Water-based woodware anti-formaldehyde varnish and preparing method thereof

An anti-formaldehyde and water-based technology, applied in the field of materials, can solve the problems of disappearing and reducing the ability to remove formaldehyde, and achieve the effect of improving flexibility, fast drying speed and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

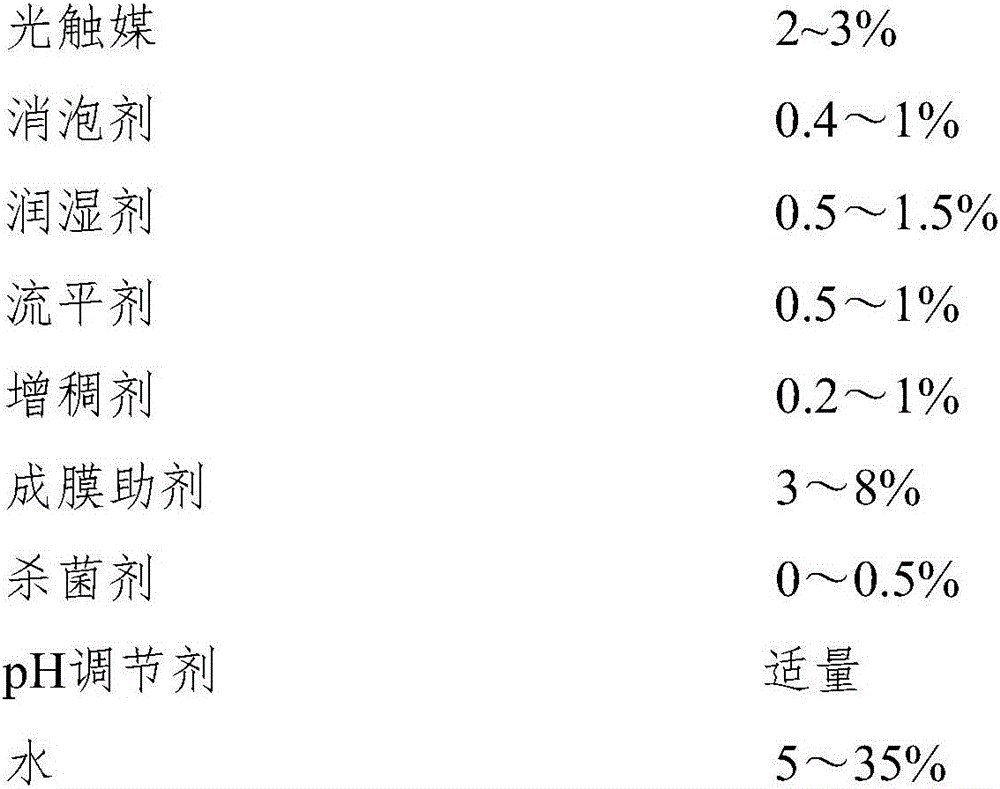

[0044] A water-based formaldehyde-resistant varnish for wood, consisting of the following components:

[0045]

[0046]

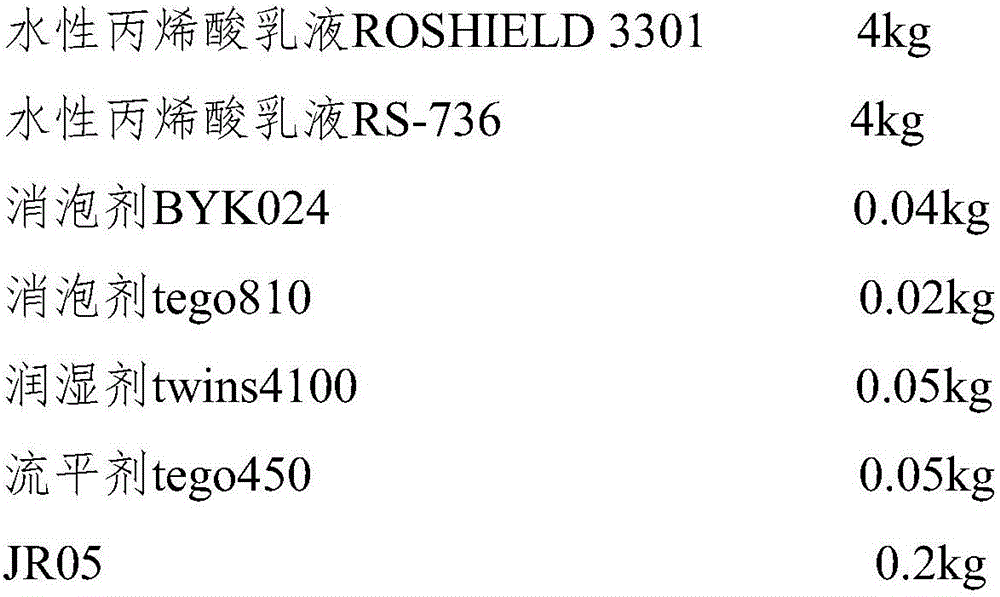

[0047]This embodiment also provides the preparation method of the above-mentioned water-based formaldehyde-resistant woodware varnish, which is specifically: first pour 4kg of water-based acrylic emulsion ROSHIELD 3301 and 4kg of water-based acrylic emulsion RS-736 into the dispersion container, and adjust the pH of 0.02kg under low-speed stirring. Add agent AMP95 into the dispersion container, adjust the pH value to 8-9, then add 0.01kg fungicide MV, 0.3kg dipropylene glycol butyl ether DPNB, 0.3kg ethylene glycol monobutyl ether BCS, 0.04kg defoamer BYK024, 0.02kg Defoamer tego810, 0.05kg wetting agent twins4100, and 0.05kg leveling agent tego450 are pre-mixed evenly, and slowly added to the dispersion container under stirring, and 0.2kg of JR05 is slowly added under the condition of ventilation and dust removal and stirred evenly , add 0.03kg thick...

Embodiment 2

[0049] A water-based formaldehyde-resistant varnish for wood, consisting of the following components:

[0050]

[0051]

[0052] This embodiment provides the preparation method of above-mentioned water-based formaldehyde-resistant woodware varnish simultaneously, and its preparation method is the same as embodiment 1.

Embodiment 3

[0054] A water-based formaldehyde-resistant varnish for wood, consisting of the following components:

[0055]

[0056] This embodiment provides the preparation method of above-mentioned water-based formaldehyde-resistant woodware varnish simultaneously, and its preparation method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com