Formable polylactic resin composition and preparation method for plastic strip thereof

A technology of polylactic acid resin and composition, which is applied in the preparation of polylactic acid resin composition and its plastic strips, and the field of modified lactic acid composition, which can solve the problems of complex production process, high production cost, easy to scratch masks, etc., and achieve The effect of good surface gloss, low cost and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

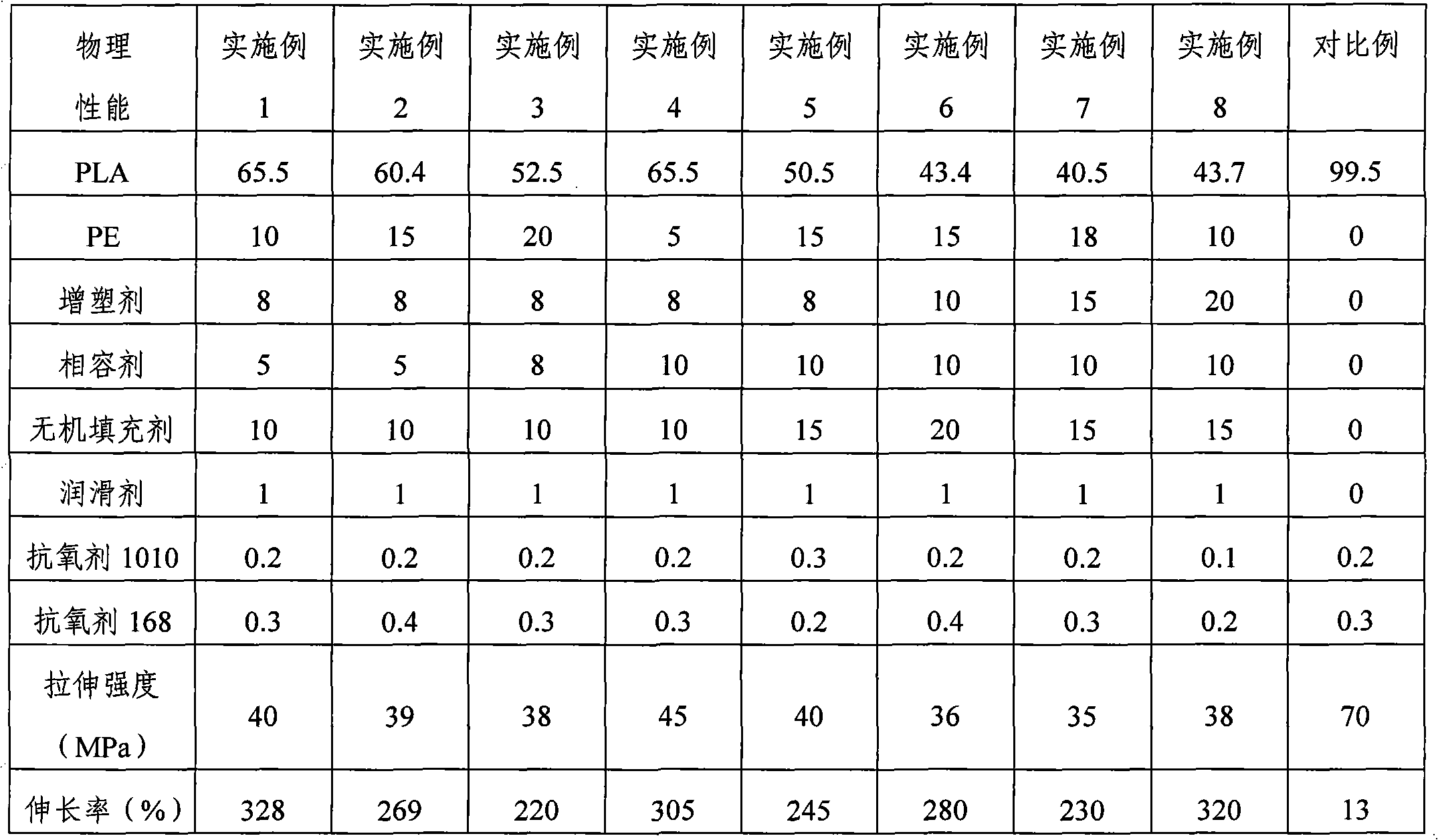

Examples

Embodiment 1

[0061] 1) Take the following substances in weight percentage: 65.5% PLA resin (4032D, number average molecular weight is 120,000-150,000), 10% HDPE resin (2200J, MFR is 5.5g / 10min), 8% PEG-1000, 5% EVA , 10% CaCO 3 (2500 order), 1% calcium stearate, 0.2% antioxidant 1010 and 0.3% antioxidant 168, add in mixer premixing, stir successively, mixing temperature is 30 ℃, and mixer rotating speed is 500 rev / mins, The mixing time is 5 minutes;

[0062] 2) Put the above-mentioned mixed materials into the injection molding machine, and extrude them into plastic strips with mechanical properties; the thickness of the plastic strips is 1.2mm, and the width is 35mm. The temperature is 165~175℃, 180~190℃, 175~185℃, 175~185℃ respectively;

[0063] 3) Put the plastic strip extruded by the injection molding machine into the cooling water tank, and cool the temperature of the plastic strip to 60-70°C;

[0064] 4) Stretch and roll the above-mentioned cooled plastic strip through a rolling ma...

Embodiment 2

[0067] 1) Take the following substances in weight percentage: 60.4% PLA resin (4042D, number average molecular weight is 120,000-150,000), 15% HDPE resin (2000J, MFR is 4g / 10min), 8% PEG-800, 5% EVA, 10% talcum powder (2500 mesh), 1% calcium stearate, 0.2% antioxidant 1010 and 0.4% antioxidant 168, add to the mixer in turn for premixing and stirring, the mixing temperature is 30°C, and the mixer speed is 300 rev / min, the mixing time is 6 minutes;

[0068] 2) Put the above-mentioned mixed materials into the injection molding machine, and extrude them into plastic strips with mechanical properties; the thickness of the plastic strips is 1.4mm, and the width is 30mm. The temperature is 165~175℃, 180~190℃, 175~185℃, 175~185℃ respectively;

[0069] 3) Put the plastic strip extruded by the injection molding machine into the cooling water tank, and cool the temperature of the plastic strip to 65-75°C;

[0070] 4) Stretch and roll the above-mentioned cooled plastic strip through a r...

Embodiment 3

[0073] 1) Take the following materials in weight percentage: 52.5% PLA resin (4060D, number average molecular weight is 150,000-180,000), 20% HDPE resin (2400J, MFR is 8g / 10min), 8% PEG-400, 8% EVA, 10%CaCO 3 (2000 order), 1% calcium stearate, 0.2% antioxidant 1010 and 0.3% antioxidant 168, add mixer premixing, stirring successively, mixing temperature is 40 ℃, and mixer rotating speed is 450 rev / mins, The mixing time is 3 minutes;

[0074] 2) Put the above-mentioned mixed materials into the injection molding machine, and extrude them into plastic strips with mechanical properties; the thickness of the plastic strips is 1.3mm, and the width is 32mm. The temperature is 165~175℃, 180~190℃, 175~185℃, 175~185℃ respectively;

[0075] 3) Put the plastic strip extruded by the injection molding machine into the cooling water tank, and cool the temperature of the plastic strip to 70-80°C;

[0076] 4) Stretch and roll the above-mentioned cooled plastic strip through a rolling machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com