Novel melamine water reducer and preparation method

A technology of melamine and water reducing agent, applied in the field of concrete admixtures, can solve the problems of difficult to guarantee the quality of the project, the effect of water reduction and water retention is not obvious, and the impact of engineering construction, etc. adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

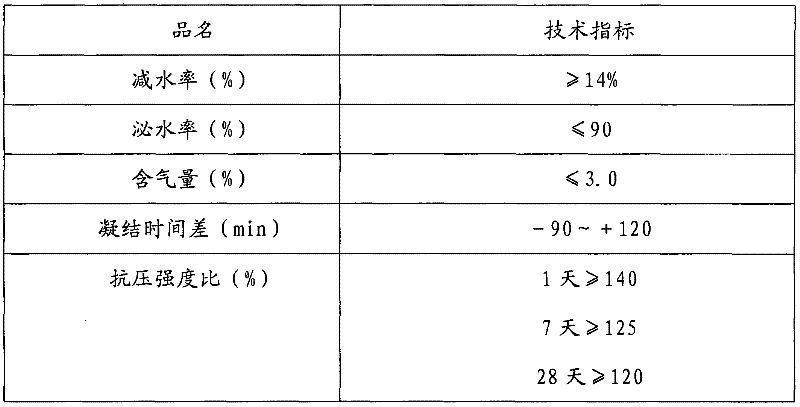

Image

Examples

Embodiment 1

[0028] A new type of melamine water reducer, the mass percentage of raw materials is:

[0029] Melamine 19%;

[0030] Paraformaldehyde 38%;

[0032] 30% sulfuric acid 2%;

[0033] Sodium hydroxide solution 3%;

[0034] Water 20%.

[0035] Add water, melamine, and formaldehyde solution in sequence to a reaction kettle equipped with a thermometer, a condenser, and an agitator, stir and raise the temperature to 50-60°C for 1 hour, and keep it at 60-75°C for 1 hour. After the methylolation reaction is completed , use sodium hydroxide solution to adjust the pH value of the solution to 8.5-9.5; put sodium bisulfite into the reaction kettle after methylolation, raise the temperature to 84°C, react at 84-90°C for 1 hour, and maintain the pH of the solution at 10-11; when the sulfonation reaction is finished, reduce the solution temperature to 50°C, adjust the pH value of the system to 5-6.5 with 30% sulfuric acid, continue the reaction for 1 hour, a...

Embodiment 2

[0037] A new type of melamine water reducer, the mass percentage of raw materials is:

[0038] Melamine 20%;

[0039] Paraformaldehyde 39%;

[0040] Sodium bisulfite 22%;

[0041] 30% sulfuric acid 2.4%;

[0042] Sodium hydroxide solution 3%;

[0043] Water 25%.

[0044] Add water, melamine, and formaldehyde solution in sequence to a reaction kettle equipped with a thermometer, a condenser, and an agitator, stir and raise the temperature to 50-60°C for 1 hour, and keep it at 60-75°C for 2 hours. After the methylolation reaction is completed , use sodium hydroxide solution to adjust the pH value of the solution to 8.5-9.5; put sodium bisulfite into the reaction kettle after methylolation, raise the temperature to 84°C, react at 84-90°C for 1 hour, and maintain the pH of the solution at 10-11; when the sulfonation reaction is finished, reduce the solution temperature to 50°C, adjust the pH value of the system to 5-6.5 with 30% sulfuric acid, continue the reaction for 1.5 ho...

Embodiment 3

[0046] A new type of melamine water reducer, the mass percentage of raw materials is:

[0047] Melamine 21%;

[0048] 20-28% formaldehyde solution 40%;

[0049] Sodium bisulfite 25%;

[0050] 30% sulfuric acid 2.5%;

[0051] Potassium hydroxide solution 4%;

[0052] Water 28%.

[0053] Add water, melamine, and formaldehyde solution in sequence to a reaction kettle equipped with a thermometer, a condenser, and an agitator, stir and raise the temperature to 50-60°C for 2 hours, and keep it at 60-75°C for 3 hours. After the methylolation reaction is completed , use potassium hydroxide solution to adjust the pH value of the solution to 8.5-9.5; put sodium bisulfite into the reaction kettle after methylolation, raise the temperature to 84°C, react at 84-90°C for 2 hours, and maintain the pH of the solution at 10-11; when the sulfonation reaction is finished, reduce the solution temperature to 50°C, adjust the pH value of the system to 5-6.5 with 30% sulfuric acid, continue the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com