enol polyoxyethylene ethers containing unsaturated double bonds, sulfonates of aliphatic unsaturated double bonds and unsaturated Three monomers of saturated carboxylic acid;

[0036] S102: Compounded with organic early-strength components and inorganic early-strength catalysts, in parts by mass, 30-60 parts of polycarboxylic acid-based water reducer, 3-10 parts of organic early-strength components, and 20 parts of inorganic early-strength catalysts ~ 50 parts, water 50-80 parts; stirring and mixing for 10-30 minutes to obtain an early-strength polycarboxylic acid composite water reducer.

Embodiment 1

[0039] The first step: prepare material A: dissolve 2.64 parts of sodium methacrylate with deionized water, stir and dissolve, add 9.60 parts of acrylic acid, stir well and set aside;

[0040] Step 2: Prepare material B: dissolve 0.54 parts of mercaptopropionic acid with deionized water;

[0041] Step 3: Dissolve 95 parts of isopentenol polyoxyethylene ether with a molecular weight of 3800 in deionized water, then add 1.07 parts of ammonium persulfate, raise the temperature to 60±2°C, and add A and B materials dropwise at a uniform speed. The dropping time is 1.5h, and the dropping time of material B is 2h;

[0042] Step 4: Keep the temperature constant for 2.5 hours to obtain a polycarboxylate water reducer.

[0043]Step 5: Take 42 parts of the polycarboxylate water-reducer (40% concentration) prepared above, and then add 60 parts of water, 4 parts of triethanolamine, 21 parts of magnesium thiocyanate, and 10 parts of formic acid in a stirring state. Calcium, fully dissolve...

Embodiment 2

[0045] Step 1: Prepare material A: Dissolve 2.15 parts of sodium methacrylate in deionized water, stir to dissolve, add 9.82 parts of acrylic acid, stir well and set aside;

[0046] Step 2: Prepare material B: dissolve 0.54 parts of mercaptopropionic acid with deionized water;

[0047] Step 3: Dissolve 95 parts of isopentenol polyoxyethylene ether with a molecular weight of 3800 in deionized water, then add 1.07 parts of ammonium persulfate, raise the temperature to 60±2°C, add material A, B, and material A at a uniform speed The dropping time is 1.5h, and the dropping time of material B is 2h;

[0048] The fourth step: keep the temperature for 2.5 hours to obtain a polycarboxylate water reducer.

[0049] Step 5: Take 40 parts of the polycarboxylate water-reducer (concentration: 40%) prepared above, and then add 63 parts of water, 3.5 parts of triethanolamine, 18 parts of magnesium thiocyanate, and 11 parts of formic acid in a stirring state. Calcium, fully dissolved and lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com